Construction method for automatic disturbance rejection controller of three-motor synchronous control system

A technology of active disturbance rejection controller and synchronous control, which is applied in the direction of control system, AC motor control, motor speed or torque control, etc. Complicated controller methods, system control performance degradation, etc., to achieve the effect of improving various control performance indicators, simple and easy algorithms, and easy adjustment of parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

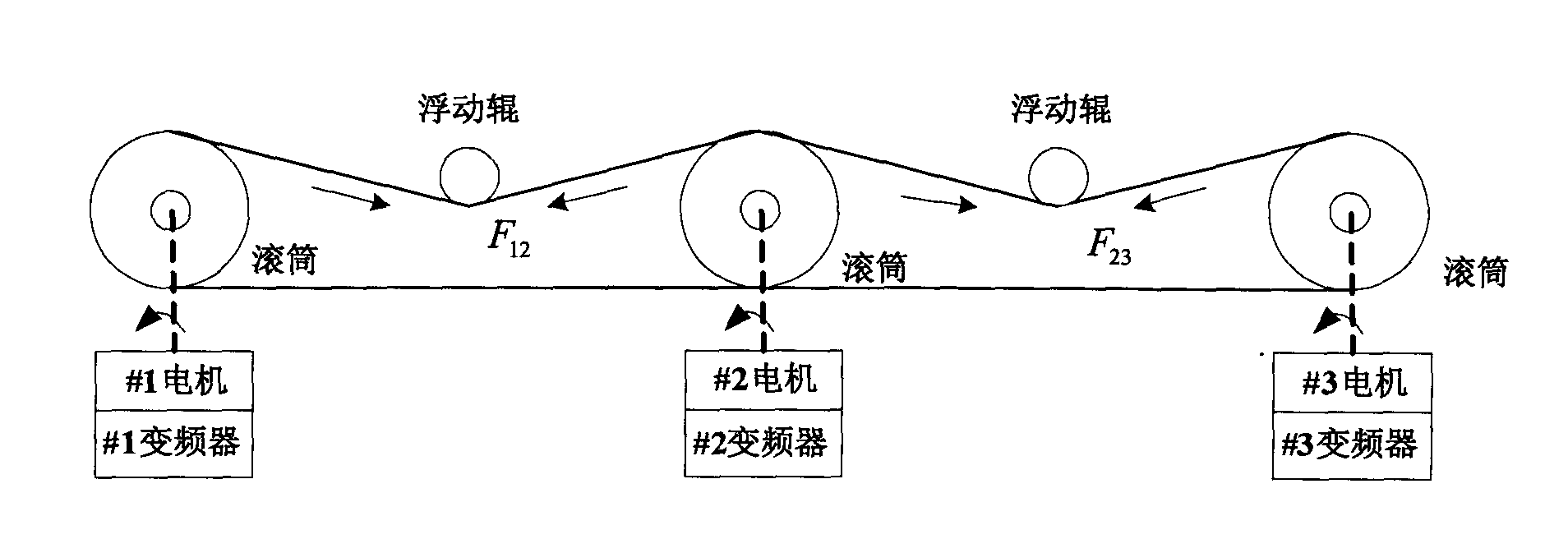

[0017] In the present invention, a three-motor synchronous control system is constructed first, and a control strategy is determined. , figure 1 is a schematic diagram of the simplest setup of a steel strip winding system controlled by three motors, figure 1 The #1 motor is the active motor, and the #2 and #3 motors are the driven motors. Each motor is decelerated by a 1:15 reducer and drives its own roller to run. The three rollers are connected by a tape. #1 motor and #2 motor , #2 motor and #3 motor generate tape tension F through the tension of floating rollers 12 , F 23 . The #1, #2, and #3 inverters respectively drive the corresponding induction motors and drive the common load as a whole to form a synchronous control system for three frequency conversion speed-regulating motors, which is referred to as a three-motor synchronous control system. According to Hooke's law, three Mathematical model formula of motor synchronous control system tension. The tension of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com