Ni-Pt-Ru-Al composite coating and method for preparing same

A ni-pt-ru-al, composite coating technology, applied in coatings, chemical instruments and methods, metal material coating processes, etc., can solve the problem of nickel-based alloys being incompetent, and improve high temperature oxidation resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

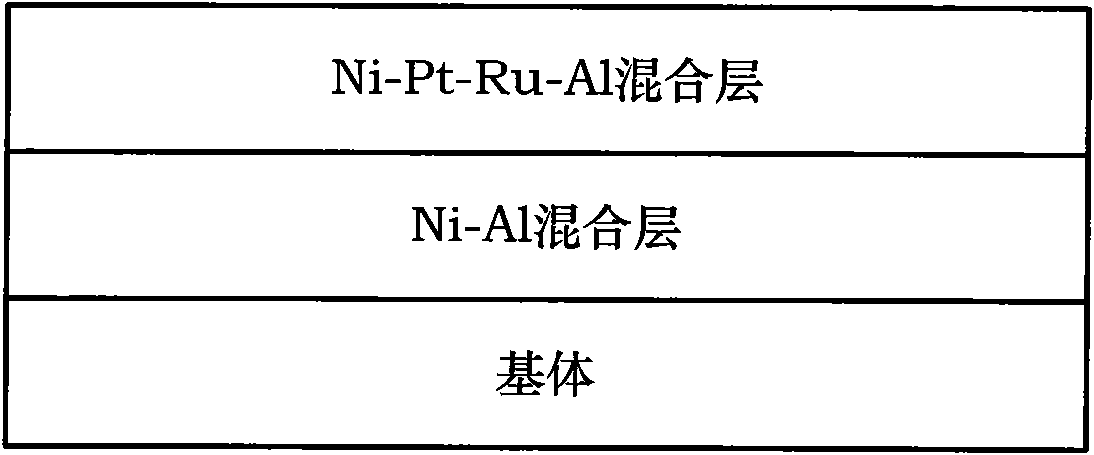

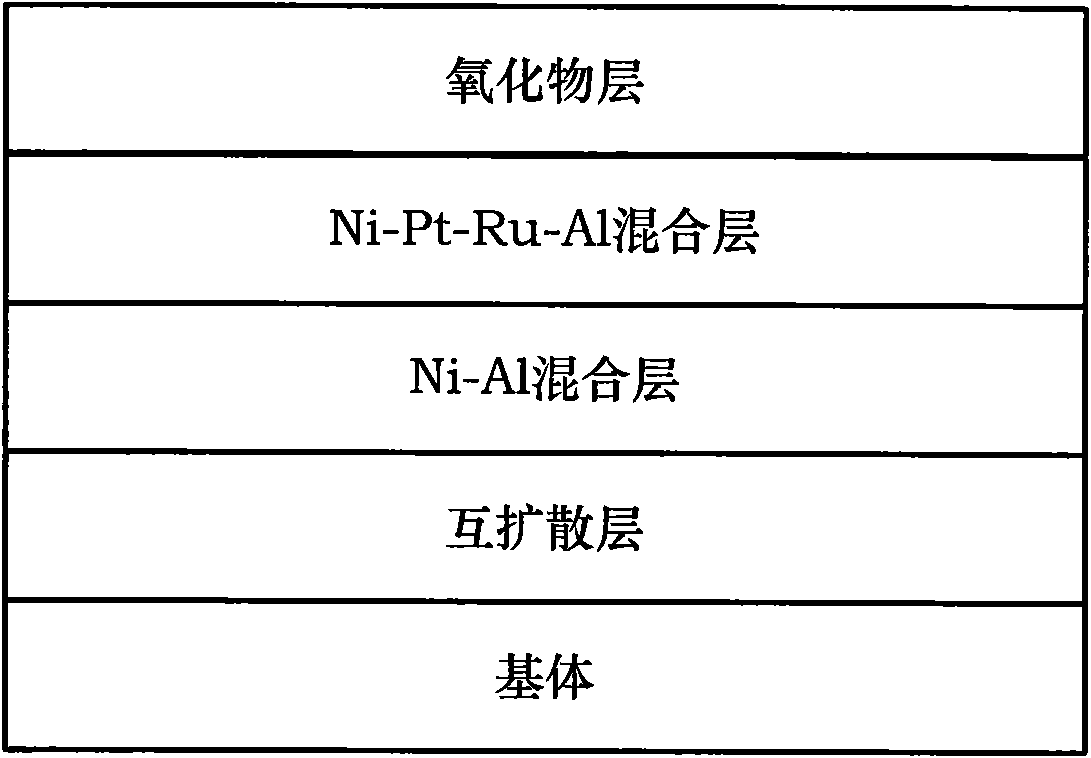

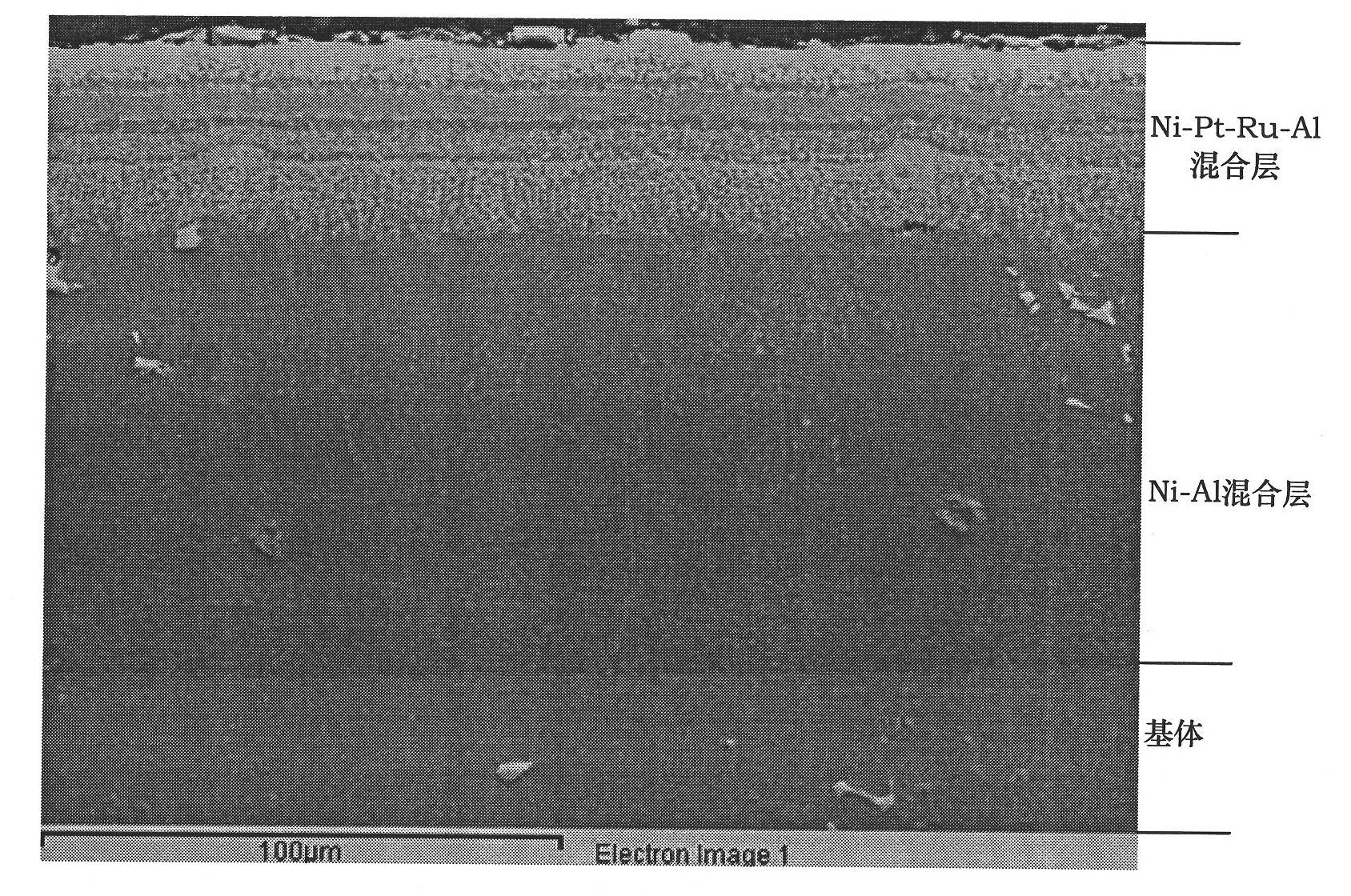

[0019] The present invention is a kind of method for preparing Ni-Pt-Ru-Al composite coating by adopting electroplating and embedding infiltration combined process, and this coating preparation method has the following steps:

[0020] The first step: pretreatment of the substrate

[0021] (A) The surface of the Ni-10Co-9Cr-7.5W-5.4Al-4.1Ta-2.5Mo-1.8Hf-1.2Ti substrate was polished with 120# SiC water abrasive paper to obtain the first sample;

[0022] (B) After the first sample was put into absolute ethanol and ultrasonically cleaned for 5 minutes, the second sample was obtained;

[0023] (C) Putting the second sample into the electrolytic degreasing solution for electrochemical degreasing to obtain the third sample;

