Heat transfer and combustion enhanced gas stove

A gas stove and burner technology, applied in the field of stoves, can solve problems such as incomplete combustion, excessive CO, and unhygienic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

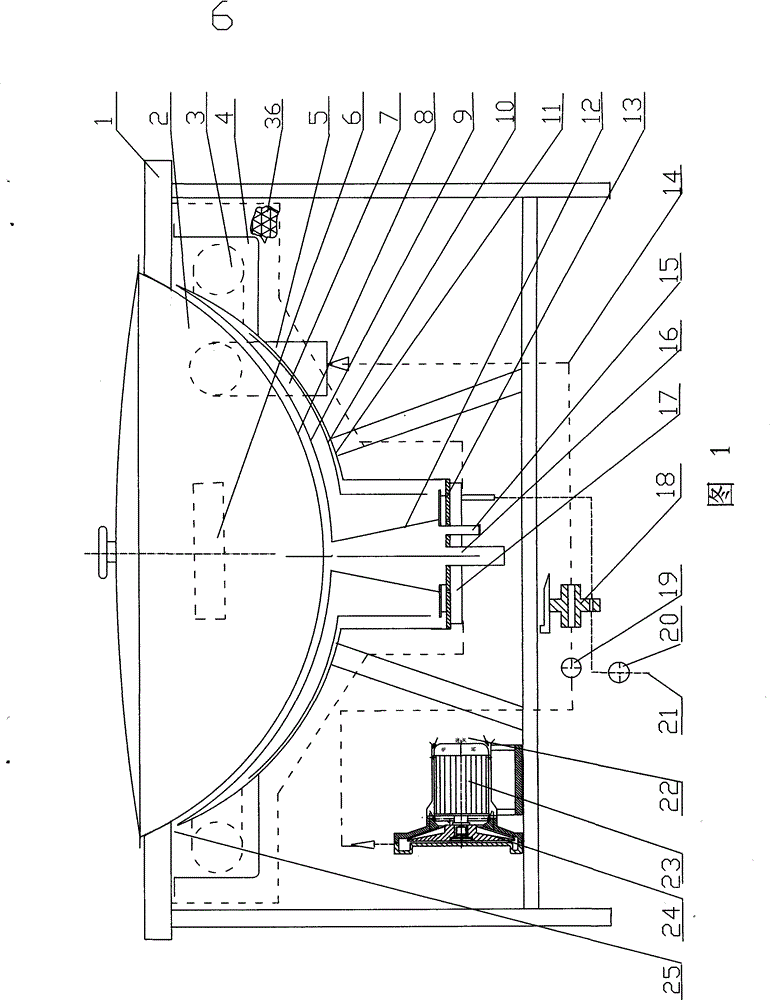

[0010] The specific implementation manner of saying here is to introduce a manufacture such as Figure 1 Shown is a gas stove with enhanced heat transfer and combustion. The diameter of the pot is Φ320, the depth of the pot is 122mm, it is filled with 3.8Kg of water, the heating area at the bottom of the pot is 0.11m2, and the following recommended structural dimensions, they will vary depending on the stove There are some variations depending on the size and usage. Next, we will introduce its comparison with traditional stoves under the same experimental conditions.

[0011] according to figure 1 , The molded line furnace is formed by stamping and rolling welding of 0.6mm steel plate, and the distance between the inner plate (9) and the bottom surface of the pot (8) is recommended to be 3mm.

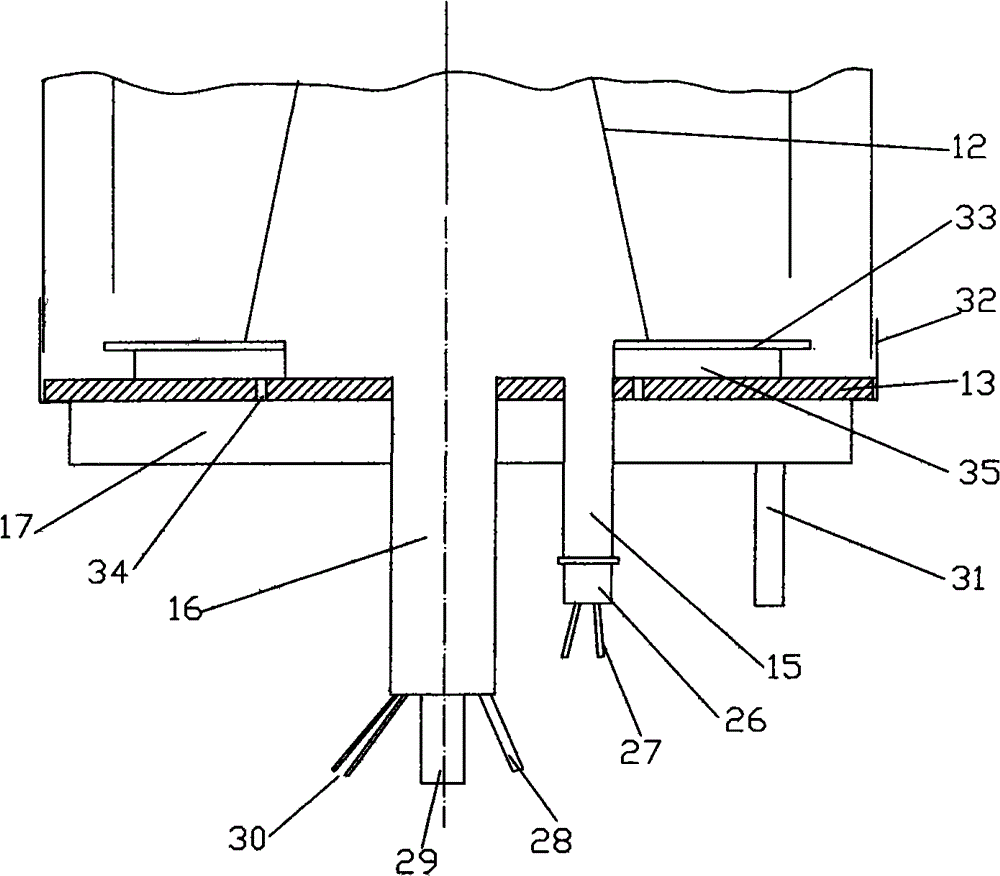

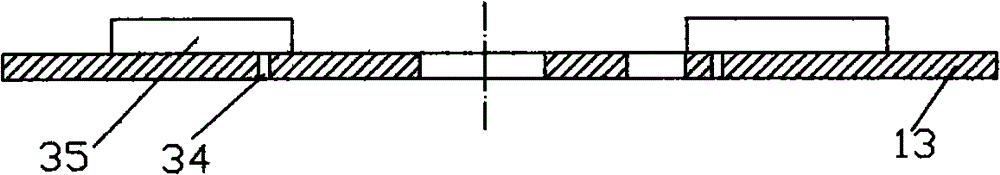

[0012] according to figure 2 , 3 , 4, the burner blade (35) is 2.5mm high, sixteen pieces, fuel air holes (34) sixteen, diameter 1.5mm, the position is near the outlet of the casca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com