Manufacturing method of yttrium aluminum garnet (YAG) fluorescent powder for white light LED

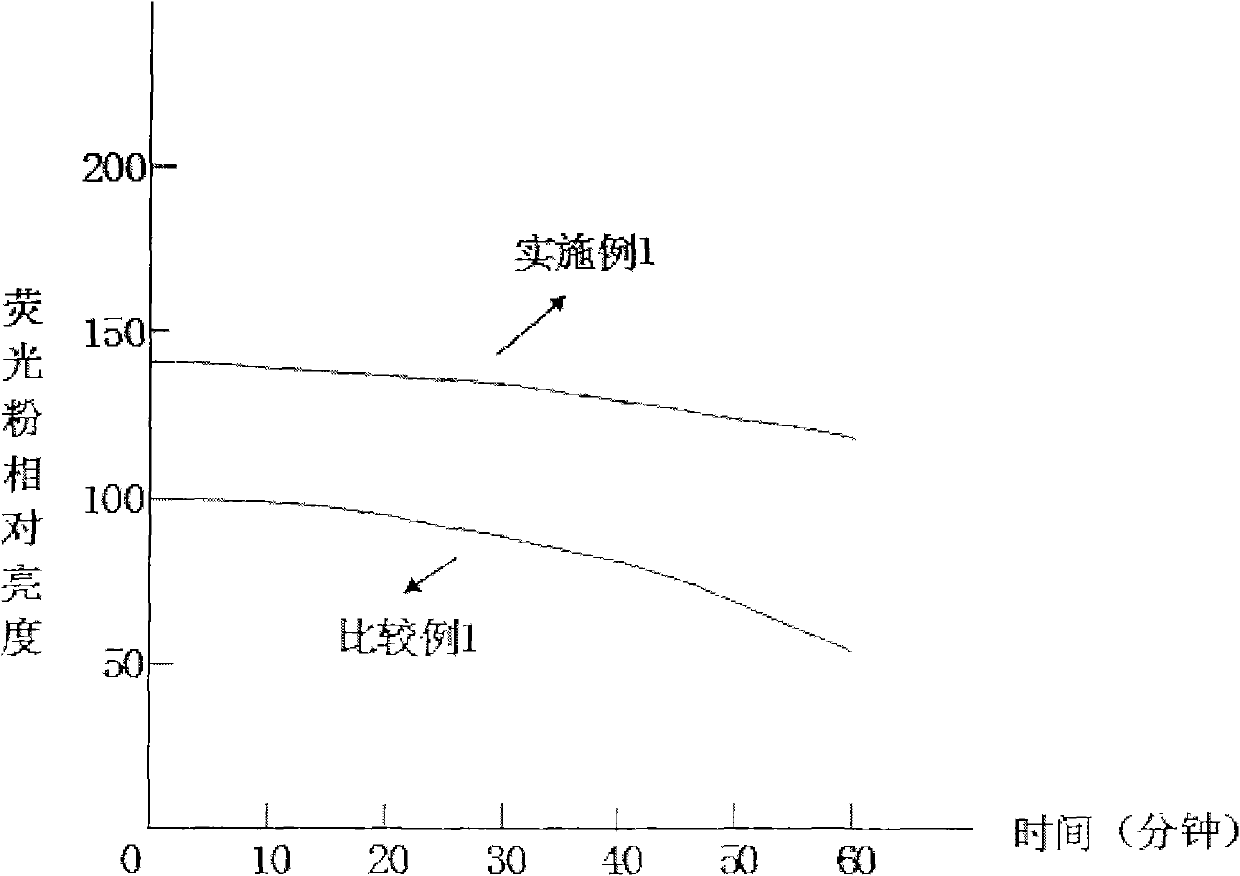

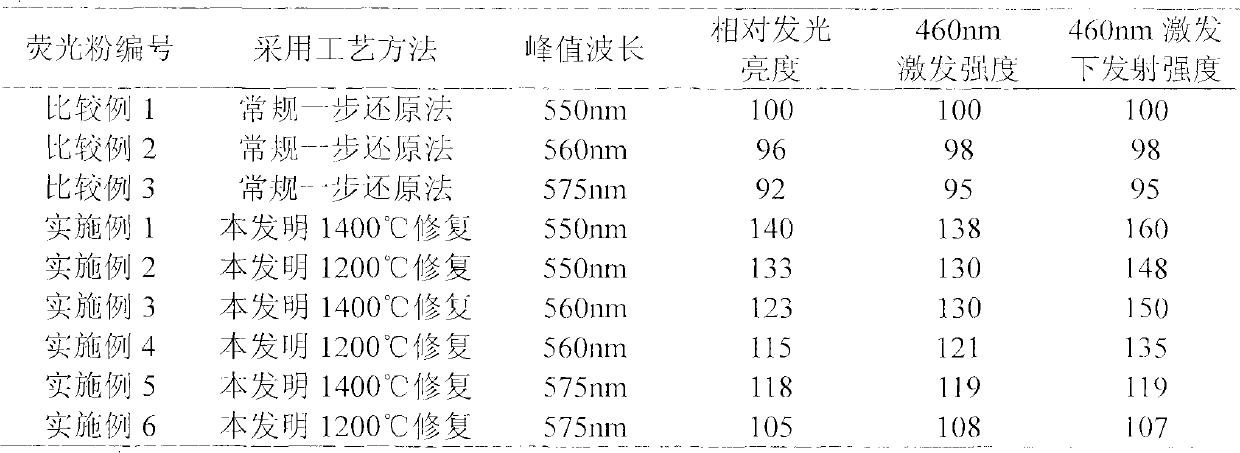

A manufacturing method and phosphor technology, which are applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of affecting the service life of firing equipment, poor luminescence performance of phosphors, and increased production costs, and achieve emission intensity and brightness luminous intensity. The effect of high, low light decay, and increased absorption intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The composition of YAG phosphor is Y 2.9 al 5.0 o 12 : Ce 0.1

[0025] 1) Mixing: Accurately weigh 177.344g Y 2 o 3 , 138.00g Al 2 o 3 , 9.308g CeO 2 , 16.00g flux BaF 2 , put into the mixer and mix for 24 hours;

[0026] 2) High-temperature pre-firing: put the mixed material into a crucible, pack it tightly and solidly, and heat it in normal pressure air for 4 hours at 1600°C, then pre-fire;

[0027] 3) High-temperature reduction: coarsely crush the pre-fired material, pass through a 100-mesh sieve, then finely crush it, pass through a 150-mesh sieve,

[0028] Loosely loaded into the crucible, using H 2 :N 2 = 7:3 reducing atmosphere, 1550 ° C for 2 hours;

[0029] 4) Break the high-temperature reduced material, sieve it with 150 mesh, and ball mill it. During ball milling, mix the material with glass marbles with a diameter of 2 to 5 mm and pure water according to the mass ratio of powder: ball: pure water = 1:2:3 , ball mill for 1 hour, remove the glass...

