ZnO/Fe/Fe3C/C (zinc oxide/iron/iron carbide/carbon) composite electromagnetic wave absorbent and preparation method thereof

A technology of composite electromagnetic and electromagnetic wave absorption, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of ternary and multi-element composite material performance research, complex preparation process, and ambiguous relationship, etc., to achieve excellent wave absorption The effect of performance, simple process, and absorption frequency bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] ZnO / Fe / Fe of the present invention 3 The preparation method of C / C porous composite electromagnetic wave absorbing agent comprises the following steps:

[0031] Step 1: Add 2.16g iron acetylacetonate, 1.67g zinc nitrate, 0.34g terephthalic acid and 7.2g PVP (K29-K32) to 300mL N,N-dimethylformamide and 180mL ethanol mixed solvent, completely dissolve Afterwards, reflux at 100°C for 6h; the product was washed by centrifugation and dried to obtain the precursor Fe III -MOF-5;

[0032] Step 2: Precursor powder in N 2 In the atmosphere, the temperature was raised to 600°C at a rate of 5°C / min and kept for 2 hours. After natural cooling, ZnO / Fe / Fe 3 C / C composite material, marked as ZFC-600.

Embodiment 2

[0034] ZnO / Fe / Fe of the present invention 3 The preparation method of C / C porous composite electromagnetic wave absorbing agent comprises the following steps:

[0035] Step 1: Add 2.16g iron acetylacetonate, 1.67g zinc nitrate, 0.34g terephthalic acid and 7.2g PVP (K29-K32) to 300mL N, N-dimethylformamide and 180mL ethanol mixed solvent, after completely dissolving , refluxed at 100°C for 6h; the product was washed by centrifugation and dried to obtain the precursor Fe III -MOF-5;

[0036] Step 2: Put the precursor powder in N 2 In the atmosphere, the temperature was raised to 650°C at a rate of 5°C / min and kept for 2 hours. After natural cooling, ZnO / Fe / Fe 3 C / C composite material, labeled ZFC-650.

Embodiment 3

[0038] ZnO / Fe / Fe of the present invention 3 The preparation method of C / C porous composite electromagnetic wave absorbing agent comprises the following steps:

[0039]Step 1: Add 2.16g iron acetylacetonate, 1.67g zinc nitrate, 0.34g terephthalic acid and 7.2g PVP (K29-K32) to 300mL N, N-dimethylformamide and 180mL ethanol mixed solvent, after completely dissolving , refluxed at 100°C for 6h; the product was washed by centrifugation and dried to obtain the precursor Fe III -MOF-5;

[0040] Step 2: Precursor powder in N 2 In the atmosphere, the temperature was raised to 700°C at a rate of 5°C / min and kept for 2 hours. After natural cooling, ZnO / Fe / Fe was obtained. 3 C / C composite material, labeled ZFC-700.

