High-temperature pressure-bearing composite insulator composition of corrosion-resistant gas and preparation method thereof

An insulator and corrosion-resistant technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve problems affecting the service life and corrosion of petroleum logging instruments, so as to save logging time, prolong service life, and improve logging speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

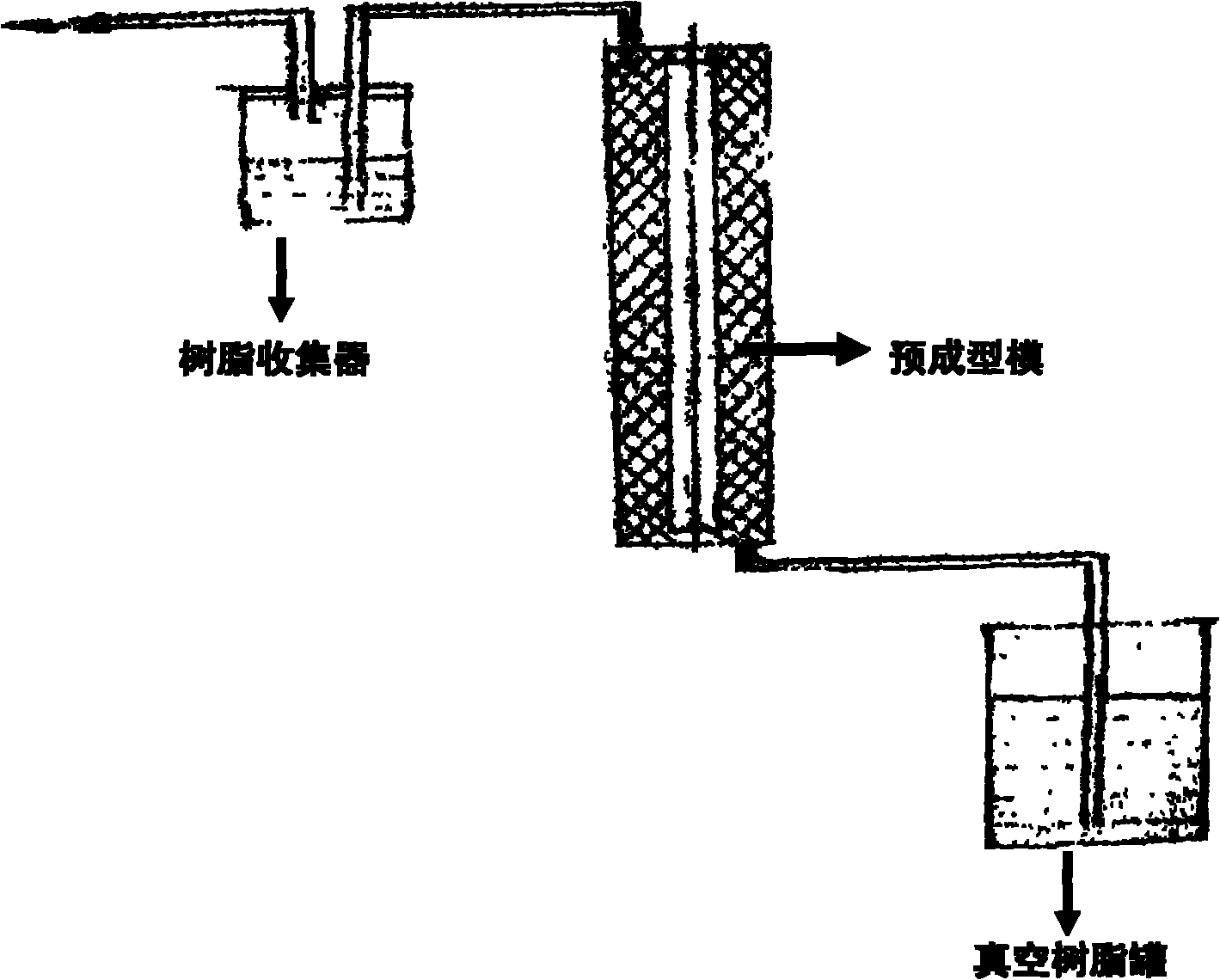

[0039] A method for preparing composite insulators is carried out according to the following steps:

