Method and device for producing biological butanol by continuous extraction and fermentation

A bio-butanol and extraction technology, applied in fermentation, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as excessive waste water, waste of raw materials, unfavorable energy saving and emission reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

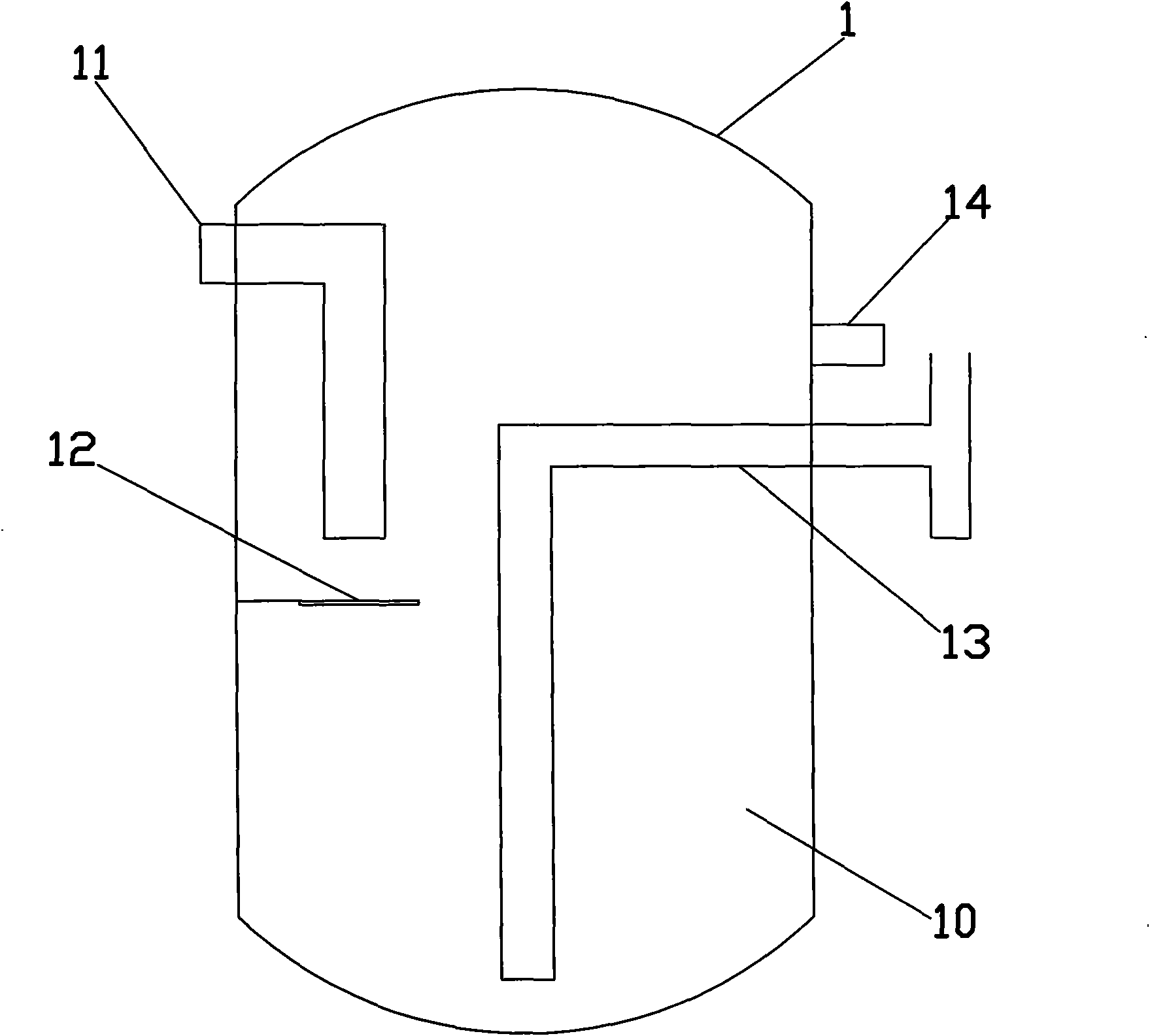

[0030] Such as figure 1 The shown single-unit extraction and separation equipment 1 includes a container 10, the upper part of the container 10 is provided with a feed pipe 11, a heavy phase separation pipe 13, and a light phase separation pipe 14, and the bottom of the outlet of the feed pipe 11 is provided with a blocking material. The plate 12 is used for buffering materials, the inlet of the heavy phase separation pipe 13 is located at the lower part of the container 10, and the heights of the feed pipe 11, the light phase separation pipe 14, and the heavy phase separation pipe 13 are successively lowered.