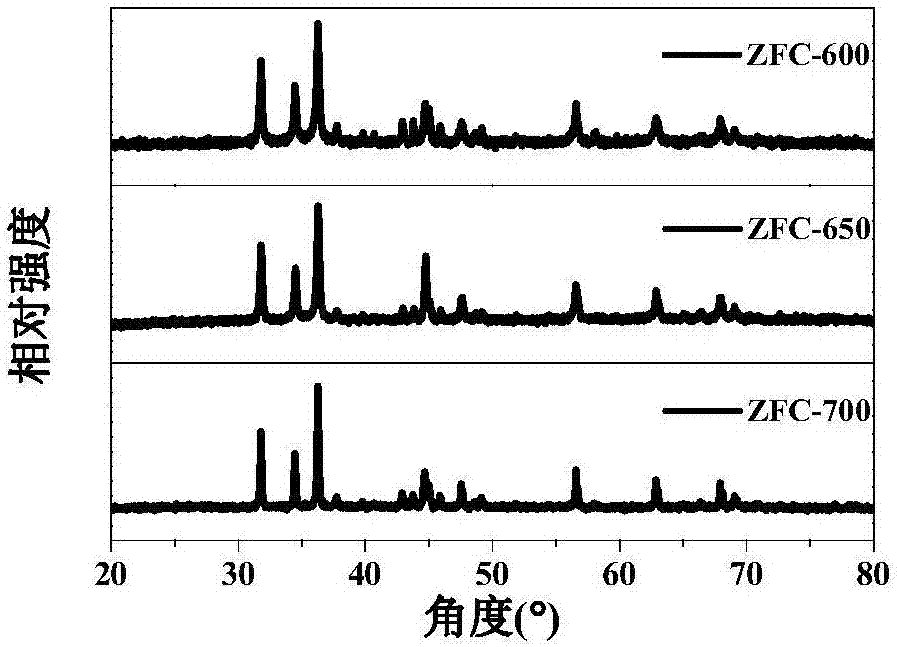

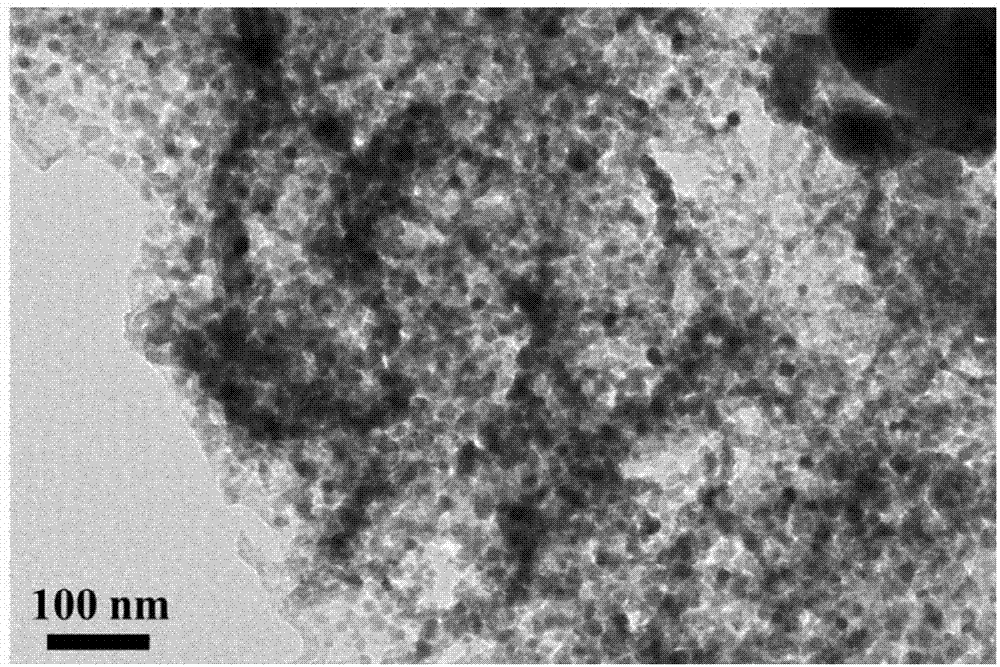

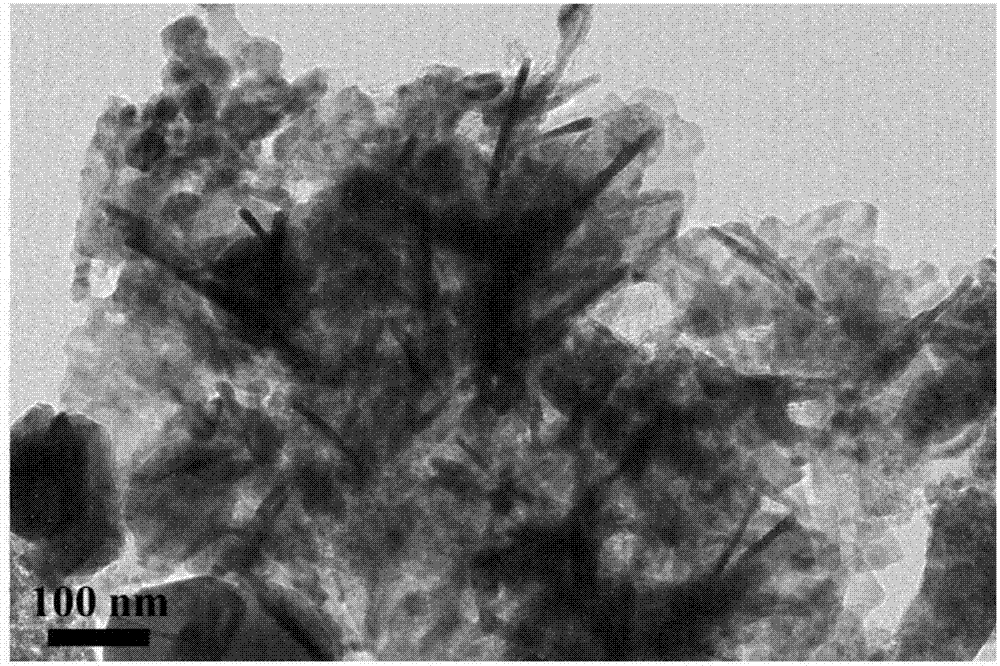

[0041] figure 1 For the X-ray diffraction spectrum of the composite absorbing material that the embodiment of the present invention 1,2,3 makes, from figure 1 It can be seen that the composite absorbing material only contains ZnO, Fe and Fe 3 The characteristic peak o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com