Chemical composition plating method for preparing supported platinum bimetallic alloy composite material

A technology for chemical composite plating and composite materials, applied in the field of bimetallic alloy material preparation, can solve the problems of complex preparation process and high cost, and achieve the effects of good preparation repeatability, low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

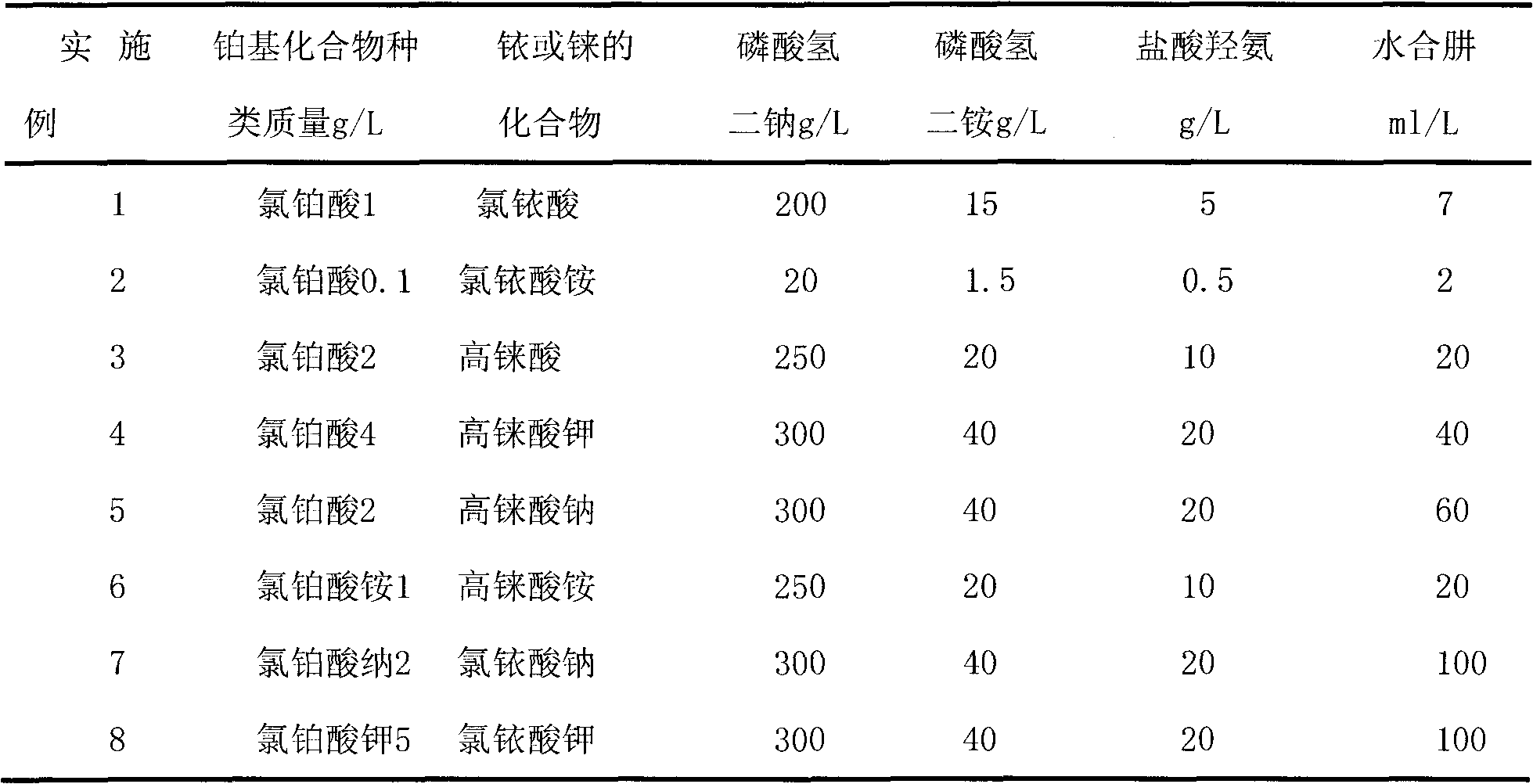

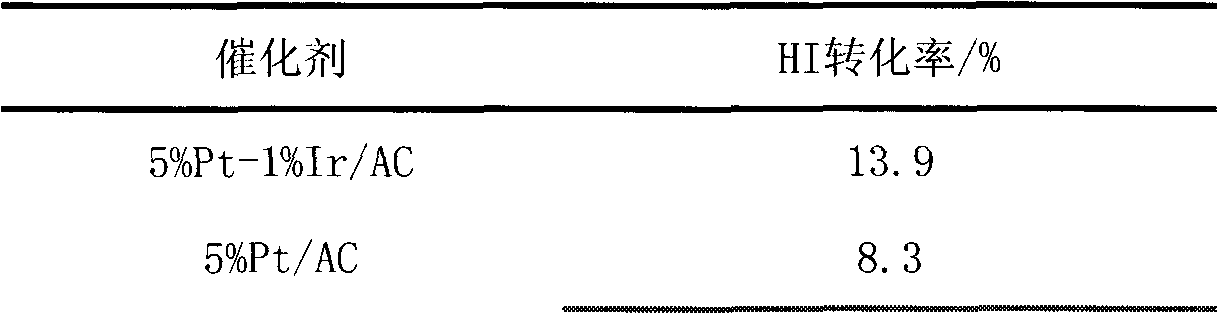

Examples

Embodiment 1

[0039] Embodiment 1 prepares platinum-iridium bimetallic composite material 5%Pt-1%Ir / activated carbon

[0040] Activated carbon was heat-treated at 120°C for 4 hours; then, by dipping, the heat-treated substrate was dipped in platinum sensitizing solution-chloroplatinic acid aqueous solution, and dried at 120°C to obtain the pre-activated body, wherein platinum for sensitization accounts for 1% of the mass of activated carbon; the resulting activated precursor is added to KBH 4 Reduction is carried out in the solution, the molar ratio of the reducing agent to the activated noble metal in the activated precursor is 20:1, the reduction time is 5 minutes, and the activated precursor after the reduction is washed with deionized water until the washing solution is neutral, that is, obtained Substrate after activation; The substrate after the gained activation is directly placed in the platinum-iridium bimetallic alloy electroless plating bath and carries out electroless plating, a...

Embodiment 2

[0041] Embodiment 2 prepares platinum-iridium bimetallic composite material 1%Pt-50%Ir / Al 2 o 3

