Vertical distribution hidden type stirring station for subway construction

A concealed mixing station technology, which is applied in the field of vertically distributed concealed mixing stations for subway construction, can solve the problems of long air transmission distance, constraints on the production capacity, popularization rate and regionality of concrete mixing stations, and large floor area. Achieve the effect of saving land use cost, improving land use efficiency and reducing land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

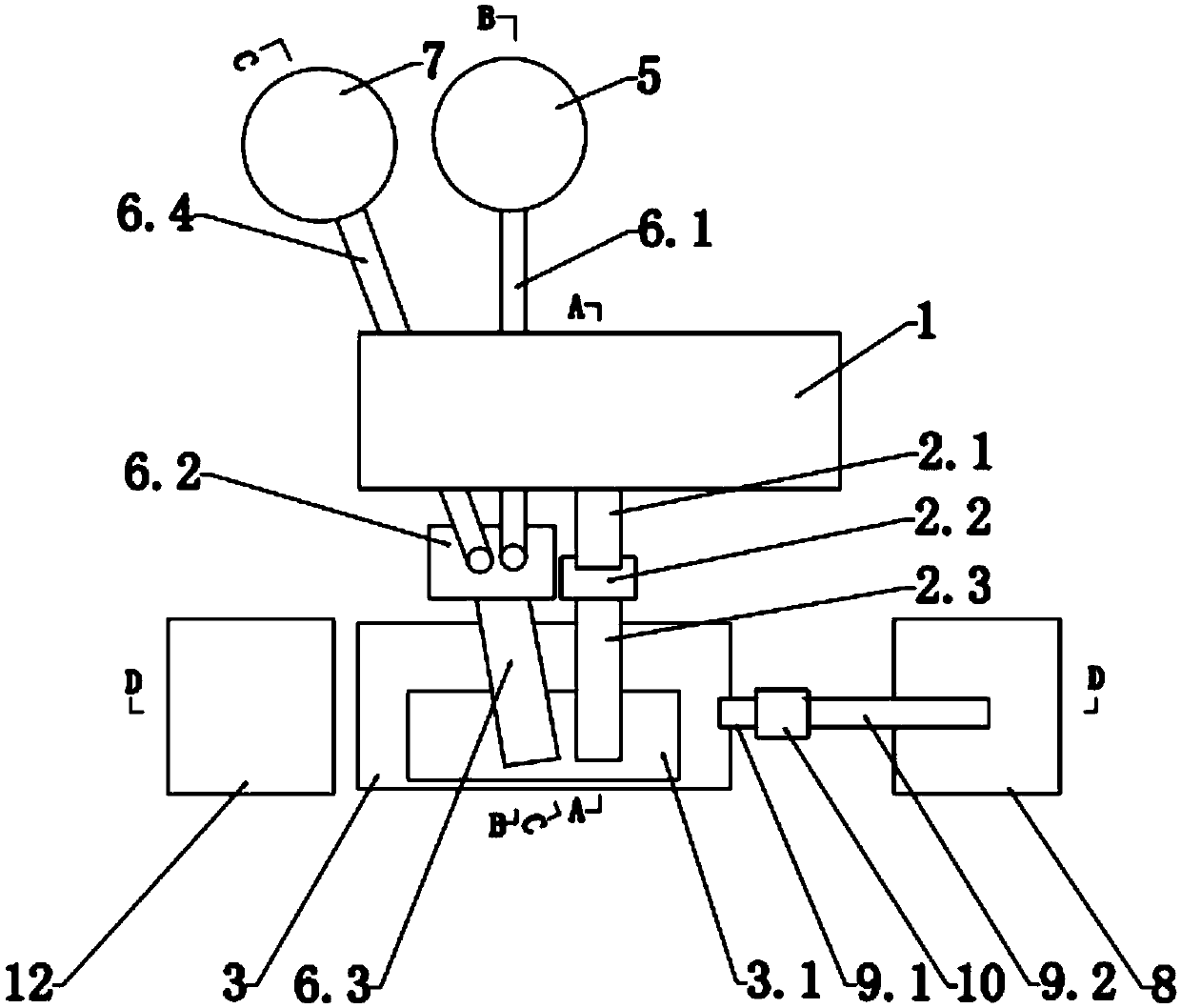

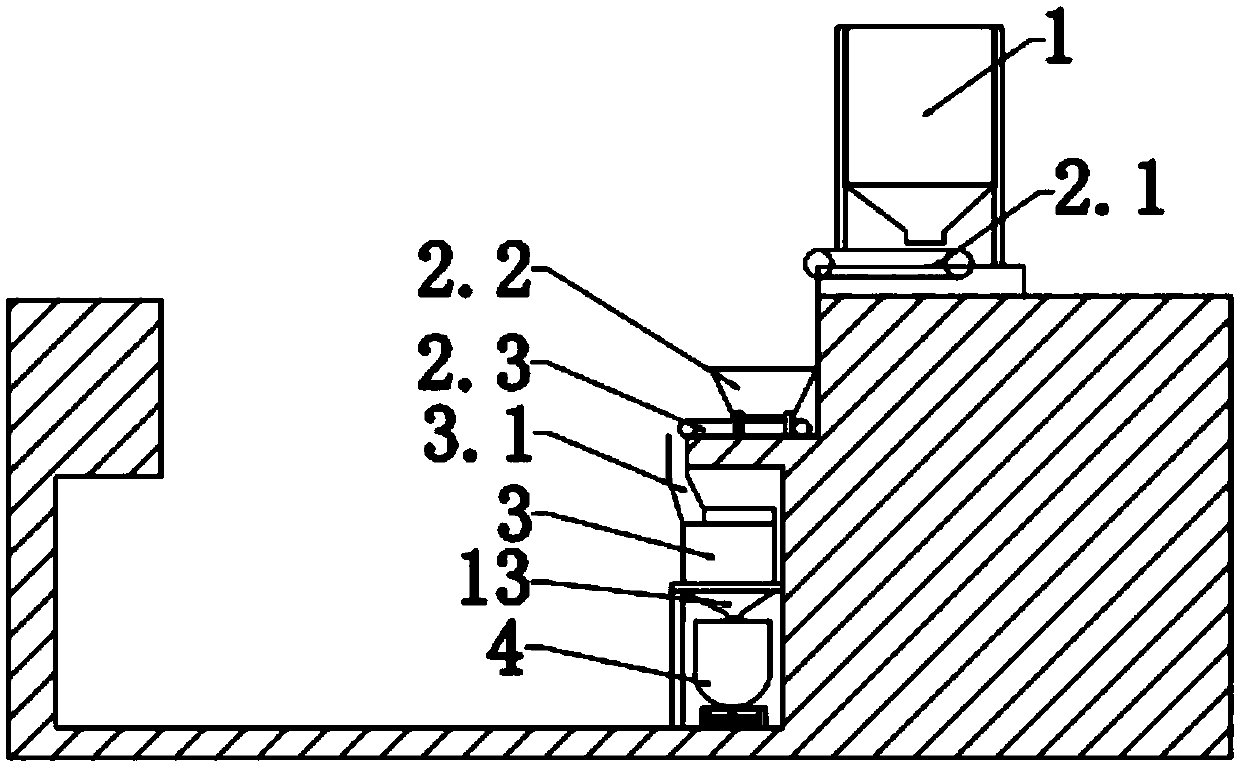

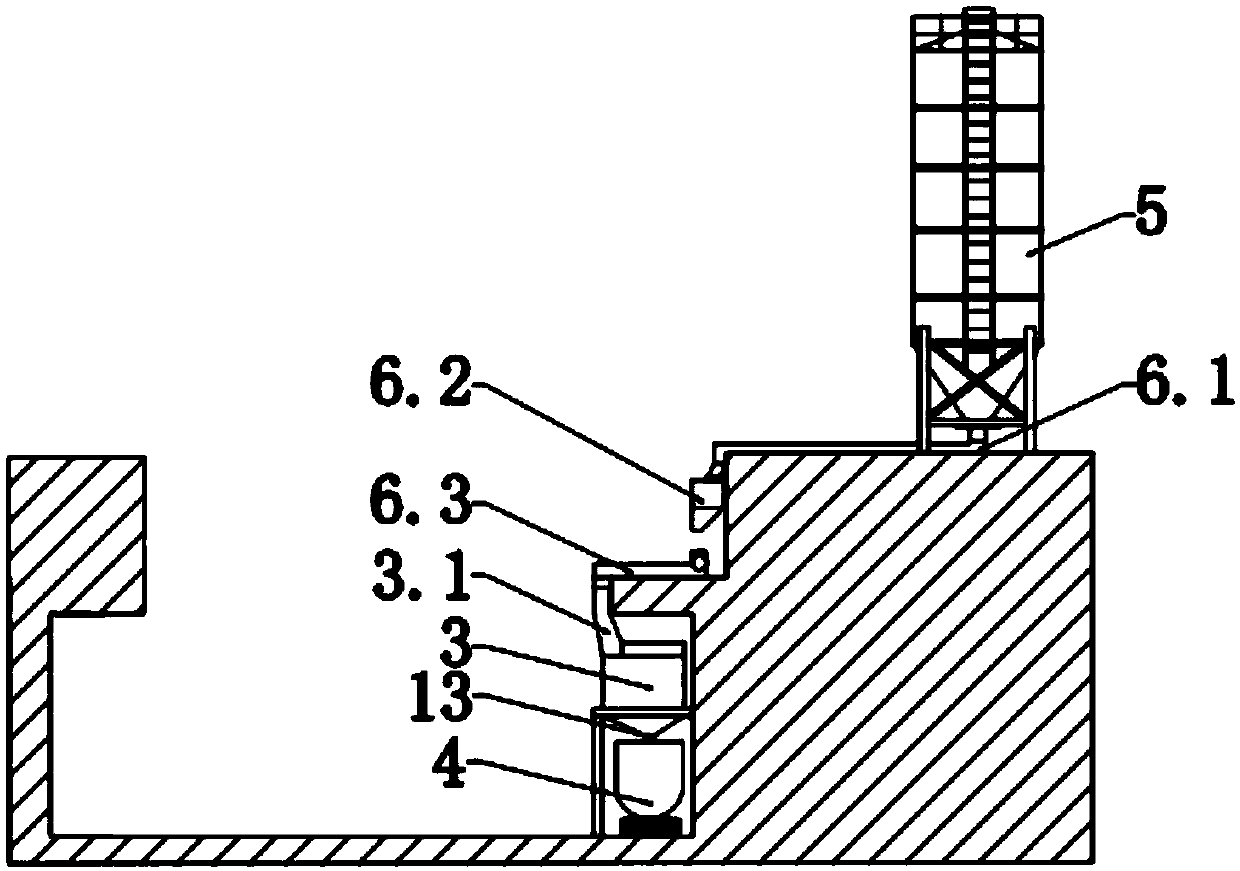

[0025] As shown in the figure, a vertically distributed concealed mixing station for subway construction, including a mixing system, a powder system, and an aggregate system;

[0026] The mixing system is located below the ground, and the mixing system includes a mixer 3. A discharge device 13 is provided below the mixer 3. A mortar truck 4 is provided below the discharge device 13. A water tank 8 is provided on one side of the mortar truck 4, and a water tank 8 It communicates with the mixer 3 through pipelines, wherein the unloading device 13 is a hopper, and the pipelines include a first pipeline 9.1 and a second pipeline 9.2. One end of the second pipeline 9.2 is connected to the water tank 8, and the second pipeline 9.2 The other end of the water scale is connected with a water scale 10, and the bottom end of the water scale 10 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com