Ceramic dielectric material and preparation method thereof

A technology for ceramic dielectric materials and raw materials is applied in the field of preparing the ceramic dielectric materials to achieve the effects of high dielectric constant, low dielectric loss and high breakdown electric field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

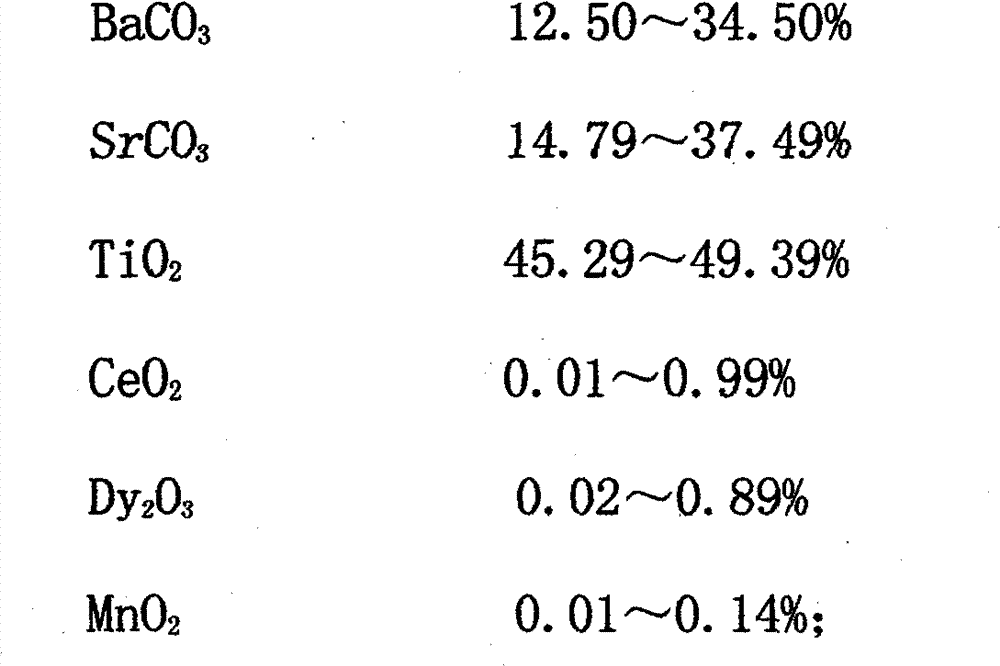

[0031] To prepare the ceramic dielectric material of the present invention, take the following components by molar percentage:

[0032] BaCO 3 34.50% SrCO 3 14.79%

[0033] TiO 2 49.29% CeO 2 0.99%

[0034] Dy 2 o 3 0.29% MnO 2 0.14%.

[0035] BaCO 3 , SrCO 3 and TiO 2 Carry out batching, obtain batching thing, according to batching thing: zirconia ceramic ball: the mass ratio of deionized water=1:1:2 is put into ball mill pot and carry out ball milling 24h; Ball mill is placed in charging pan and puts in drying equipment , dried at a temperature of 120°C, the dried material was placed in an alumina crucible, put into an electric furnace and pre-synthesized at 1080°C for 2 hours to synthesize (Ba,Sr)TiO 3 . Add CeO to the above synthetic material 2 、Dy 2 o 3 and MnO 2 , to obtain the mixture, and then according to the mixture: zirconia ceramic balls: water = 1: 1: 1.5, carry out secondary ball milling for 24h; put the ball grinding m...

Embodiment 2

[0037] To prepare the ceramic dielectric material of the present invention, take the following components by molar percentage:

[0038] BaCO 3 12.50% SrCO 3 37.49%

[0039] TiO 2 48.12% CeO 2 0.99%

[0040] Dy 2 o3 0.89% MnO 2 0.01%.

[0041] BaCO 3 , SrCO 3 and TiO 2 Carry out batching, obtain batching, according to batching: zirconia ceramic ball: the mass ratio of deionized water=1:1:2 is put into ball mill tank and carries out ball milling 4h; Ball mill is placed in charging pan and puts in drying equipment , dried at a temperature of 110°C, the dried material was placed in an alumina crucible, put into an electric furnace and pre-synthesized at 1100°C for 4 hours to synthesize (Ba,Sr)TiO 3 . Add CeO to the above synthetic material 2 、Dy 2 o 3 and MnO 2 , to obtain the mixture, and then according to the mixture: zirconia ceramic balls: water = 1: 1: 1.5, carry out secondary ball milling for 6h; put the ball grinding material in the tray, and ...

Embodiment 3

[0043] To prepare the ceramic dielectric material of the present invention, take the following components by molar percentage:

[0044] BaCO 3 25.9% SrCO 3 25%

[0045] TiO 2 48% CeO 2 0.5%

[0046] Dy 2 o 3 0.5% MnO 2 0.1%.

[0047] BaCO 3 , SrCO 3 and TiO 2 Carry out batching, obtain batching, according to batching: zirconia ceramic ball: the mass ratio of deionized water=1:1:2 is put into ball mill tank and carries out ball milling 4h; Ball mill is placed in charging pan and puts in drying equipment , dried at a temperature of 130°C, the dried material was placed in an alumina crucible, put into an electric furnace and pre-synthesized at 1020°C for 3 hours to synthesize (Ba,Sr)TiO 3 . Add CeO to the above synthetic material 2 、Dy 2 o 3 and MnO 2 , to obtain the mixture, and then according to the mixture: zirconia ceramic balls: water = 1: 1: 1.5, carry out secondary ball milling for 12h; put the ball grinding material in the tray, and dry it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com