Self-convection radiating type water-electrolyzing hydrogen-oxygen generator

A gas generator and self-convection technology, which is applied to electrolytic components and electrolytic processes, can solve the problems of difficult manufacturing, high cost, and large equipment volume, and achieve the effects of simple manufacturing process, reduced energy consumption, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

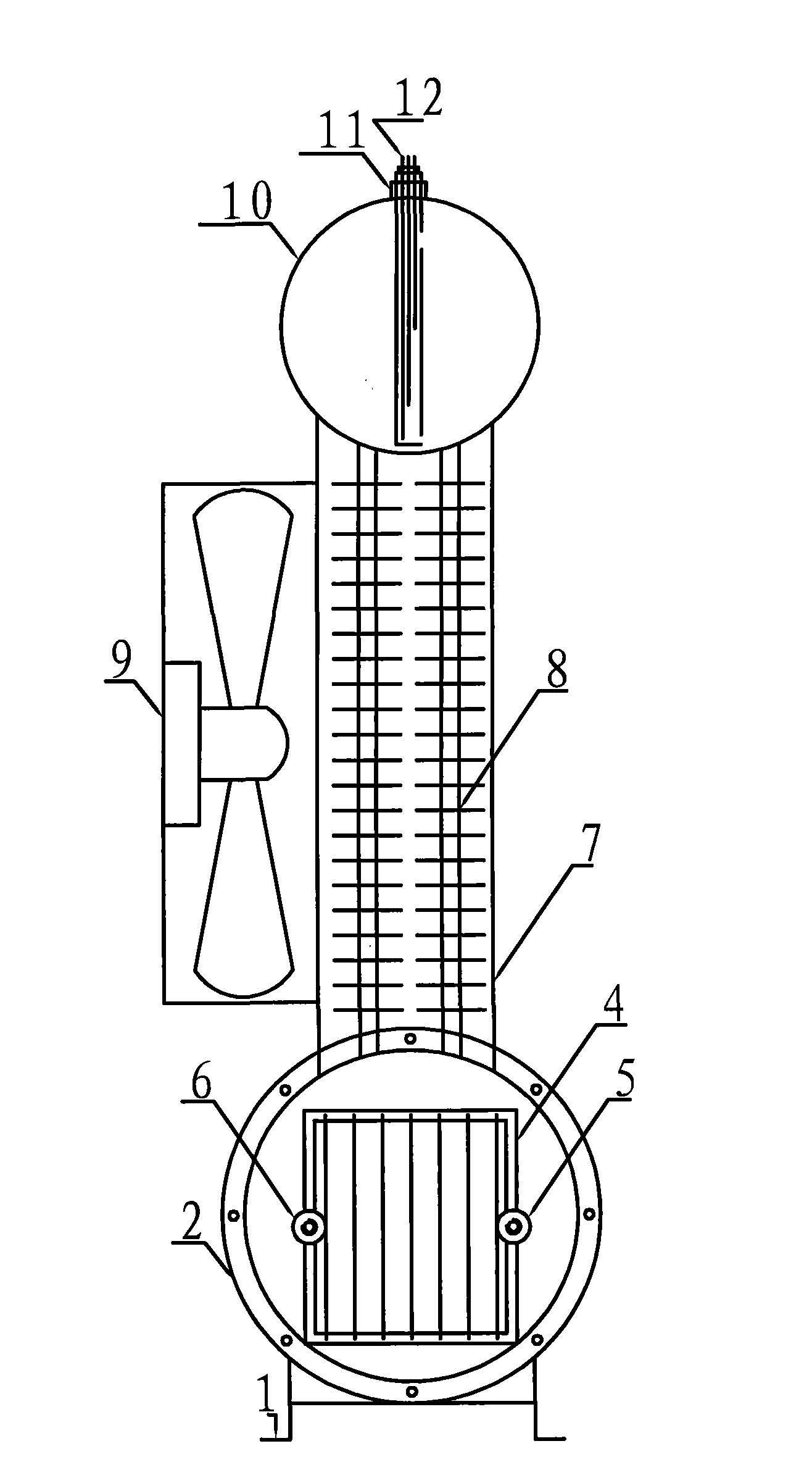

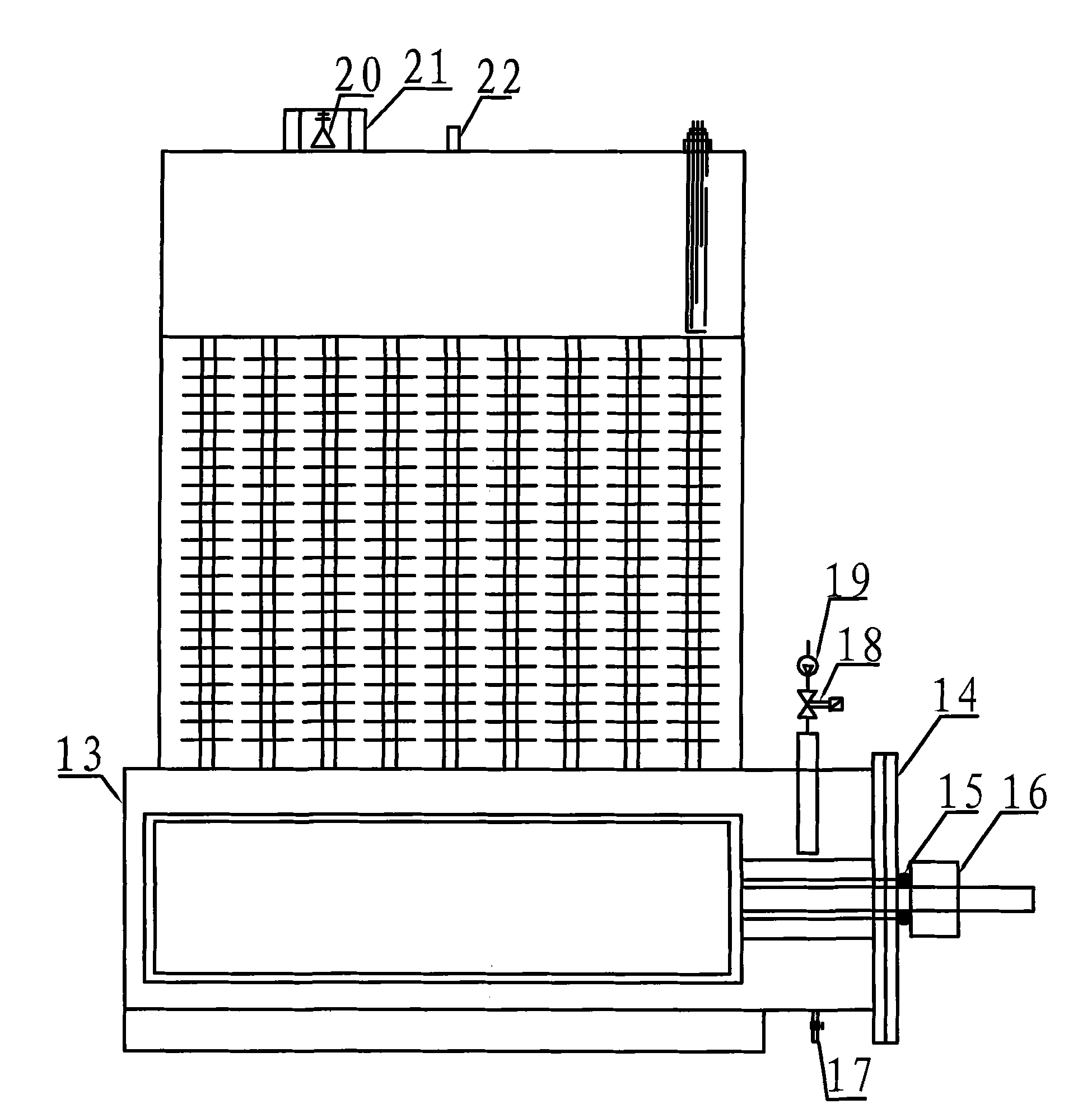