Embodiment 2

[0035] The composition of the YAG fluorescent powder and the types of raw materials are exactly the same as in Example 1, and the reaction steps 1) to 6) and step 8) are exactly the same as in Example 1, except that in step 7), the reduction temperature is 1200°C.

Embodiment 3

[0042] The composition of YAG phosphor is Y 2.81 Gd 0.07 al 5.0 o 12 : Ce 0.12

[0043] 1) Mixing: Accurately weigh 168.104g Y 2 o 3 , 135.00g Al 2 o 3 , 6.718g Gd 2 o 3 , 10.927gCeO 2 , 16.00g flux BaF 2 , put into the mixer and mix for 24 hours;

[0044] 2) High-temperature pre-firing: put the mixed material into a crucible, pack it tightly and solidly, keep it warm in normal pressure air for 5 hours at 1550°C, and pre-fire;

[0045] 3) High-temperature reduction: roughly crush the pre-fired material, pass through a 100-mesh sieve, then finely crush it, pass through a 150-mesh sieve, loosely put it into a crucible, and use H 2 :N 2 = 1:1 reducing atmosphere, 1450°C heat preservation for 5 hours;

[0046] 4) Break the high-temperature reduced material, sieve it through a 150-mesh sieve, and ball mill it. During ball milling, mix the material with glass marbles with a diameter of 2 to 5 mm and pure water according to the mass ratio of powder:ball:pure water=1:1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com