Preparation method of antitoxin suitable for high pressure conversion

A high-voltage conversion and anti-toxic agent technology, which is applied in chemical instruments and methods, catalyst protection, physical/chemical process catalysts, etc., can solve the problems of heterogeneous polycrystalline spinel materials, complex processes, and difficulty in homogenization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

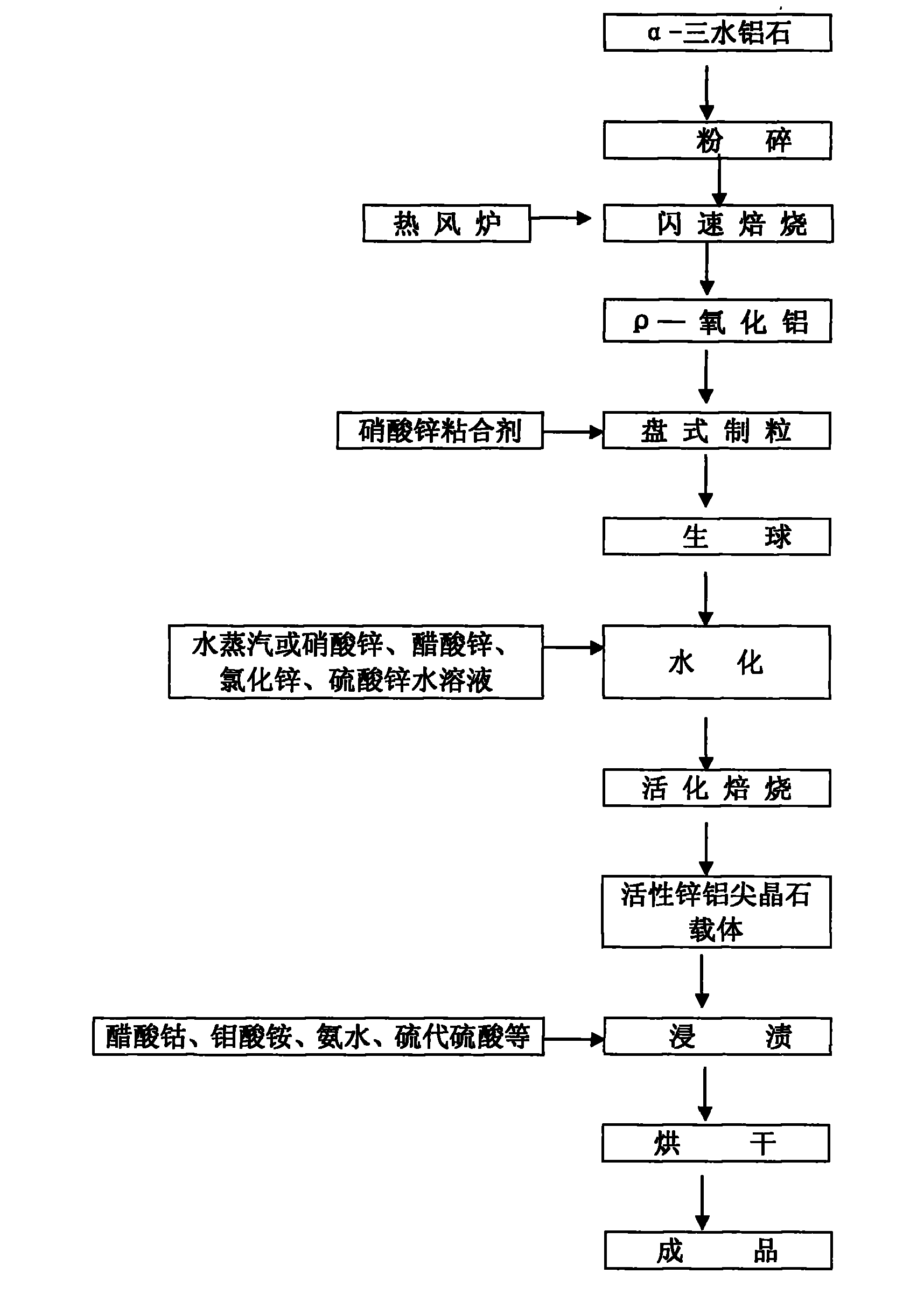

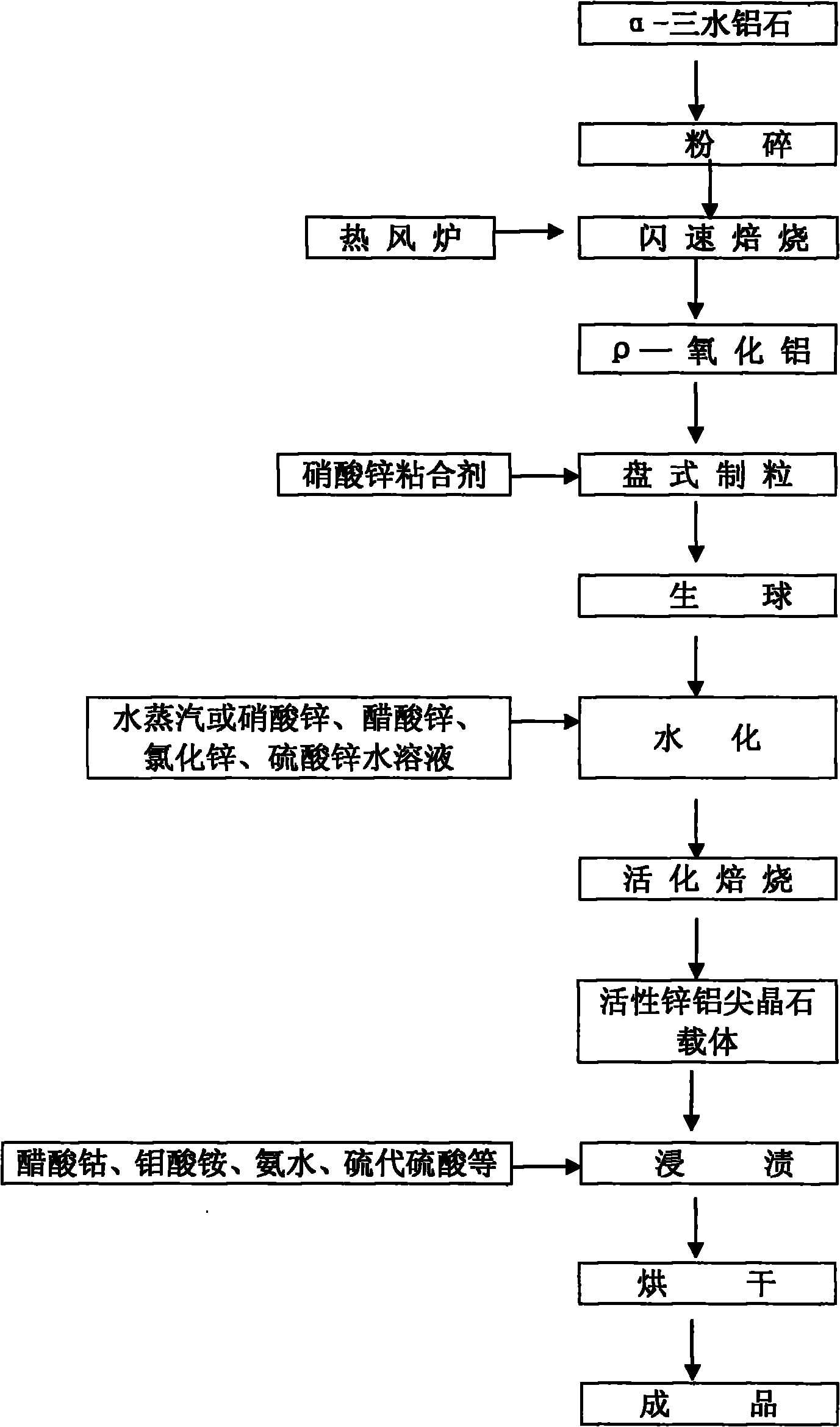

[0027] according to figure 2 After the raw material (α-gibbsite) is dried, it is crushed to 325 mesh in the crushing process, and the fine α-gibbsite is placed in a high-temperature rapid dehydration device, and the hot gas at 600-900°C is in a highly turbulent hot air flow Stay in the middle for 0.1 to 1 second for flash roasting to generate transition state alumina; then through the cyclone separator, after separation, the fine powder is added with a concentration of 40% zinc acetate (in terms of mass percentage) as a binder, and the The raw balls of the required size are made in a type granulator, and then soaked in hot water, and continuously fed with steam to complete the hydration process. In the final activation process, the spherical zinc-aluminum spinel carrier is prepared by roasting at 600-900°C. The carrier is co-impregnated with 3% cobalt acetate (in terms of its mass percentage), 7% of ammonium molybdate (in its mass percentage), etc. in an ammonia solution, an...

Embodiment 2

