Barium-zinc liquid stabilizer, preparation method and application thereof

A liquid stabilizer, barium-zinc technology, applied in the field of thermal stabilizer for decorative PVC materials and its preparation, can solve the problems of high price, complicated preparation process, peculiar smell of products, etc., achieve a large price advantage, simplify the production process, Energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

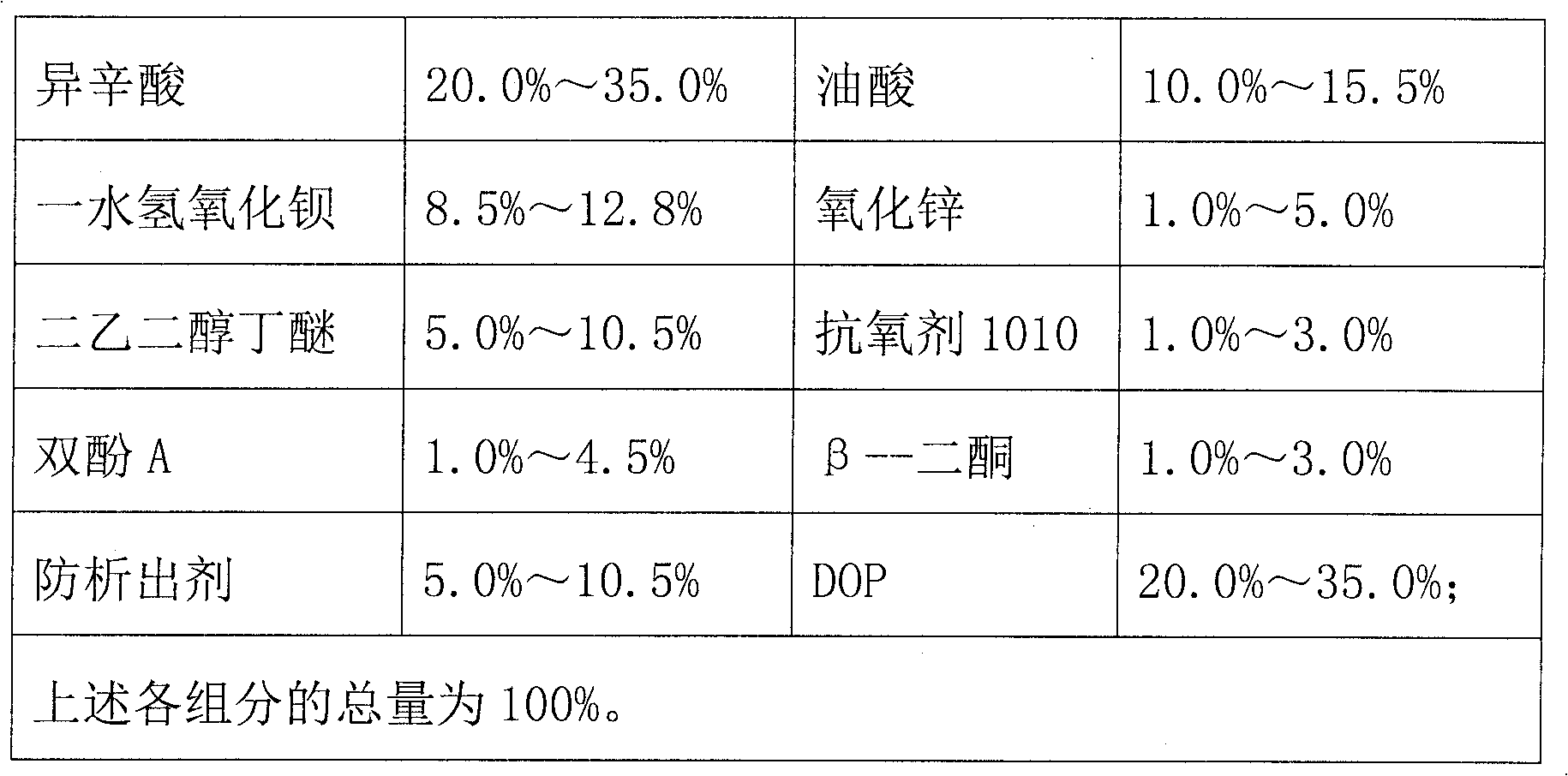

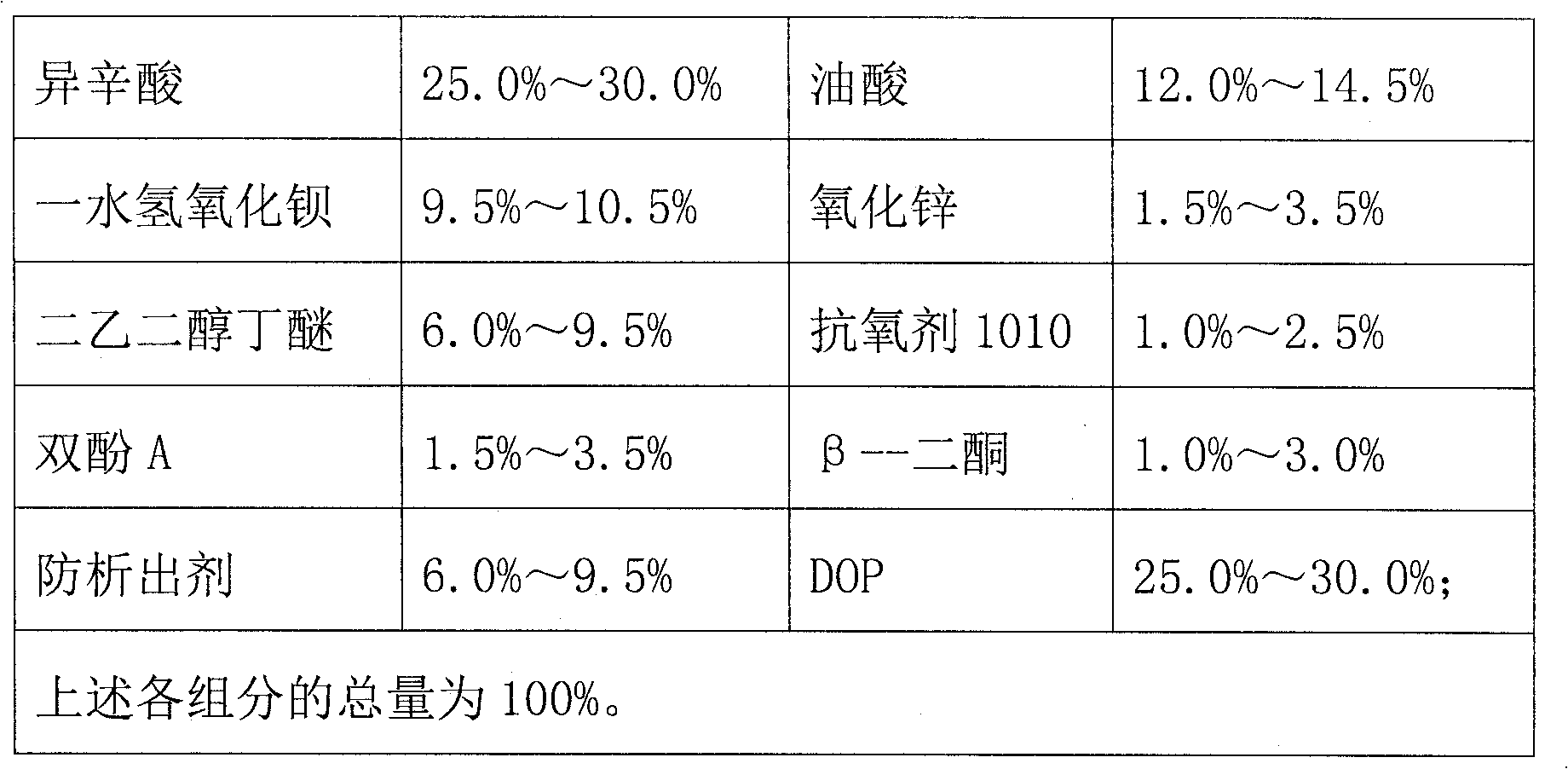

[0028] A kind of barium-zinc liquid stabilizer, the raw material of this liquid stabilizer is made up of following components by weight percentage:

[0029] isooctanoic acid

28.5%

12.5%

9.8%

4.2%

Diethylene glycol butyl ether

6.5%

Antioxidant 1010

1.5%

3.5%

β--diketone

2.0%

Anti-leaching agent

7.5%

DOP

24.0%。

[0030] The preparation method of above-mentioned barium-zinc liquid stabilizer, this method comprises the following steps:

[0031] ①Put isooctanoic acid, oleic acid, barium hydroxide monohydrate, zinc oxide and part of diethylene glycol butyl ether into the reaction kettle, stir and heat up to 90°C, and keep it warm for 2 hours until the reaction is complete;

[0032] ② After the reaction is complete and the solution becomes transparent, heat up to 100°C for vacuum dehydration;

[0033] ③After ...

