Main chain tension predicting control system of paraffin continuous shaping machine

A technology of predictive control and main chain, applied in control/adjustment system, mechanical pressure/force control, single motor speed/torque control, etc., it can solve the damage of main chain wax tray frame and wax tray, and failure to display faults accurately and in time. point, reduce the effective start-up time, etc., to avoid adverse consequences, improve equipment efficiency, and take up less space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

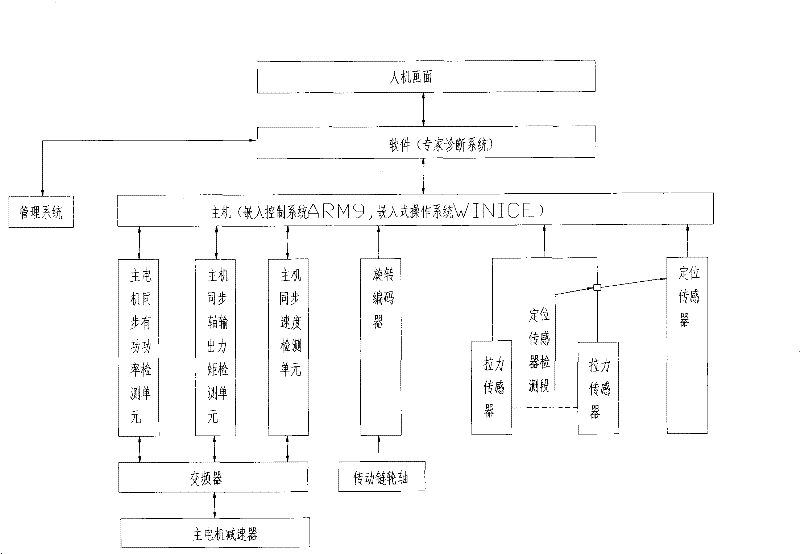

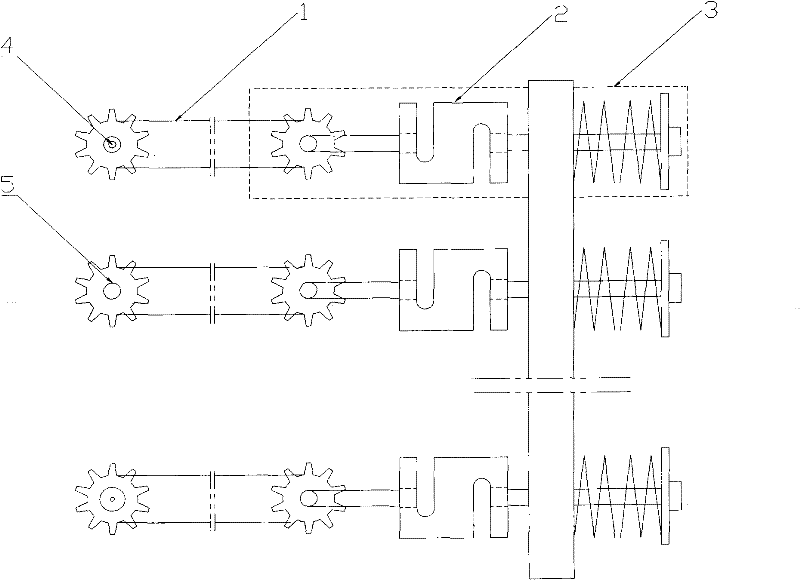

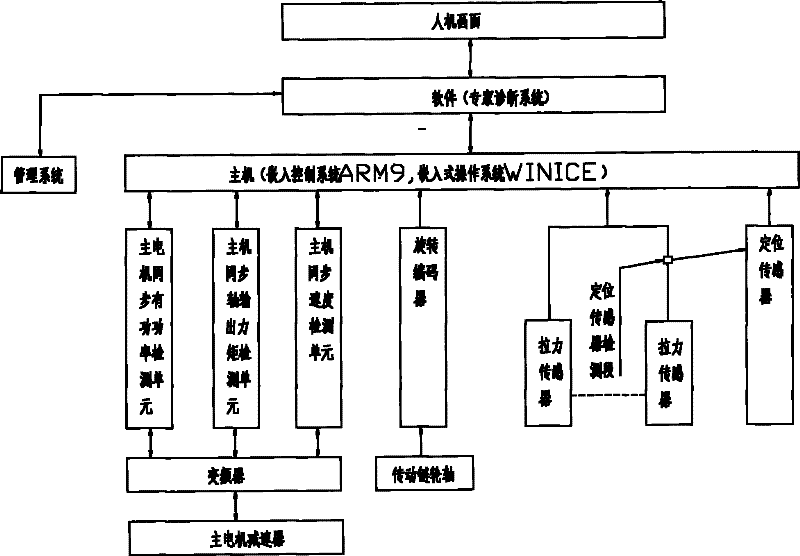

[0030] Such as figure 1 As shown, the main structure of the tension prediction control system is mainly composed of: frequency converter, rotary encoder, tension sensor detection element, host, signal transmission and processing device, configuration software and expert diagnosis software system, and thus constitute the system Body coordinate system.

[0031] This system constitutes the subsystem of the whole control system of the continuous paraffin wax molding machine, which is centrally installed in the same control cabinet for unified coordination and can be operated independently.

[0032] When the paraffin wax continuous molding machine is working, the main chain tension prediction control system enters the running state.

[0033] Embedded in the host computer is the advanced control technology embedded control system ARM9 in the field of control today; signal transmission and processing mainly include the operating system WIN-CE, which is embedded in the host computer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com