[0029] according to figure 2 After the raw material (α-gibbsite) is dried, it is crushed to 325 mesh in the crushing process, and the fine α-gibbsite is placed in a high-temperature rapid dehydration device, and the hot gas at 600-900°C is in a highly turbulent hot air flow Stay in the middle for 0.1~1 second to carry out flash roasting, generate transitional state alumina; then through the cyclone separator, after the separation, the fine powder is added with a concentration of 40% zinc chloride (in terms of its mass percentage) as a binder, in The raw balls of the required size are made in the disc granulator, and then soaked in hot water, and continuously fed with steam to complete the hydration process. In the final activation process, the spherical zinc-aluminum spinel carrier is prepared by roasting at 600-900°C. The carrier is co-impregnated with 3% cobalt acetate (in terms of its mass percentage), 7% of ammonium molybdate (in its mass percentage), etc. in an ammonia ...

Embodiment 3

[0031] according to figure 2 After the raw material (α-gibbsite) is dried, it is crushed to 325 mesh in the crushing process, and the fine α-gibbsite is placed in a high-temperature rapid dehydration device, and the hot gas at 600-900°C is in a highly turbulent hot air flow Stay in the middle for 0.1-1 second for flash roasting to generate transition state alumina; then through the cyclone separator, after separation, the fine powder is added with a concentration of 40% zinc sulfate (in terms of its mass percentage) as a binder, and the The raw balls of the required size are made in a type granulator, and then soaked in hot water, and continuously fed with steam to complete the hydration process. In the final activation process, the spherical zinc-aluminum spinel carrier is prepared by roasting at 600-900°C. The carrier is co-impregnated with 3% cobalt acetate (in terms of its mass percentage), 7% of ammonium molybdate (in its mass percentage), etc. in an ammonia solution, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com