A purification and concentration process for waste dilute sulfuric acid

A dilute sulfuric acid, process technology, applied in the direction of sulfur compounds, sulfur trioxide/sulfuric acid, inorganic chemistry, etc., can solve the difficult to achieve the purpose and requirements of enterprise recycling, waste acid cannot be recycled and reused, and the value of waste acid is limited and other problems, to achieve the effect of reducing equipment space layout, reducing equipment easy to block, and low cost treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

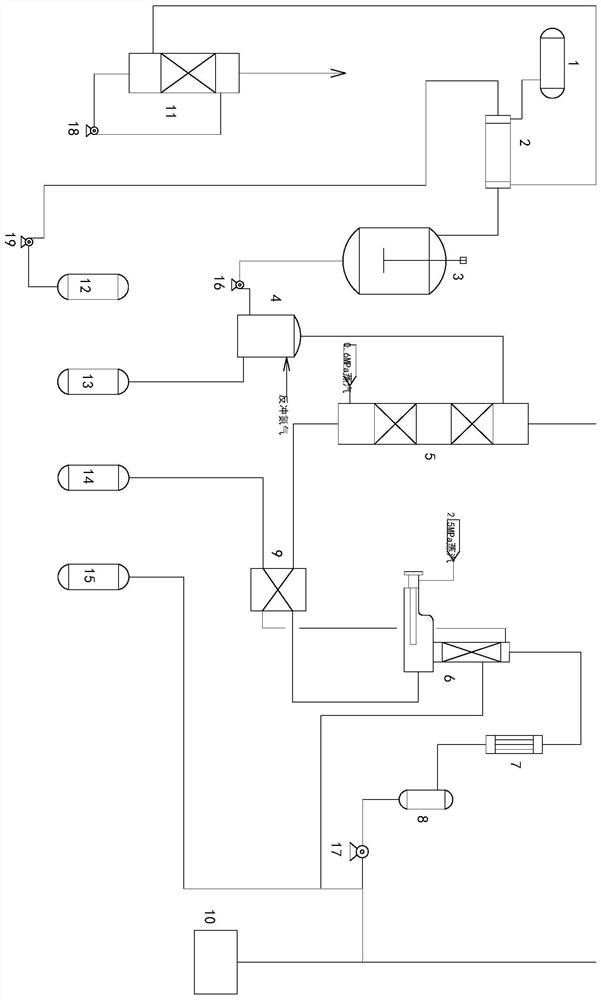

[0034] The oxidant tank 1 is communicated with the inlet of the mixer 2 through configuring 20% hydrogen peroxide, and the top of the mixer 2 is communicated with the tail gas absorption tower 11 for tail gas treatment. achieve safe discharge.

Embodiment 2

[0036] The bottom of the mixer 2 is connected with the stirring reactor 3, and the stirring of the stirring reactor 3 can reduce the reaction time, accelerate the oxidation of organic components of the acid, and achieve the purpose of completely decolorizing the waste acid.

Embodiment 3

[0038] The waste acid impurity filtration system in the process includes two sets of filtration feed volume pump 16 and membrane filtration equipment 4. The membrane adopts PTFE material to enter and exit from the outside. Feed volume pump 16 communicates with membrane filtration equipment 4 to filter acid impurities. The top of membrane filtration equipment 4 communicates with stripping tower 5, the bottom of membrane filtration equipment 4 communicates with impurity collection tank 13, and the upper part of membrane filtration equipment 4 is provided with backwash structure, impurities enter the collection tank 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com