[0024] Degreasing process parameters: the second sample is used as the cathode, the anode uses Pt electrode, and the cathode current density is 1.0~1.5A / dm 2 , the degreasing time is 20s~30s;

[0025] (D) Rinse the third sample with deionized water for 1 to 5 ...

Embodiment 1

[0055] The first step: pretreatment of the substrate

[0056] (A) The surface of the Ni-10Co-9Cr-7.5W-5.4Al-4.1Ta-2.5Mo-1.8Hf-1.2Ti substrate was polished with 120# SiC water abrasive paper to obtain the first sample;

[0057] (B) Put the first sample into absolute ethanol and ultrasonically clean it for 5 minutes to obtain the second sample;

[0058] (C) Putting the second sample into the electrolytic degreasing solution for electrochemical degreasing to obtain the third sample;

[0059] Degreasing process parameters: the second sample is used as the cathode, the anode is a Pt electrode, and the cathode current density is 1.0A / dm 2 , the degreasing time is 20s;

[0060] (D) After the third sample was rinsed with deionized water for 3 times, put into the activation solution and activated for 20 seconds, the fourth sample was obtained;

[0061] The composition of the electrolytic degreasing solution is 50ml / L of Na 2 CO 3 and 5ml / L dish soap;

[0062] The activation solut...

Embodiment 2

[0091] The first step: pretreatment of the substrate

[0092] (A) The surface of the Ni-10Co-9Cr-7.5W-5.4Al-4.1Ta-2.5Mo-1.8Hf-1.2Ti substrate was polished with 120# SiC water abrasive paper to obtain the first sample;

[0093] (B) Put the first sample into absolute ethanol and ultrasonically clean it for 5 minutes to obtain the second sample;

[0094] (C) Putting the second sample into the electrolytic degreasing solution for electrochemical degreasing to obtain the third sample;

[0095] Degreasing process parameters: the second sample is used as the cathode, the anode uses Pt electrode, and the cathode current density is 1.5A / dm 2 , the degreasing time is 30s;

[0096] (D) After the third sample was rinsed 5 times with deionized water, put into the activation solution and activated for 30 seconds, the fourth sample was obtained;

[0097] The electrolytic degreasing liquid composition is 30ml / L Na 2 CO 3 and 5ml / L detergent;

[0098] The activation solution consists of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com