Method for preparing monodispersed cuprous sulfide semiconductor nanocrystalline

A technology of cuprous sulfide and semiconductor, which is applied in the direction of copper sulfide, nanostructure manufacturing, nanotechnology, etc., and can solve problems such as complex operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

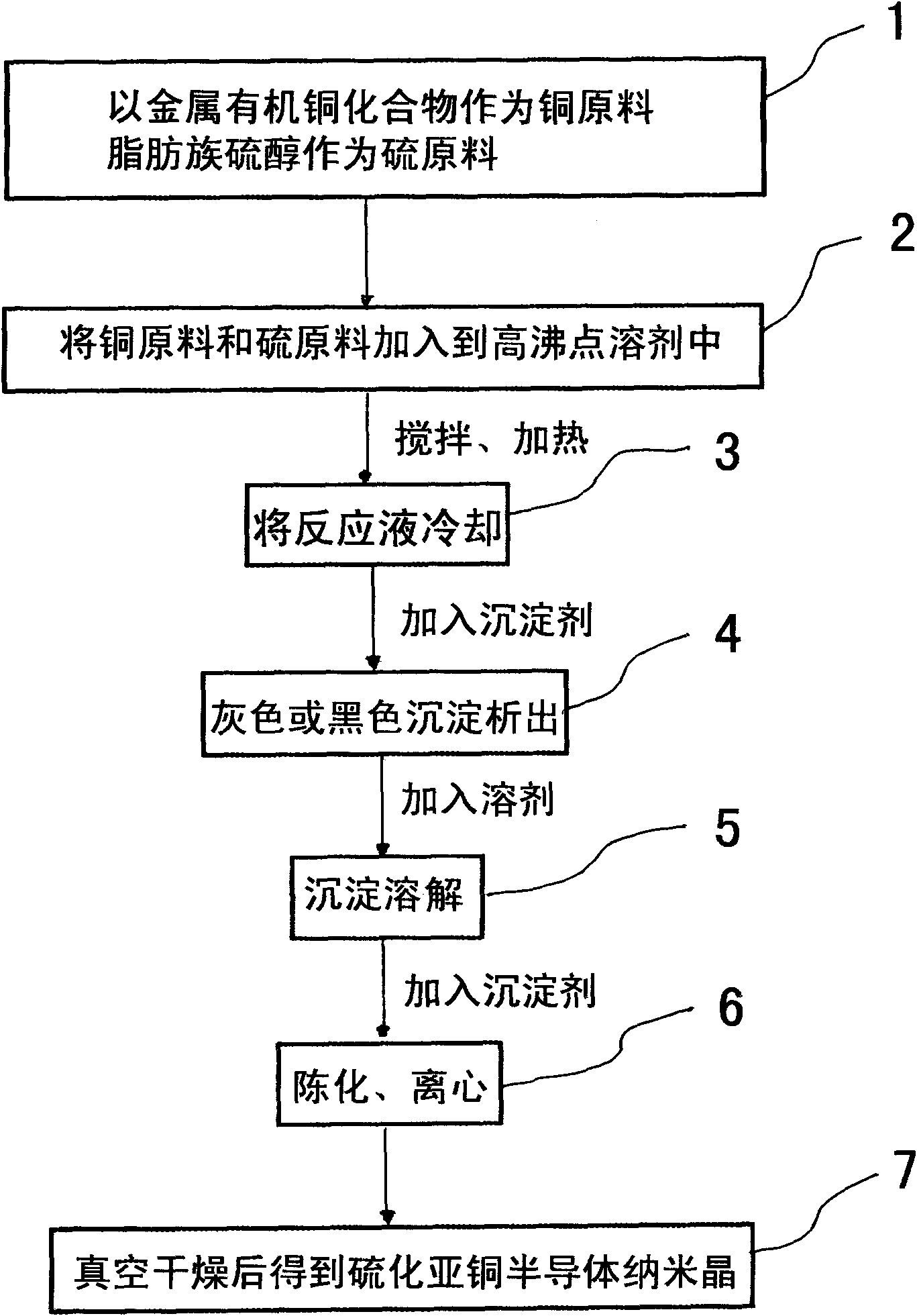

[0027] see figure 1 Shown, the present invention provides a kind of preparation method of monodisperse cuprous sulfide semiconductor nanocrystal, comprises the steps:

[0028] Step 1: Use metal organic copper compounds as copper raw materials, aliphatic mercaptans as sulfur raw materials, no need to prepare precursors of copper raw materials in advance, and the reaction operation is simple; wherein, the metal organic copper compounds are copper acetylacetonate, copper acetate or hard One of copper fatty acid; the aliphatic mercaptan is one of dodecyl mercaptan, cetyl mercaptan or octadecyl mercaptan;

[0029] Step 2: adding the copper raw material and the sulfur raw material together into a high boiling point solvent, stirring evenly, and performing a heating reaction to obtain a reaction liquid, which gradually changes from turbid to a clear solution, and then becomes turbid again; wherein, the The reaction temperature is 180-240°C, and the reaction time is 10 minutes-4 hour...

