Production equipment of thin-wall metal cylinder body

A technology for metal cylinders and production equipment, applied in the field of production equipment for thin-walled metal cylinders, which can solve problems affecting the surface flatness of thin-walled metal cylinders, not meeting the surface flatness of printing equipment, poor straightness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

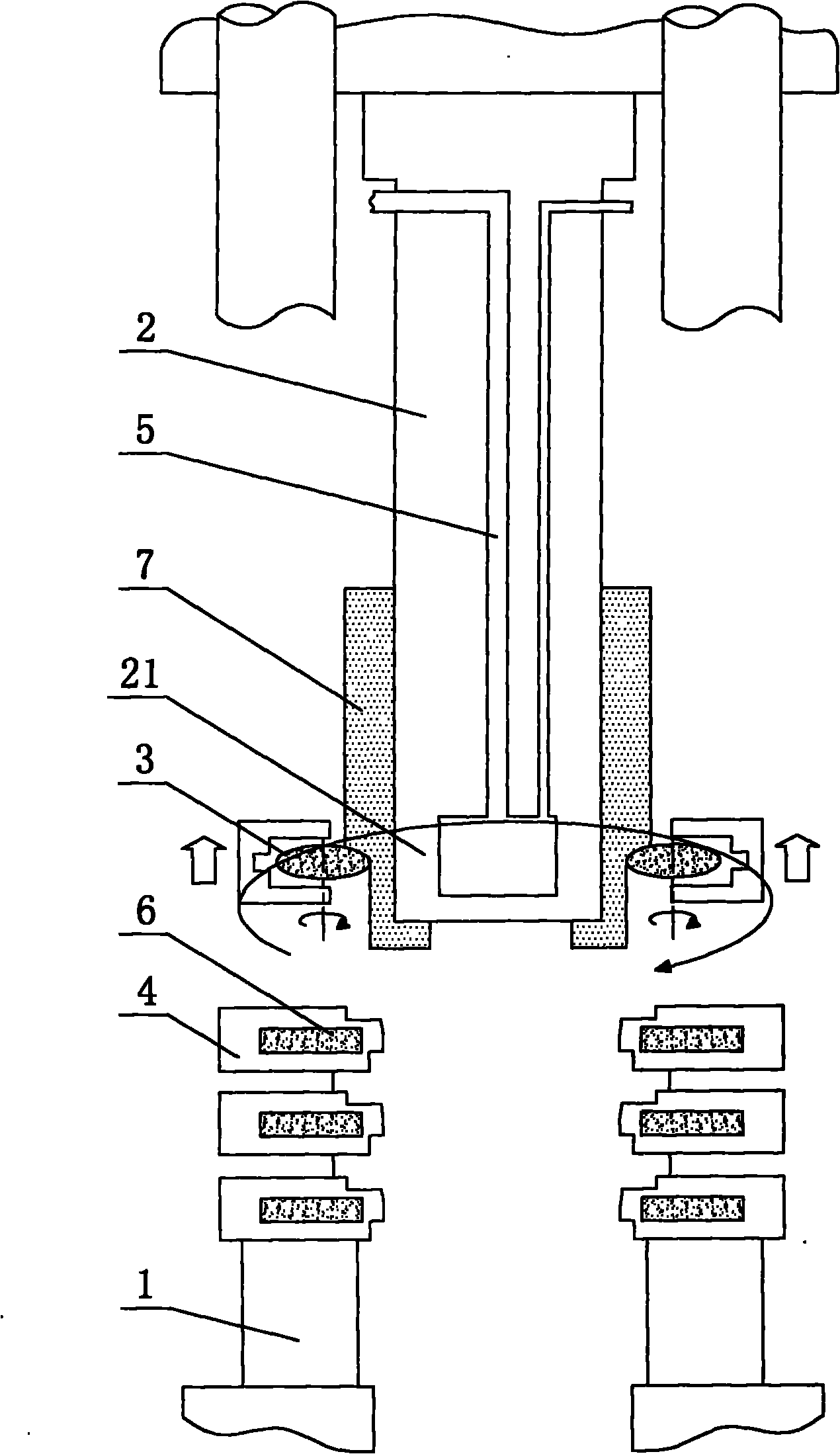

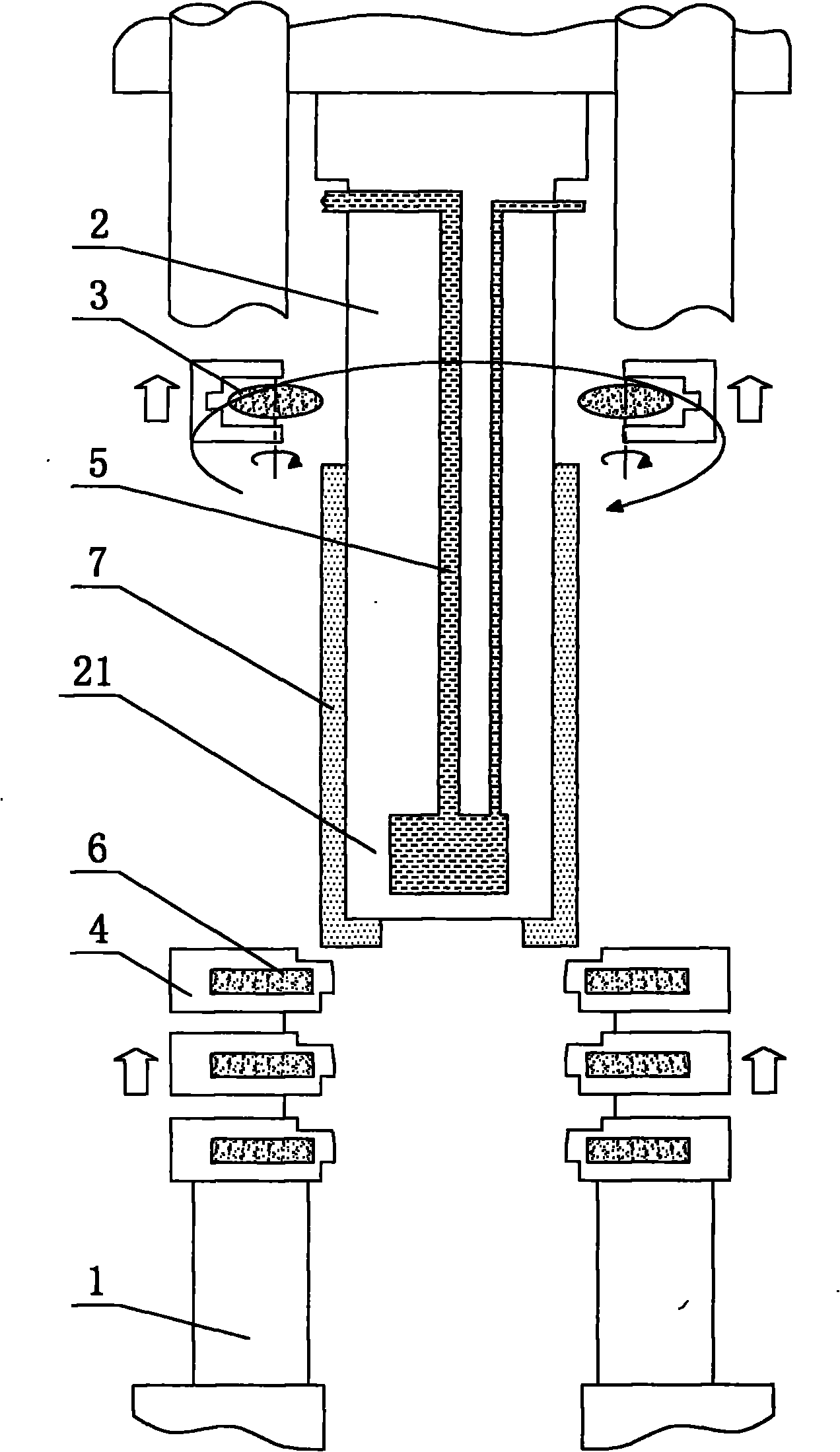

[0028] The production equipment of the thin-walled metal cylinder of the present embodiment includes a vertically placed frame 1, from the upper end to the lower end of the frame 1, a mandrel 2, a spinning part 3 and a punching die 4 are arranged successively, and the spinning The component 3 