Roller fire grate garbage incinerator and preheating combustion method

A waste incinerator, drum furnace technology, applied in the direction of combustion method, combustion type, combustion equipment, etc., can solve the problems of insufficient drying of garbage, poor turning effect, insufficient drying section, etc., to achieve stable garbage combustion, increase combustion temperature, The effect of reducing pollution emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

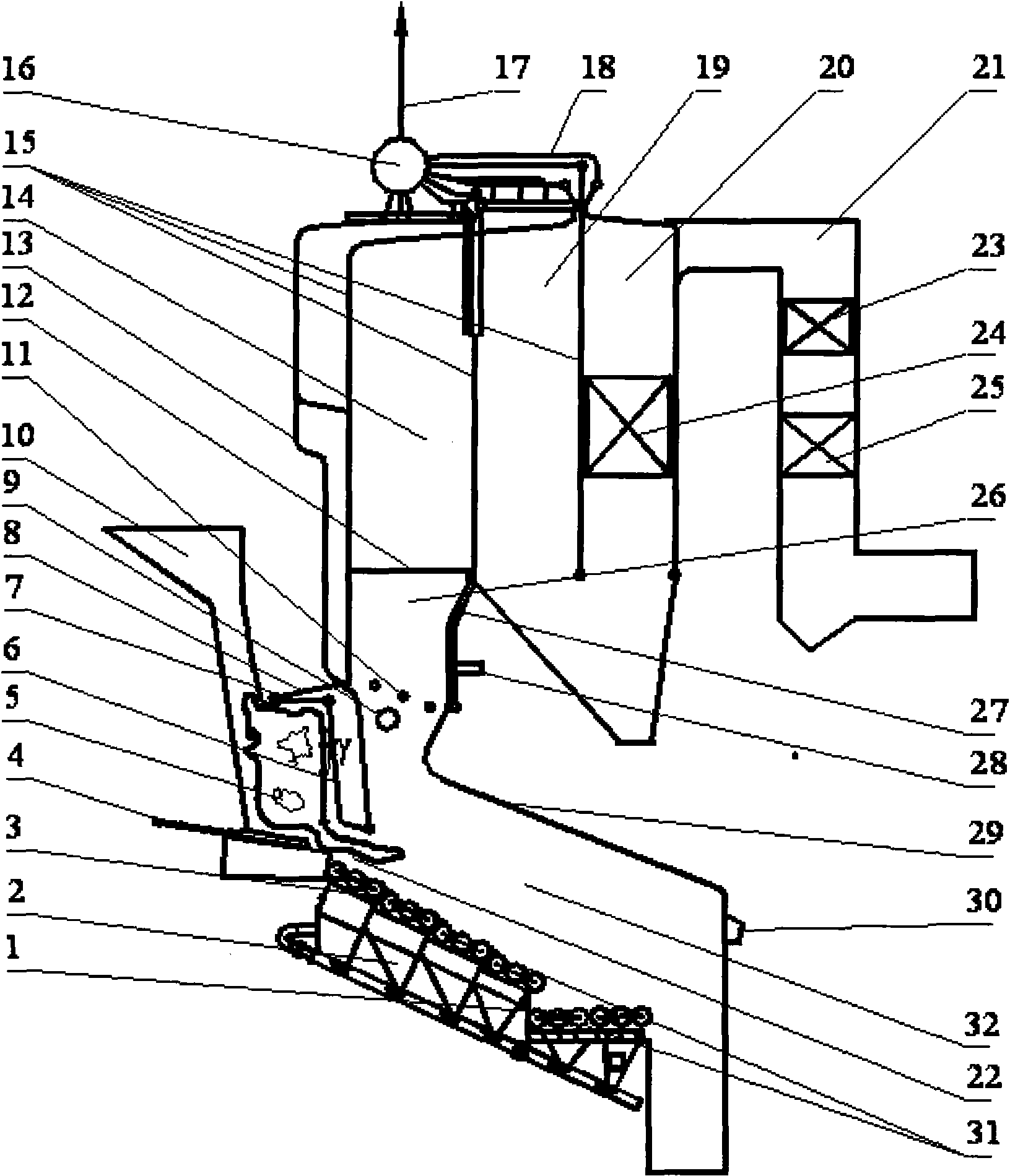

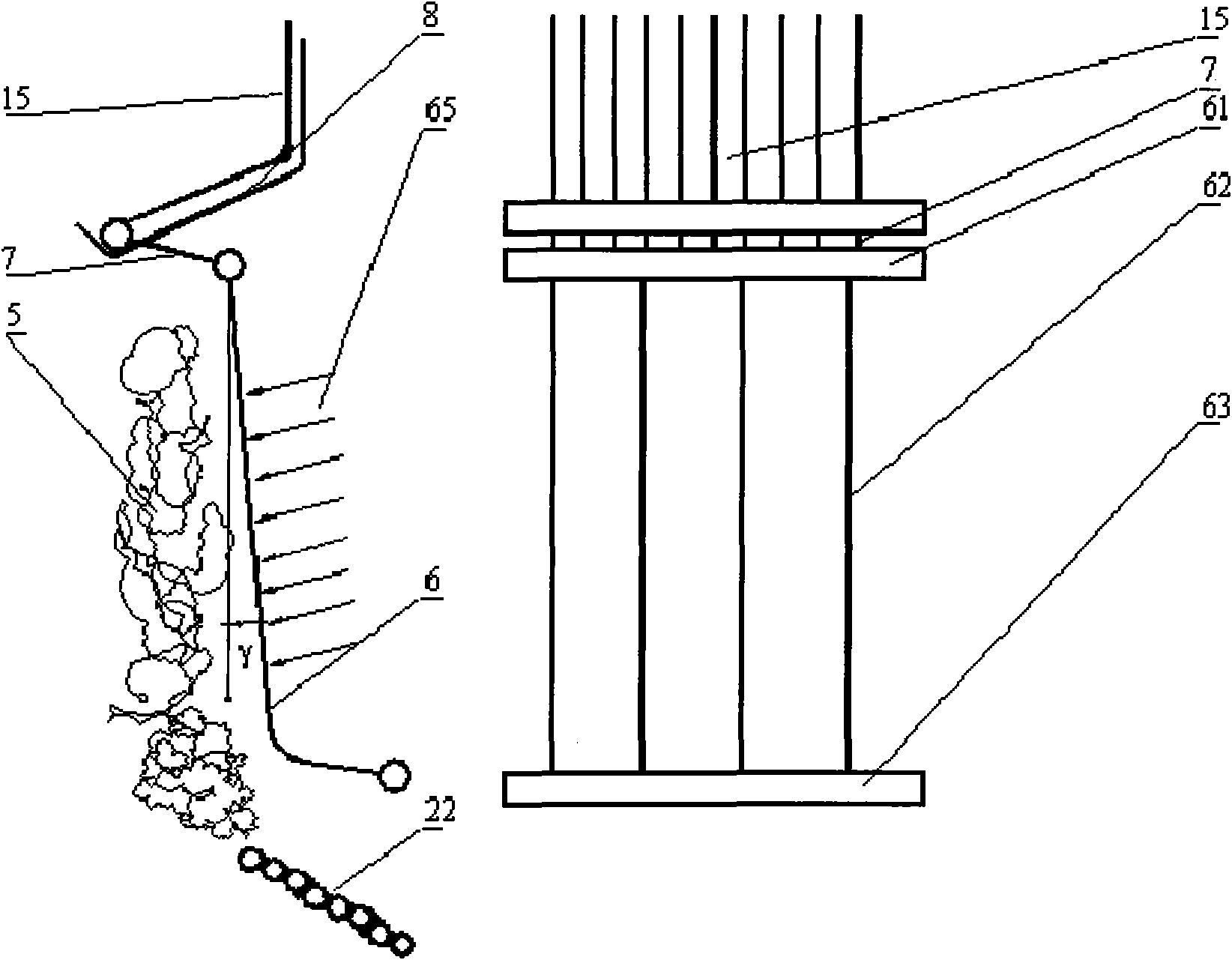