Embodiment 1

[0036] 3 millimoles of copper acetylacetonate and 10 milliliters of dodecanethiol were added to 20 milliliters of oleylamine, and the reaction solution was slowly heated to 200 ° C, and reacted for 120 minutes under magnetic stirring. After the reaction was completed, it was naturally cooled to room temperature. Add ethanol to the reaction solution for precipitation, then add chloroform solvent to the precipitate to dissolve to obtain a solution, then add ethanol to the solution, after aging and centrifugation, vacuum-dry the obtained sample at 70°C After 6 hours, cuprous sulfide nanocrystals were obtained.

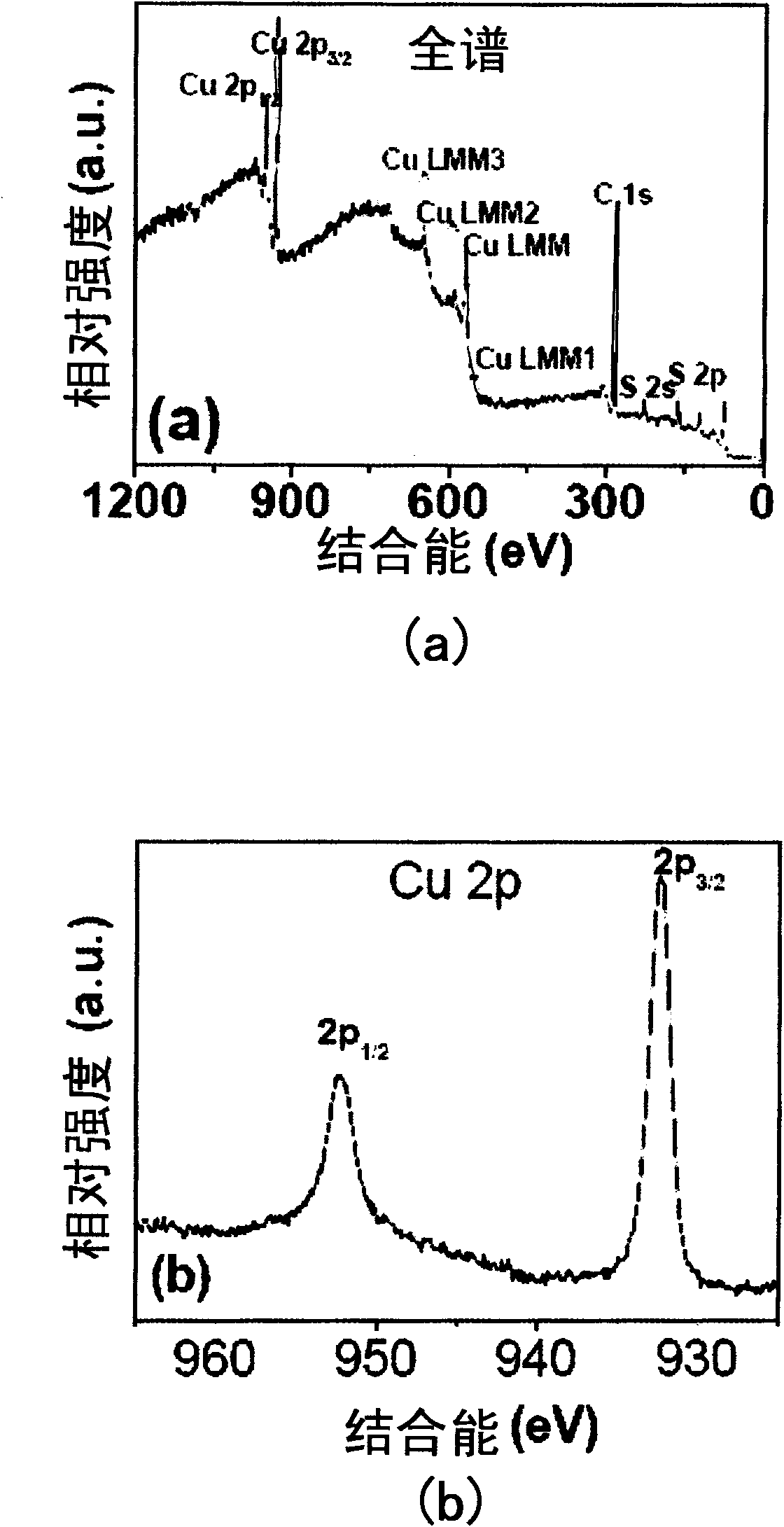