Embodiment 2

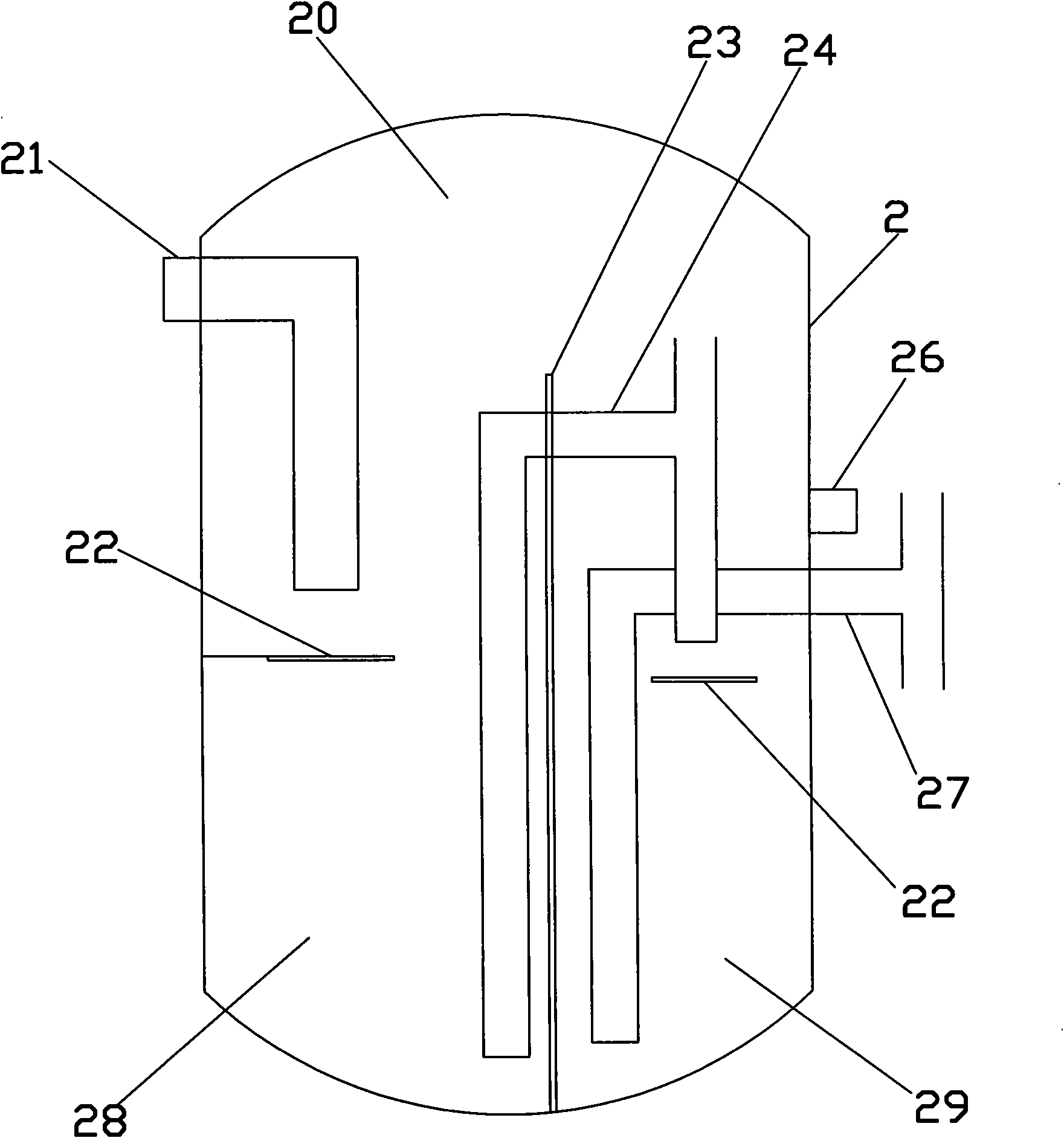

[0032] Such as figure 2The shown double-unit extraction and separation equipment 2 includes a container 20, which is provided with a partition 23 that separates the interior of the container 20 into two spaces, wherein the top of the first space 28 is provided with a feed pipe 21 and a first heavy The phase separation pipe 24 is provided with a material blocking plate 22 below the outlet of the feed pipe 21, the inlet of the first heavy phase separation pipe 24 is located in the lower part of the first space 28, and the outlet of the first heavy phase separation pipe 24 is located in the first space. In the second space 29, the heights of the feed pipe 21, the upper end of the dividing plate 23, and the first heavy phase separation pipe 24 are successively reduced; the second space 29 is provided with a second heavy phase separation pipe 27 and a light phase separation pipe. 26. The inlet of the second heavy phase separation pipe 27 is located in the lower part of the second ...