Embodiment 2

[0036] A kind of barium-zinc liquid stabilizer, the raw material of this liquid stabilizer is made up of following components by weight percentage:

[0037] isooctanoic acid

21.8%

14.2%

11.2%

Zinc oxide

3.5%

Diethylene glycol butyl ether

9.6%

Antioxidant 1010

2.4%

1.8%

β--diketone

2.4%

Anti-leaching agent

6.2%

DOP

26.9%。

[0038] The preparation method of above-mentioned barium-zinc liquid stabilizer, this method comprises the following steps:

[0039] ①Put isooctanoic acid, oleic acid, barium hydroxide monohydrate, zinc oxide and part of diethylene glycol butyl ether into the reaction kettle, stir and heat up to 90°C, and keep it warm for 2 hours until the reaction is complete;

[0040] ② After the reaction is complete and the solution becomes transparent, heat up to 100°C for vacuum dehydration;

[0041] ③After...

Embodiment 3

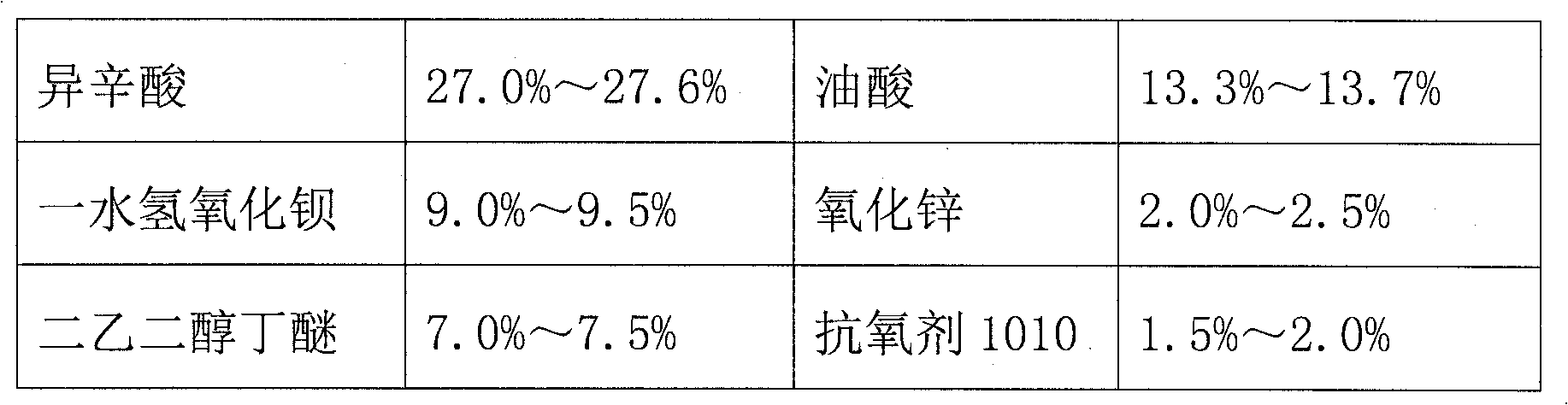

[0044] A kind of barium-zinc liquid stabilizer, the raw material of this liquid stabilizer is made up of following components by weight percentage:

[0045] isooctanoic acid

27.3%

13.5%

9.2%

Zinc oxide

2.3%

Diethylene glycol butyl ether

7.2%

Antioxidant 1010

1.8%

2.4%

β--diketone

2.0%

Anti-leaching agent

7.3%

DOP

27.0%;

[0046] The preparation method of above-mentioned barium-zinc liquid stabilizer, this method comprises the following steps:

[0047] ①Put isooctanoic acid, oleic acid, barium hydroxide monohydrate, zinc oxide and part of diethylene glycol butyl ether into the reaction kettle, stir and heat up to 90°C, and keep it warm for 2 hours until the reaction is complete;

[0048] ② After the reaction is complete and the solution becomes transparent, heat up to 100°C for vacuum dehydration;

[0049] ③After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com