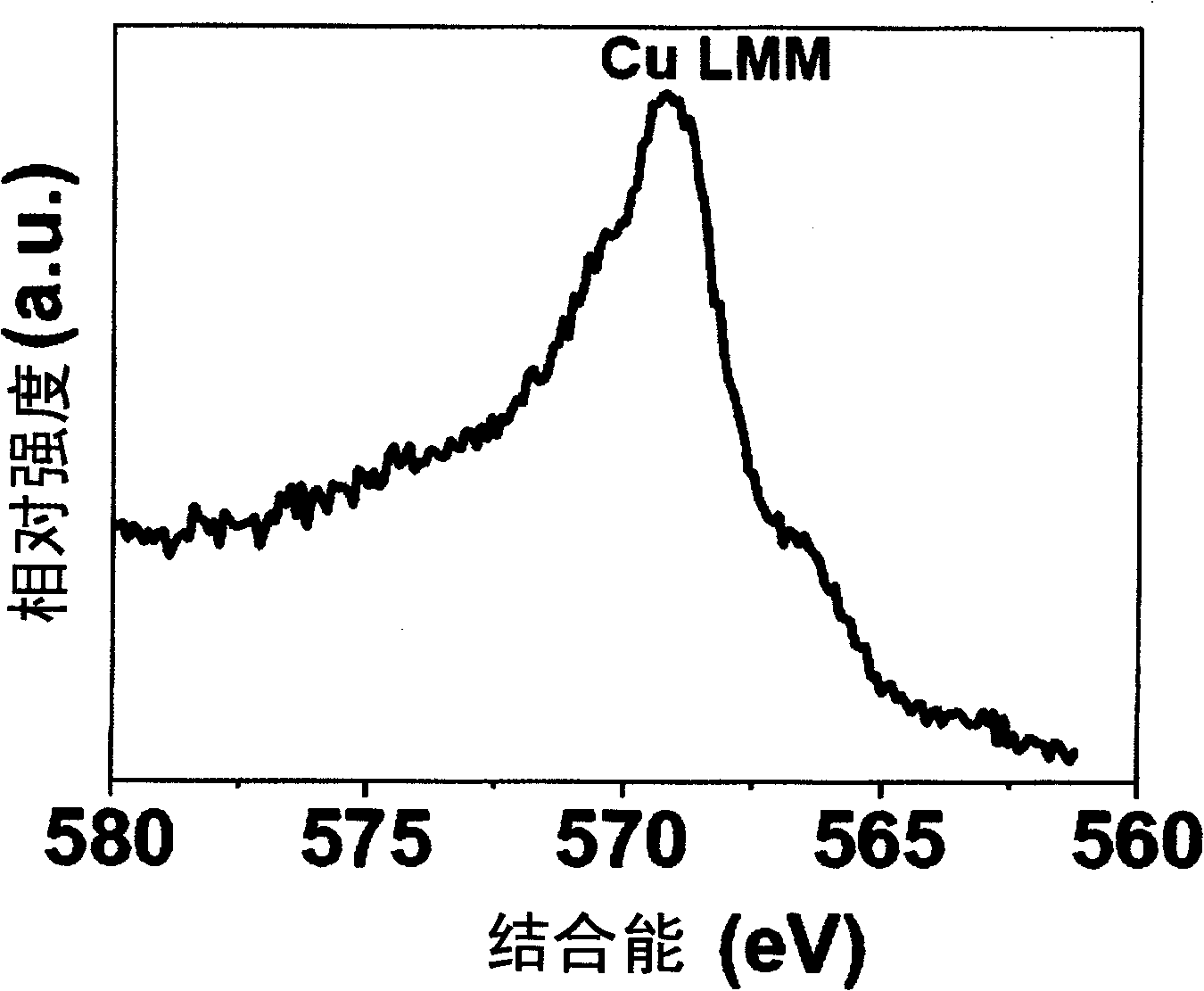

[0037] figure 2 and image 3 are respectively the X-ray photoelectron spectrum and the Auger electron spectrum of the cuprous sulfide semiconductor nanocrystal prepared in this embodiment, wherein figure 2 (b) Energy spectrum of Cu 2p and image 3 The Auger electron spectrum in all proves that the valence state of Cu element is +1. Figure 4 It is the X-ray powder d...

Embodiment 2

[0039] 3 millimoles of copper acetylacetonate and 5 milliliters of dodecanethiol were jointly added in 25 milliliters of oleylamine, and all the other operations were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com