Embodiment 3

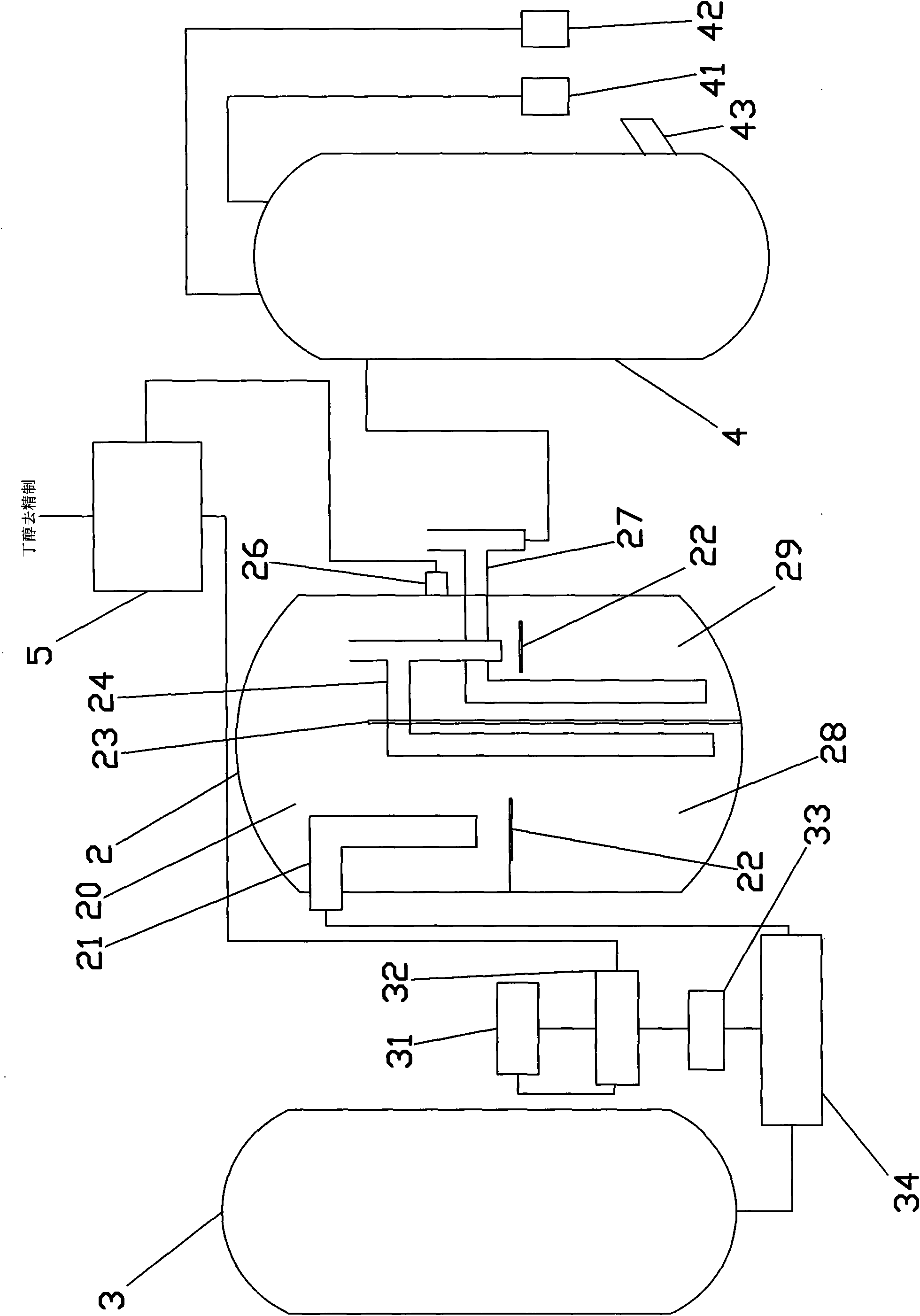

[0036] Such as Figure 4 The device for producing bio-butanol by continuous extraction and fermentation shown includes a previous fermentor 3 and a next fermentor 4, and between the previous fermentor 3 and the next fermentor 4 is a series of double-unit extraction and separation equipment 2 and a single unit. The unit extraction and separation equipment 1 is connected, and the previous fermentation tank 3 and the double-unit extraction and separation equipment 2 are provided with a stirring mixer 34, and the extraction agent inlet pipe of the entrance of the stirring mixer 34 is connected with a cooler 33, a heat exchanger 32, and a heater 31 Connect, the outlet of rectifying device 5 is connected with heat exchanger 32; The light phase separating pipe 26 of double unit extraction separation equipment 2 is connected with the feed pipe 11 of single unit extraction separation equipment 1, the light phase of single unit extraction separation equipment 1 The phase separation pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com