Method for preparing Jingan capsules

A technology of capsules and golden sense, which is applied in the direction of capsule delivery, medical preparations containing active ingredients, anti-infective drugs, etc., and can solve the problems of long drying time, low moisture, and the influence of weight difference of golden sense capsule filling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

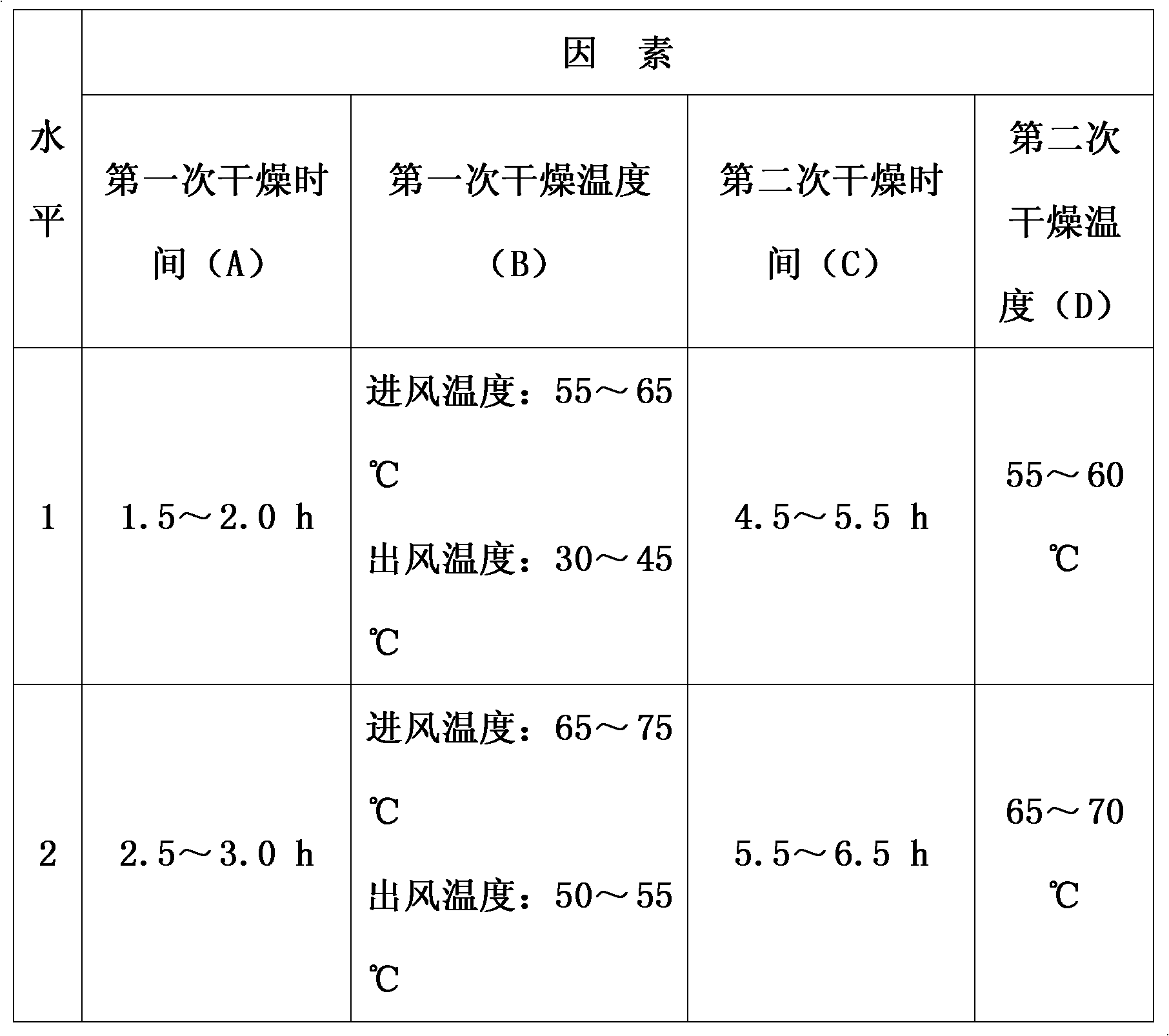

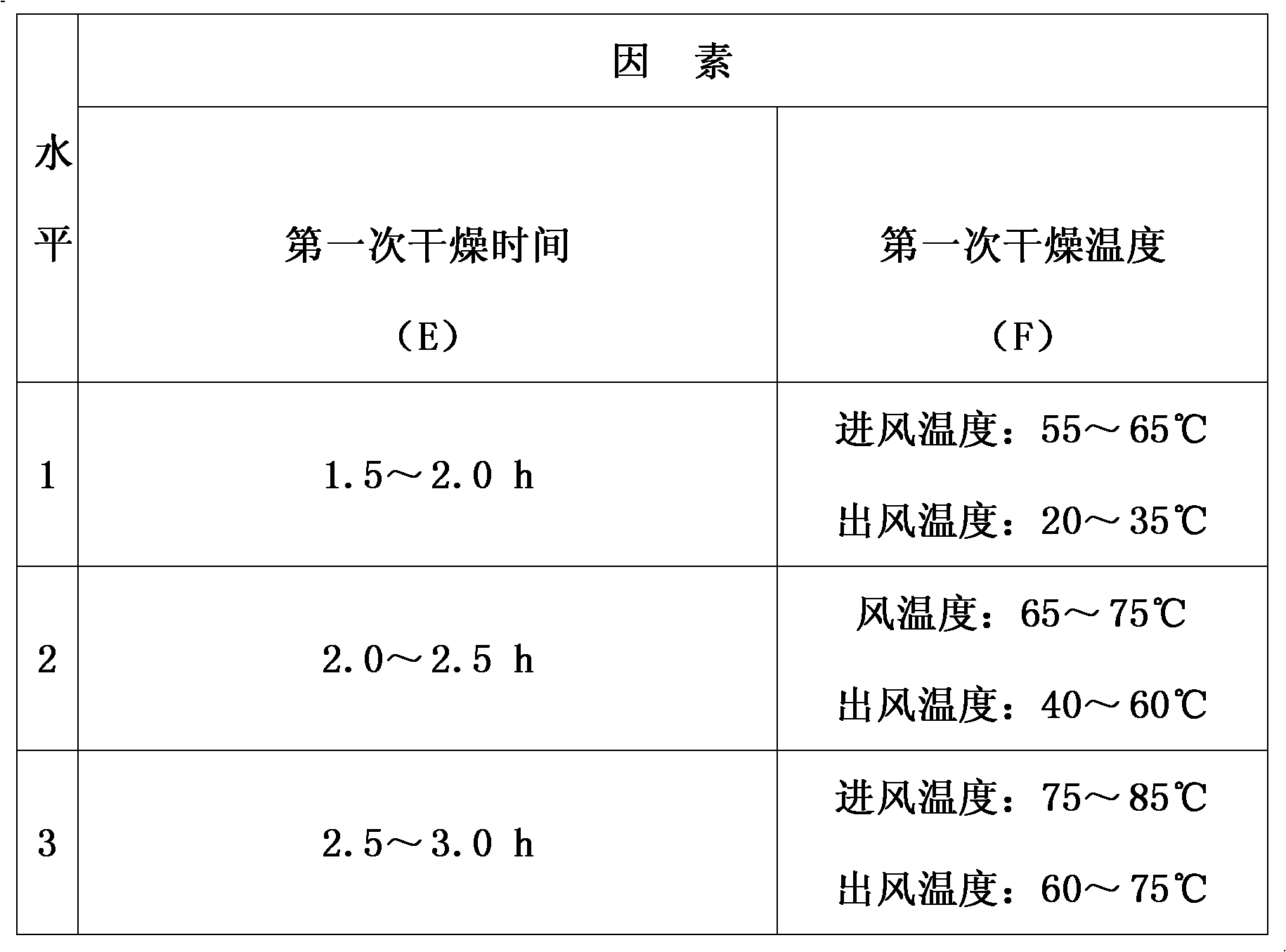

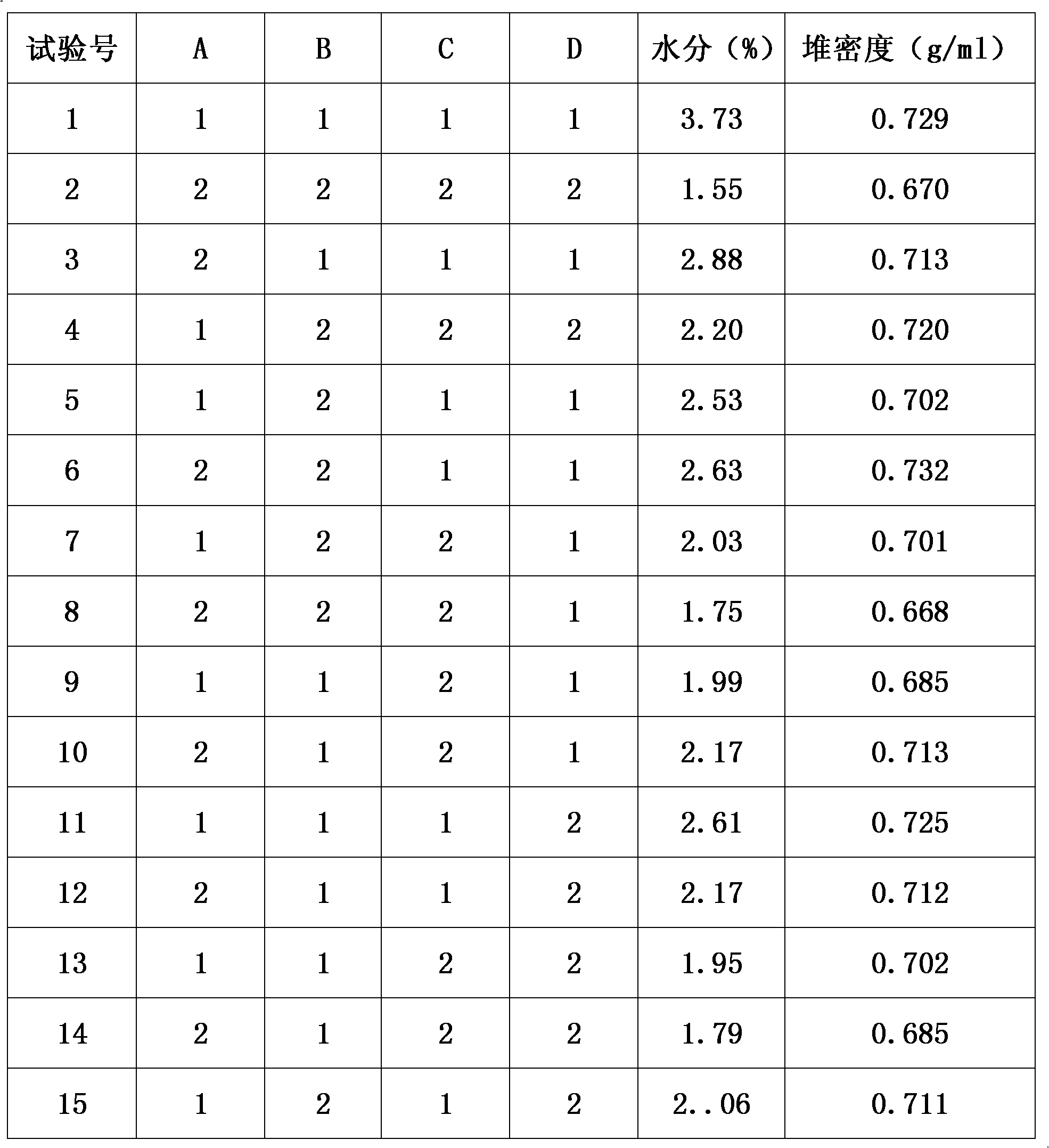

Method used

Image

Examples

Embodiment

[0033] A kind of preparation method of Jingan capsule, according to parts by weight, prepare honeysuckle 250g, Andrographis paniculata 250g, Radix Radix Radix 250g, Dandelion 250g, paracetamol 250g, amantadine hydrochloride 50g, chlorpheniramine maleate 1.0g as Raw material, and prepare according to the following steps;

[0034] a, cut Andrographis paniculata into 12mm segments to get A product;

[0035] b. Cut Radix isatidis into 12mm sections to obtain product B;

[0036] c. Distilling and separating honeysuckle with water steam to obtain product C, and the dregs are used as product C1 for subsequent use;

[0037] d, product A is extracted twice with 85% ethanol, the amount of ethanol added for the first time is 8 times of the amount of medicinal materials, and the time is 2 hours; the amount of ethanol added for the second time is 6 times of the amount of medicinal materials, and the time is 2 hours, combined Decoct twice, recover ethanol, condense into an extract with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com