rotates around the mandrel 2, the spinning part 3 and the punching die 4 can slide up and down along the axis of the mandrel 2, the mandrel 2 is processed with a loop channel 5 extending to the mandrel working end 21, the loop channel 5 Connected with the cooling medium supply device (not shown in the figure), a heating element 6 is arranged in the punching die 4 .

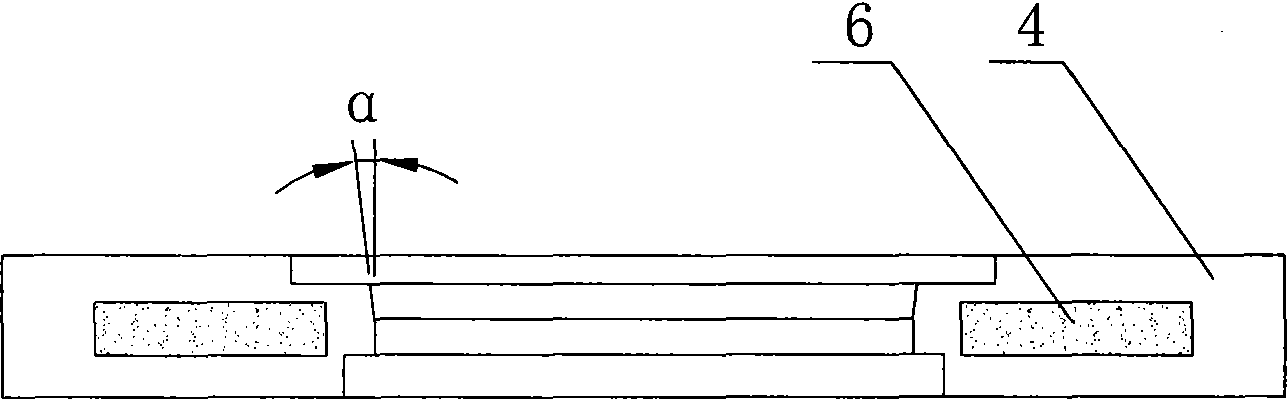

[0029] Such as figure 2 As shown, the die-entry angle α of the punching die 4 is 5 degrees to 9.5 degrees. If the entry angle α is larger than 9.5 degrees, excessive shearing force will be generated on the sheet cylinder and it will be broken. If the mold entry angle α becomes smaller, the extrusion force on the cylinder b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap