Method for preparing 2-chloro-1,3-butadiene from 1,3-dichloro-2-butene by adopting thermal cracking

A technology of pyrolysis and butadiene, applied in the direction of chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve the problems of polluting the environment, wasting materials, etc., to solve environmental pollution problems, increase economic and social benefits obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

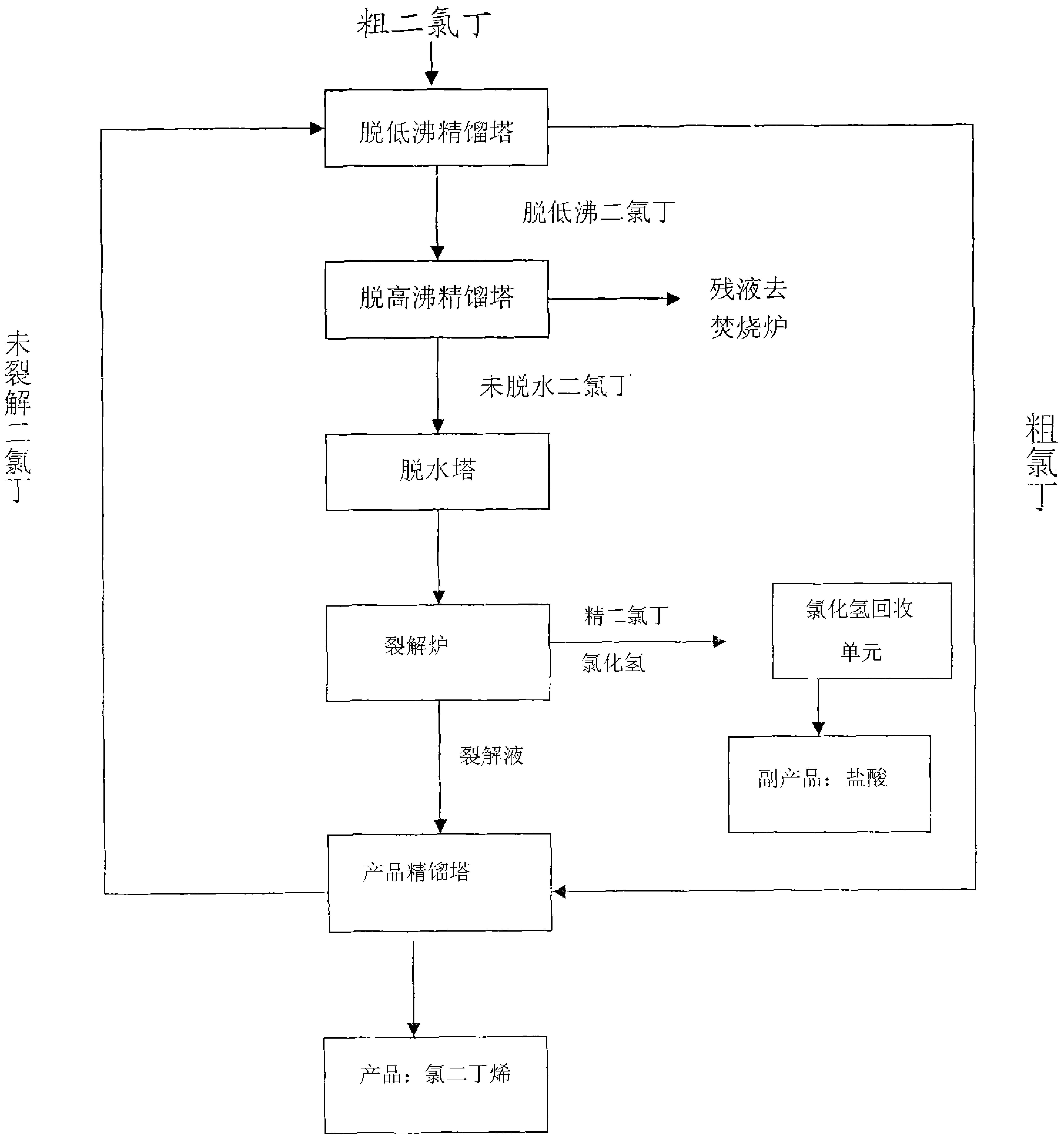

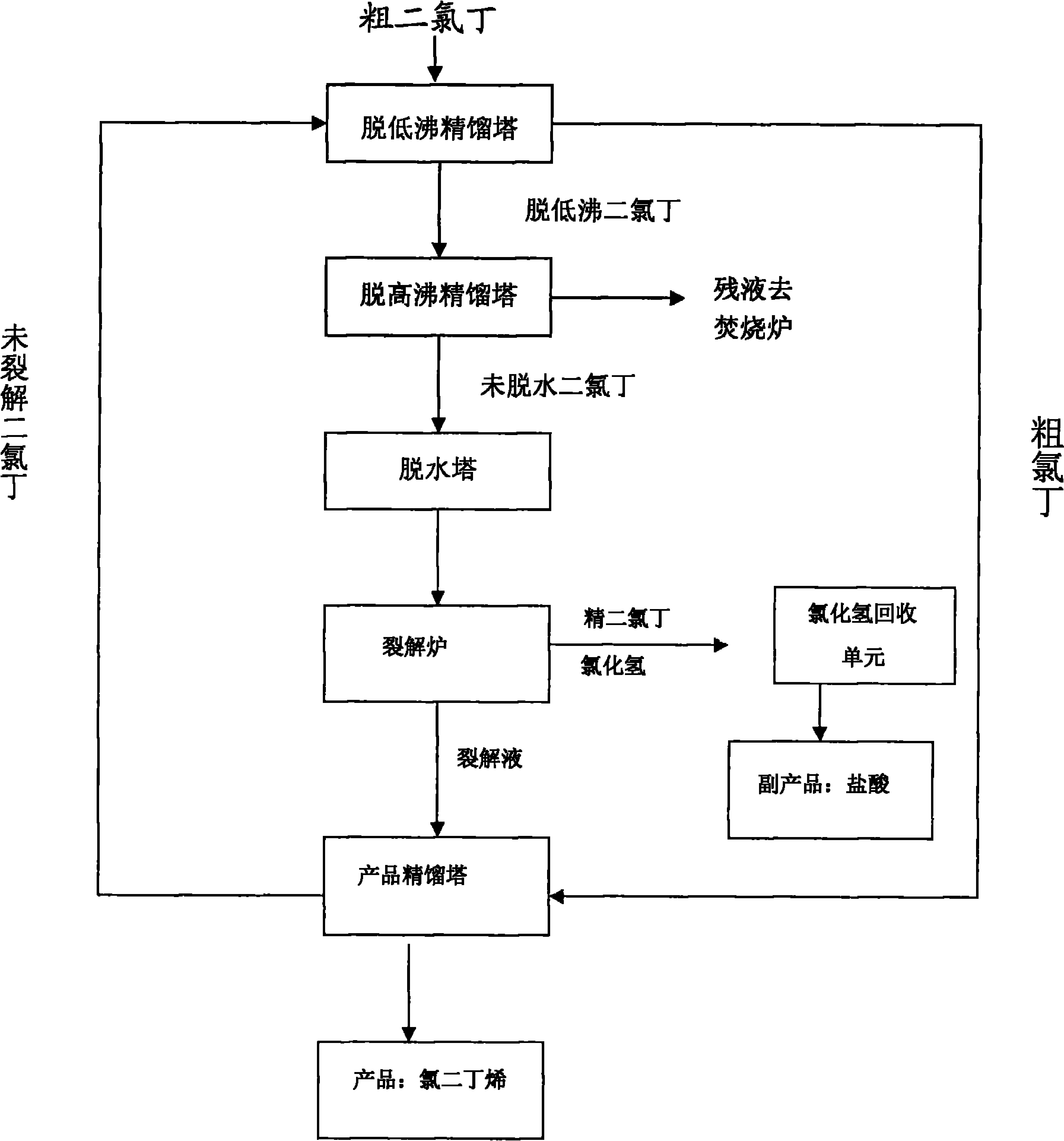

[0037] The inventive method has the following steps: (see figure 1 )

[0038] (1) Distillation and purification of raw materials

[0039] The raw material (crude 1,3-dichloro-2-butene) is sent to the low-boiling rectification tower through a pipeline to remove low-boiling substances (low-boiling substances refer to substances with a lower boiling point than dichlorobutene, such as benzene, chlorine butyl, acetaldehyde, etc.), the specific process is: put the raw material in the large storage tank of dichlorobutane, transfer it to the circulating dichlorobutane tank through the Φ57 stainless steel pipe, and then enter the low boiling point removal tank from the circulating dichlorobutane tank through the feeding pump Distillation tower.

[0040] According to the conditions in Table 1, the temperature, pressure and vacuum degree in the low-boiling distillation column are controlled to remove low-boiling substances such as benzene and chloroprene.

[0041] Table 1 Refining of ...

Embodiment 2

[0064] In this example, except that the dehydration method of 1,3-dichloro-2-butene in step (1) is different from that of Example 1, the remaining steps and conditions are the same as in Example 1.

[0065] The method of dehydration of 1,3-dichloro-2-butene that removes high-boiling point substances is: remove 1,3-dichloro-2-butene that is high-boiling point substances, and use a dehydration distillation tower to remove a small amount of moisture in the material , enter the dehydration rectification tower and add benzene at the same time, heat the benzene water azeotrope to remove the moisture content in the refined 1,3-dichloro-2-butene, then control the temperature in the high boiling rectification tower according to the conditions in Table 5 , pressure and vacuum, dehydration and rectification, remove the moisture in the crude 1,3-dichloro-2-butene, and obtain refined 1,3-dichloro-2-butene containing dichlorobutane ≥ 95% , The total vapor pressure in the rectification tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com