[0042] Will Al 2 o 3 Heat treatment at 450°C for 2 hours; then, use the dipping method to dip the heat-treated substrate into iridium sensitizing solution-chloroiridic acid aqueous solution, and dry at 200°C to obtain an activated precursor, wherein Sensitization with iridium accounted for Al 2 o 3 5% by mass; the resulting activated precursor was added to NaBH 4 Reduction is carried out in the solution, the molar ratio of the reducing agent to the activated noble metal in the activated precursor is 10:1, the reduction time is 60 minutes, and the activated precursor after the reduction is washed with deionized water until the washing solution is neutral, that is, obtained Substrate after activation; The substrate after the gained activation is directly placed in the platinum-iridium bimetallic alloy electroless plating solution and carries out electroless plating, and platin...

Embodiment 3

[0043] Embodiment 3 prepares platinum-rhenium bimetallic composite material 10%Pt-0.1%Re / CeO 2 -ZrO 2

[0044] CeO 2 -ZrO 2 Heat treatment at 500°C for 2 hours; then, use the impregnation method to dip the heat-treated substrate into the platinum sensitizing solution-ethanol solution of chloroplatinic acid, and dry it at room temperature to obtain the activated precursor. Among them, the sensitization uses platinum to account for CeO 2 -ZrO 2 1% of the mass; the obtained activated precursor is added to the hydrazine hydrate solution for reduction, the molar ratio of the reducing agent to the activated noble metal in the activated precursor is 20:1, the reduction time is 30 minutes, and the deionized water is used for washing and reducing After the activation of the precursor, until the washing solution is neutral, the substrate after the activation is obtained; the substrate after the activation is directly placed in the platinum-iridium bimetallic alloy electroless plati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com