Early strength grouting material

A grouting material and aggregate technology, which is applied in the fields of engineering materials and grouting materials, can solve the problems of difficult self-leveling, low early strength, setting and hardening time greater than 5 hours, etc., and achieves the effect of improving construction efficiency and strong cohesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

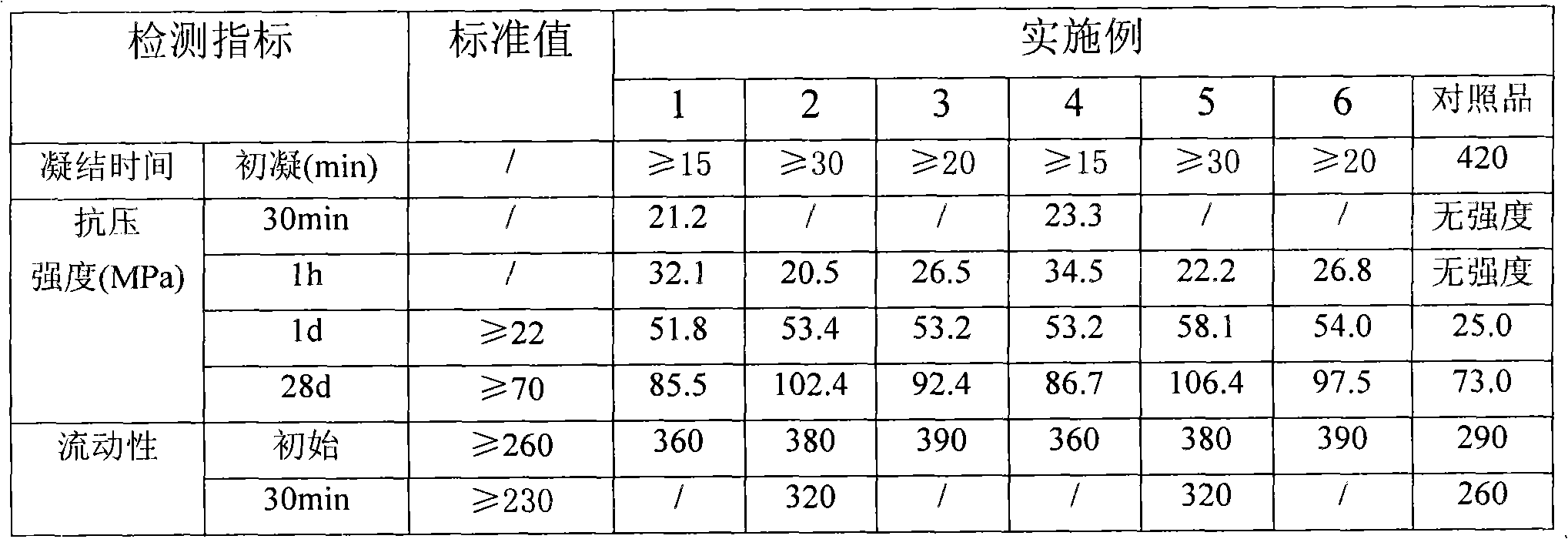

Examples

Embodiment 1

[0036] Select 50 kg of sulfur-aluminum cement, 46 kg of sand (G1, G2, G3 are mixed according to 30, 60, and 10 parts), 4 kg of natural anhydrite powder, 0.3 kg of water reducing agent sulfonated melamine formaldehyde resin, coagulant lithium hydroxide 0.07 kg, 0.02 kg of retarder citric acid, 0.02 kg of water retaining agent methyl cellulose. First, mix 5 kg of cement with water reducing agent, coagulant accelerator and coagulant retarder evenly with a small mixer, then put all the materials into the mixer and mix them evenly before packing them into bags. Add 16% water during repairing construction, and use it after stirring for 3 minutes with a forced mixer.

Embodiment 2

[0038]Select 44.5 kg of sulfur-aluminum cement, 50 kg of sand (G1, G2, G3 are mixed according to 30, 50, and 20 parts), 5.5 kg of natural mixed gypsum powder, 0.6 kg of polycarboxylic acid with a gas content of less than 3% in the water reducing agent, coagulation accelerator Lithium carbonate 0.05 kg, retarder boric acid 0.03 kg, water retention agent hydroxypropyl methylcellulose 0.01 kg. First, mix 5 kg of cement with water reducing agent, coagulant accelerator, coagulant retarder and water retaining agent with a small mixer, then put all the materials into the mixer and mix them evenly before packing them into bags. When grouting bridge bearings, add 16% water and stir with a forced mixer for 3 minutes before use.

Embodiment 3

[0040] Select 40 kg of sulfur-aluminum cement, 55 kg of sand (G1, G2, G3 are mixed according to 27, 55, and 18 parts), 5 kg of dihydrate gypsum powder, water reducing agent (sulfonated melamine formaldehyde resin and polystyrene with a gas content of less than 3%) Carboxylic acid superplasticizer is compounded at 1: 1, and other ratios are also used for compounding) 0.4 kg, coagulant lithium carbonate 0.06 kg, retarder boric acid 0.02 kg, water retaining agent lignocellulose 0.01. First, mix 5 kg of cement with water reducing agent, coagulant accelerator, coagulant retarder and water retaining agent with a small mixer, then put all the materials into the mixer and mix them evenly before packing them into bags. During the grouting construction of highway and bridge joint joints, add 16% water, stir with a forced mixer for 3 minutes, and then use it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com