Method for inhibiting scales of wet-process phosphoric acid concentration heat exchanger

A wet-process phosphoric acid and heat exchanger technology, applied in the direction of phosphoric acid, phosphorus oxyacid, etc., can solve the problems of uneven mixing of scale inhibitors and phosphoric acid, difficulty in transporting scale inhibitors, etc., achieving low cost, easy installation, and reduced easy clogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] EXAMPLES Taking the wet-process phosphoric acid concentrator of Wengfu (Group) Co., Ltd. Phosphate Fertilizer Factory as an example, the present invention is further described.

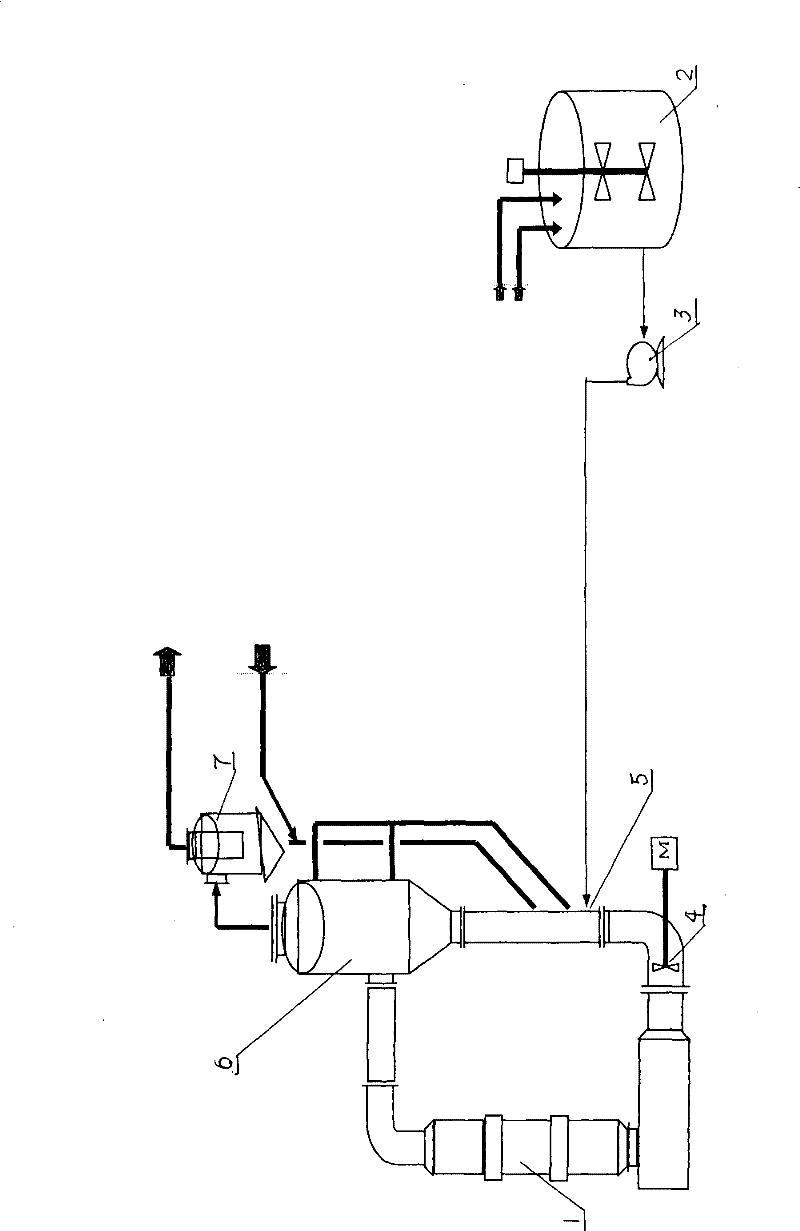

[0016] The company's wet-process phosphoric acid concentration plant includes a flash evaporator 6, a heat exchanger 1 and an axial flow pump 4. Originally, the gear pump was used to add the antiscalant to the heat exchanger, and the adding location was located at the 4 inlet of the concentrated axial flow pump. Due to the high viscosity of the antiscalant, the large resistance of the pipeline, the difficulty of transporting the antiscalant, the serious wear of the gear pump, and the part of the short circuit after the antiscalant enters the concentration system is taken away by the product acid, the effect of antiscaling is not obvious. Adopt the method of the present invention now, be provided with preparation tank 2 and plunger pump 3, select amino trimethylene phosphonic acid as antiscalant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com