[0040] 1), the choice of glass fiber yarn

[0041] The glass fiber yarn uses boron-free, alkali-free and twist-free direct yarn, and its fiber specification ranges from 600tex-2400tex. All glass fiber yarns must be covered with a special sizing agent;

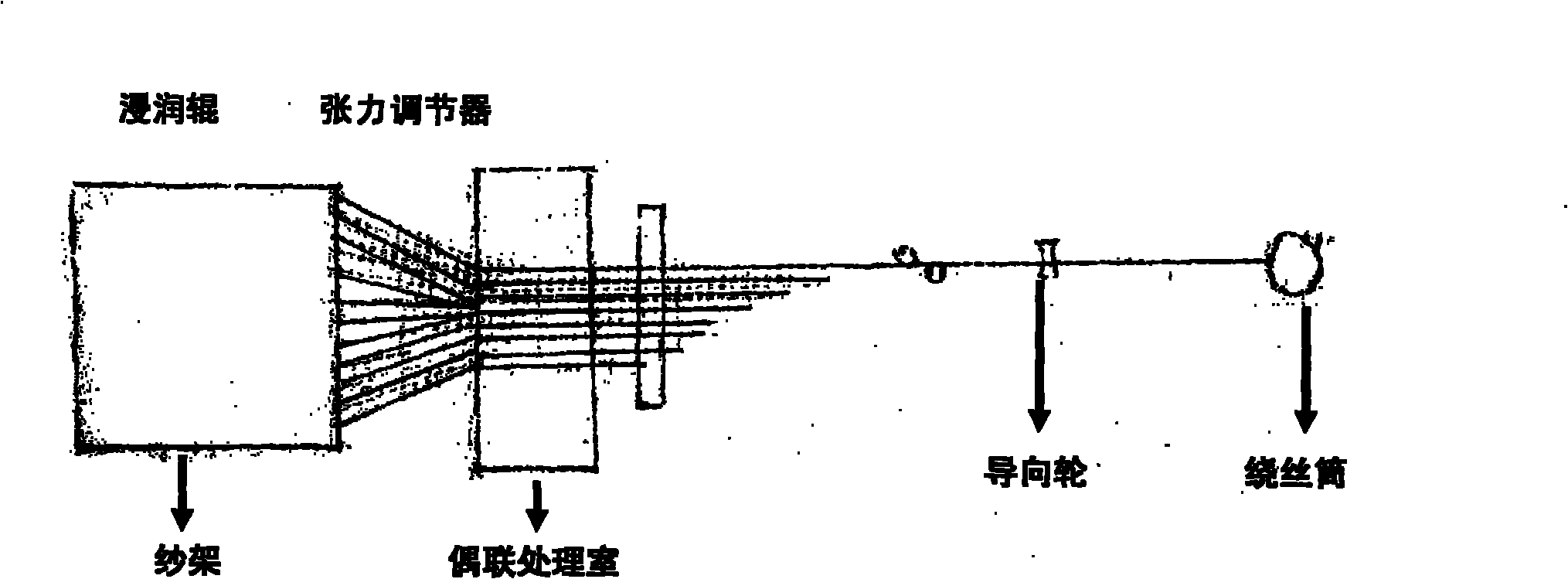

[0042] 2) Surface treatment of glass fiber yarn

[0043] Because of the significant gaps between the glass fiber yarn and the resin interface, the capillary action causes water to penetrate into the composite along the interface, and further weakens the bond between the resin and the glass fiber yarn, which reduces the physical and chemical properties of the composite material. For this, use KH560, Y-aminopropyl triethoxysilane NH 2 -CH 2 -CH 2 -CH 2 -Si-COC 2 H 5 As a glass fiber yarn coupling agent; the mass ratio of coupling agent to glass fiber yarn is coupling agent: glass fiber yarn = 1.5 parts to 2.5 parts: 98.5 parts to 97.5 pa...