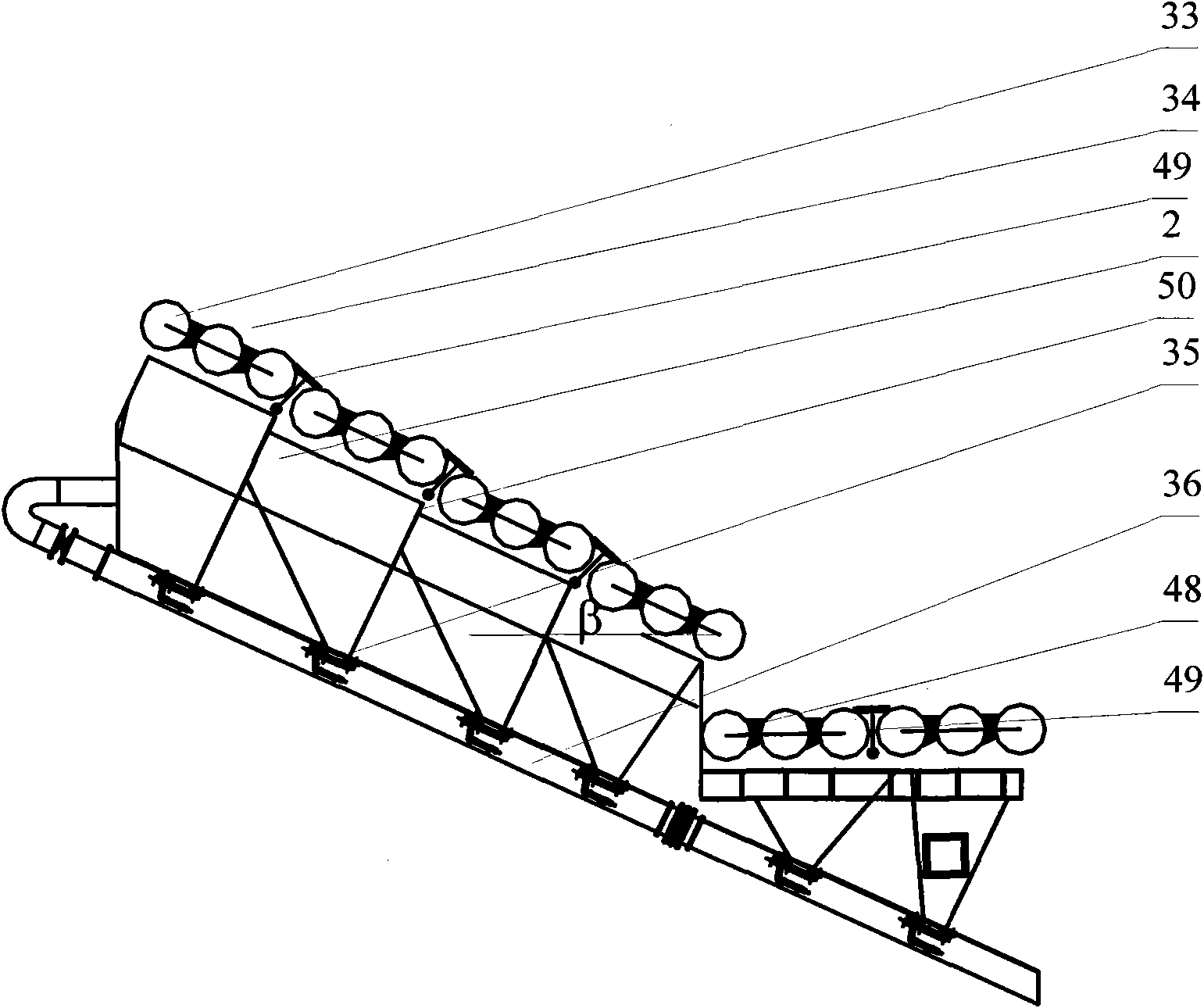

[0025] figure 1 It is a schematic diagram of the overall structure of the drum grate garbage incinerator provided by the present invention. Air nozzle 28, first channel 19, second channel 20, third channel 21, furnace water wall 15. The drum grate 31 comprises some drum groups 34, and each drum group is made up of 3~5 drums 33 (referring to image 3 ). Each roller set 34 is driven separately via a transmission 57 . The drum grate 31 is divided into two parts, the dry combustion section 3 and the burnout section 1, according to its position. The dry combustion section 3 is located at the front of the drum grate 31 and is arranged obliquely, and the burnout section 1 is located at the rear of the drum grate and is arranged horizontally. Each drum group 34 is configured with a primary air distribution bin air chamber 2 , and the drum 33 is composed of a drum mandrel 54 , spokes 52 , and a transmission device 57 . In order to prolong the drying process, a drying grid 6 is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com