Halogen-free resin glue and film manufactured from same

A halogen resin and glue technology, used in circuit substrate materials, printed circuit components, etc., can solve the problems of poor heat resistance, decrease, and poor substrate toughness, and achieve the effect of increasing flame resistance and improving flame resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

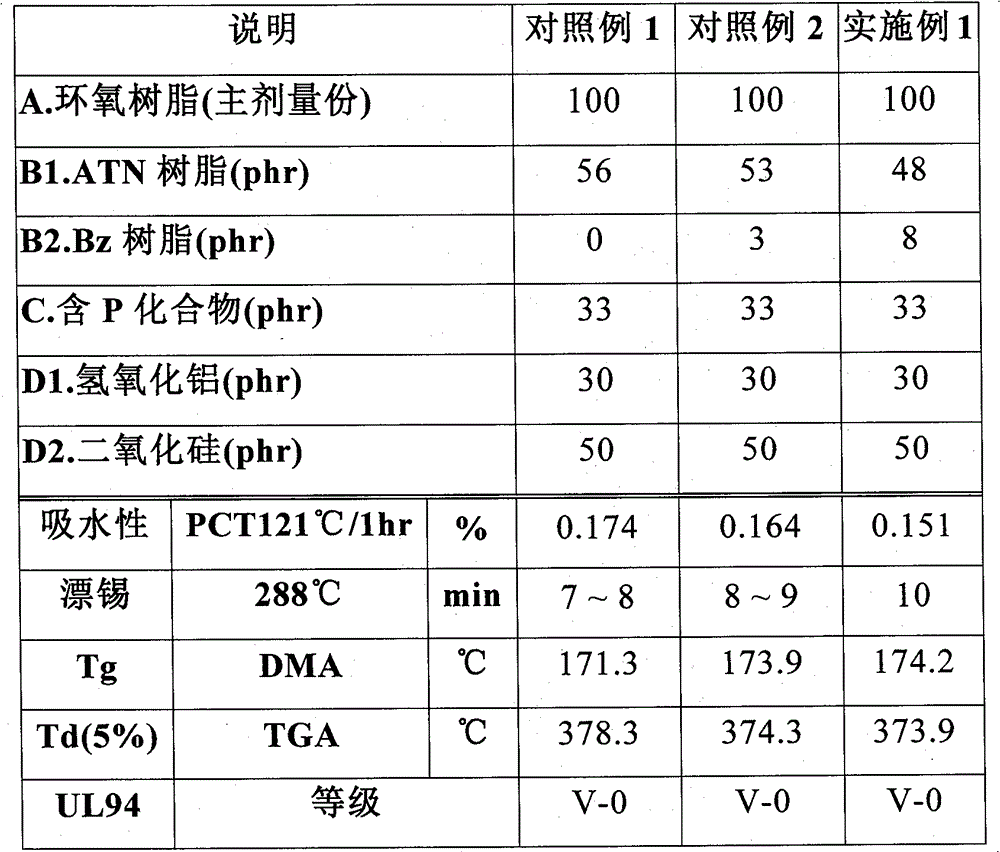

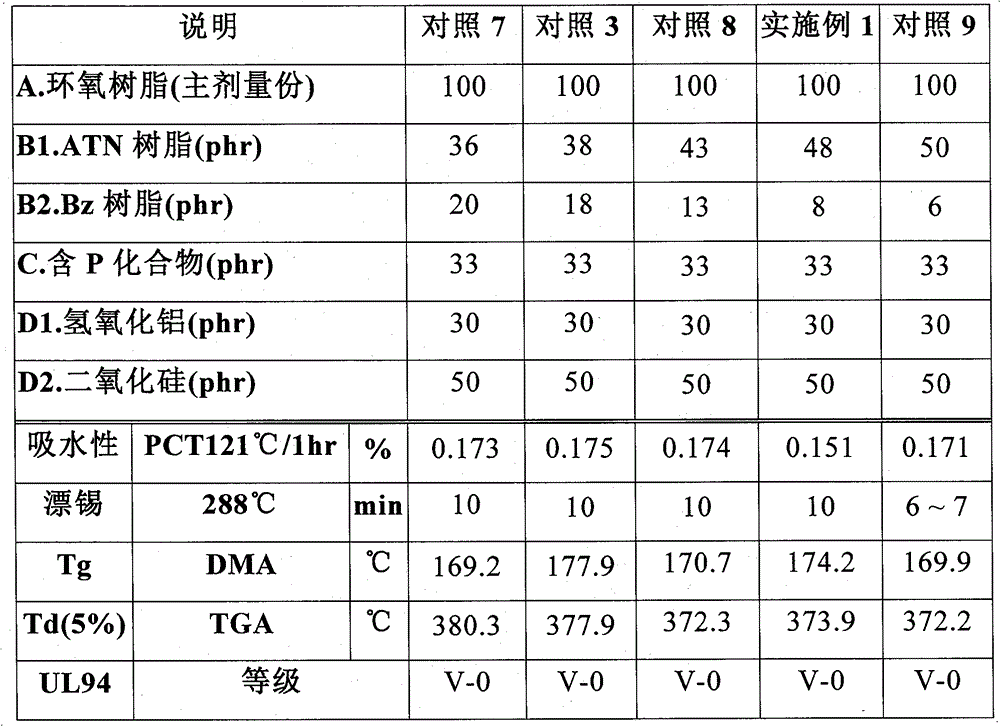

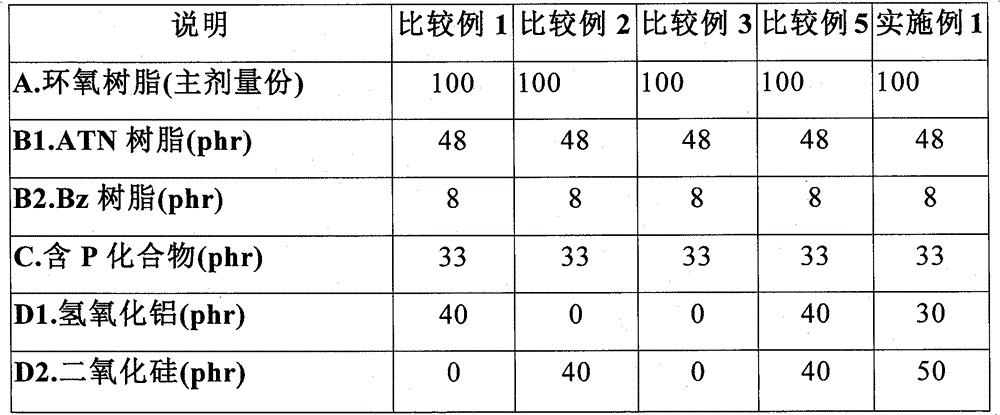

[0012] The present invention provides a composite curing agent, which is added to epoxy resin, so that the glass fiber cloth can be formed into a material with high heat resistance and low hygroscopicity (water absorption) after the dipping step. The film, and the above-mentioned film and copper foil can be used to produce a laminate with heat resistance and moisture absorption characteristics in a hot pressing manner. In addition, the present invention further adds a low-molecular-weight phosphorus-containing compound to improve the heat-resistant and flame-retardant properties of the prepared resin; moreover, the present invention adds an appropriate proportion of fillers to produce a resin with better flame-resistant and flame-resistant properties. Film with thermal properties.

[0013] The composite hardener is mainly formed by mixing the composite hardener with benzoxazine (BZ) resin and aminotriazine novolac (ATN) resin in a predetermined ratio. Aminotriazine phenolic (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com