Embodiment 1

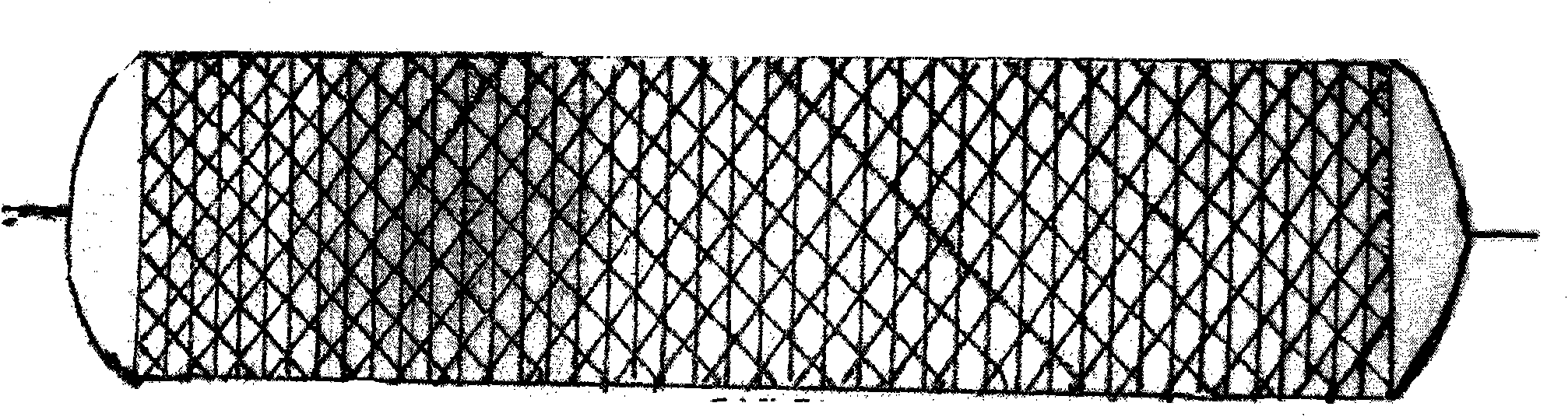

[0064] A pressure-bearing composite insulator composition capable of resisting corrosion gas. The composite insulator composition is composed of 75 parts to 85 parts of glass fiber yarn and 25 parts to 15 parts of resin glue in a mass ratio.

[0065] A method for preparing composite insulators is carried out according to the following steps:

[0066] 1), the choice of glass fiber yarn

[0067] Glass fiber yarn uses boron-free, alkali-free, non-twist and acid-resistant direct yarn, and its fiber specification ranges from 600tex-2400tex. All glass fiber yarns used must be covered with a special sizing agent;

[0068] 2) Surface treatment of glass fiber yarn

[0069] Because of the significant gaps between the glass fiber yarn and the resin interface, the capillary action causes water to penetrate into the composite along the interface, and further weakens the bond between the resin and the glass fiber yarn, which reduces the physical and chemical properties of the composite material. For...

Embodiment 2

[0093] A pressure-bearing composite insulator composition capable of resisting corrosive gas. The composite insulator composition is composed of 77 to 83 parts of glass fiber yarn and 23 to 17 parts of resin glue in a mass ratio.

[0094] A method for preparing composite insulators is carried out according to the following steps:

[0095] 1), the choice of glass fiber yarn

[0096] Glass fiber yarn uses boron-free, alkali-free, non-twist and acid-resistant direct yarn, and its fiber specification ranges from 600tex-2400tex. All glass fiber yarns used must be covered with a special sizing agent;

[0097] 2) Surface treatment of glass fiber yarn

[0098] Because of the significant gaps between the glass fiber yarn and the resin interface, the capillary action causes water to penetrate into the composite along the interface, and further weakens the bond between the resin and the glass fiber yarn, which reduces the physical and chemical properties of the composite material. For this, use K...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com