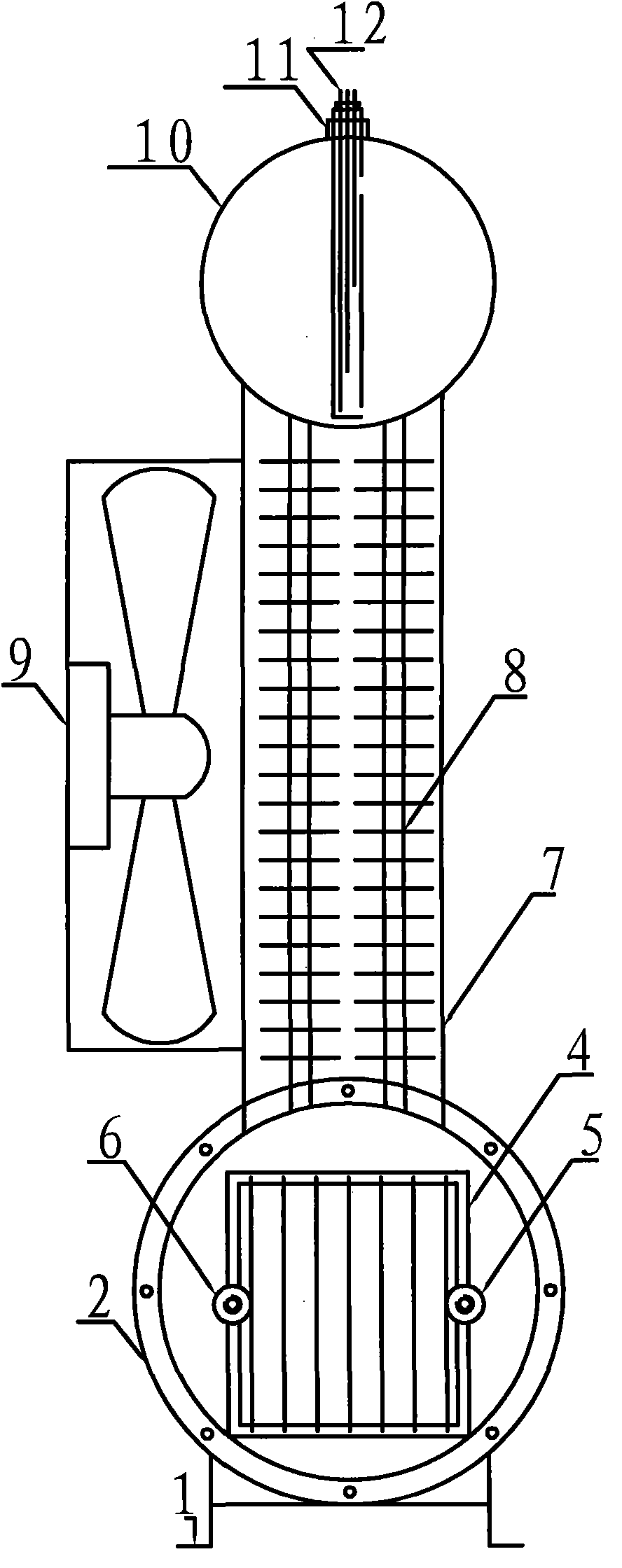

[0024] like figure 1 , figure 2 As shown, the present invention includes an electrolyte storage tank 13 installed on the chassis 1, a flange 2 is provided on one side of the electrolyte storage tank 13; an electrolysis chamber 4 is installed inside, and the two sides of the electrolysis chamber 4 are respectively provided with Positive terminal 5 and negative terminal 6, the outside of the positive terminal 5 and negative terminal 6 is covered with an electrode insulating sleeve 11, and the positive terminal 5 and negative terminal 6 protrude from the flange cover 14, and its extension The outlet is sealed with a sealing ring 15 and a fastening nut 16 . The upper end of the electrolyte storage tank 13 is fixedly connected to a self-convection cooling system composed of several self-convection heat dissipation pipes 8, air ducts 7, axial flow fans 9, and self-convection water tanks 10. The self-convection heat dissipation pipes 8 are distributed in the air duct 7. , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com