Oil-absorbing polyurethane foam material

A polyurethane foam and oil-absorbing technology, applied in the field of oil-absorbing polyurethane foam materials, can solve the problems of low open cell rate, cannot be used repeatedly, limited oil absorption efficiency, etc., and achieves high comprehensive efficiency, strong oil capacity, and high open cell rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1 is a comparative example, adopts the formula of open-cell rigid polyurethane foam, and formula table is as follows:

[0063] Component one:

[0064] Isocyanate PM200 152 parts

[0065] Component two:

[0066] Ethylenediamine polyether polyol KP043 (hydroxyl value 770±30KOH mg / g) 15 parts

[0067] Polyoxypropylene diol KP046 (hydroxyl value 100±10KOH mg / g) 15 parts

[0068] Sucrose polyether polyol KP041 (hydroxyl value 430±20KOH mg / g) 50 parts

[0069] Sorbitol / glycerol polyether polyol KP045 (hydroxyl value 500±20KOH mg / g) 20 parts

[0070] 3 parts triethanolamine

[0071] Surfactant B8462 2 parts

[0072] N,N-Dimethylcyclohexylamine 3 parts

[0073] 3.5 parts of water

[0074] Foaming agent 141b 40 parts

[0075] Mix the ingredients in the second component of the formula table evenly to make the second component.

[0076] Mix component 1 and component 2 according to the formula ratio, mix and stir on an electric mixer for 8 seconds, pour it into...

Embodiment 2

[0081] Embodiment 2 is comparative example, adopts soft polyurethane foam formula, and formula table is as follows:

[0082] Component one:

[0083] Isocyanate Voranate T-80 122 parts

[0084] Component two:

[0085] Aliphatic polyester polyol KP056 (hydroxyl value 110±5KOH mg / g) 100 parts

[0086] Surfactant DC5526 2 parts

[0087] Catalyst Dabco2039 2 parts

[0088] 8 parts water

[0089] Tris (2-chloropropyl) phosphate 10 parts

[0090] Mix the ingredients in the second component of the formula table evenly to make the second component.

[0091] Mix component 1 and component 2 according to the formula ratio, mix and stir on an electric mixer for 8 seconds, pour it into an open mold, let it foam freely, and the material foaming molding time is 5 minutes. After the foam is fully matured, prepare a sample and measure its performance.

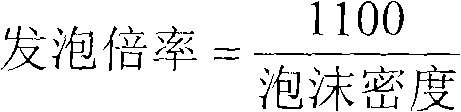

[0092] The prepared flexible polyurethane foam material density of embodiment 2 is 21.2kg / m 3 , the expansion ratio is 51.9 times, the...

Embodiment 3

[0094] Embodiment 3 is the embodiment of the low-density high porosity semi-rigid polyurethane foam material of the present invention, adopts polyester polyol to improve the lipophilicity of foam material, formula table is as follows:

[0095] Component one:

[0096] Isocyanate PM200 142 parts

[0097] Component two:

[0098] Highly active polyoxypropylene triol KP047 (hydroxyl value 35±3KOH mg / g) 45 parts

[0099] Polyoxypropylene diol KP046 (hydroxyl value 100±10KOH mg / g) 50 parts

[0100] Aliphatic polyester polyol KP056 (hydroxyl value 110±5KOH mg / g) 5 parts

[0101] 3 parts glycerin

[0102] Surfactant L580 2 parts

[0103] N,N-Dimethylcyclohexylamine 2 parts

[0104] 25 parts of water

[0105] Tris (2-chloropropyl) phosphate 10 parts

[0106] Mix the ingredients in component two in the formula table evenly to make component two.

[0107] Mix component 1 and component 2 according to the formula ratio, mix and stir on an electric mixer for 8 seconds, pour it into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com