Modified epoxy resin composite material of prereacted material of epoxy-terminated silicone oil and preparation method and application thereof

An epoxy-terminated silicone oil, epoxy resin technology, applied in epoxy resin coatings, novolac epoxy resin adhesives, epoxy resin adhesives, etc., can solve the problem of poor mechanical properties and thermal properties, compatibility The problems such as poor performance and incomplete bonding of epoxy-terminated silicone oil to achieve the effect of increasing toughness and thermal stability, good compatibility and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

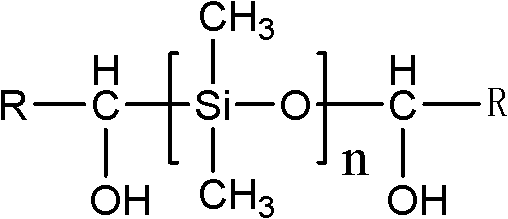

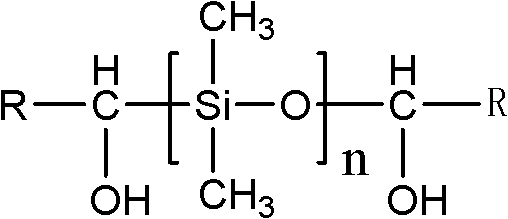

Method used

Image

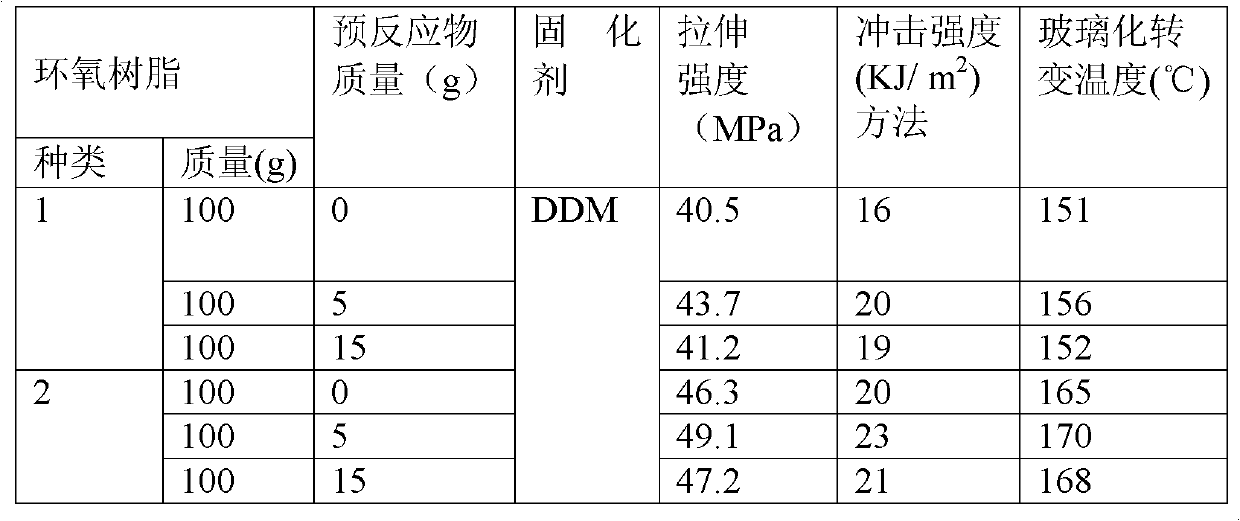

Examples

Embodiment 1

[0040] (1) Get 100g of epoxy-terminated silicone oil with an epoxy value of 0.1mol / 100g (produced from Shanghai Sili Industry and Trade Co., Ltd.) and 6g of ethylenediamine (the molar ratio is 1: 2) and place it in the reactor together, Dissolve with 100g xylene. Heated and stirred in an oil bath, and refluxed at 104°C for 15 hours. After the reaction was completed, the reaction mixture was distilled under reduced pressure to remove xylene to obtain an epoxy-terminated silicone oil pre-reactant.

[0041] (2) 100g terminal epoxy silicone oil pre-reactant, 100g E-44 epoxy resin and 30g SiO 2 Put it in a beaker, add 21.8g p-, p-diaminodiphenylmethane, and stir evenly. According to the curing process of 90°C / 3h+150°C / 2h+180°C / 2h, the epoxy resin composite material modified by epoxy-terminated silicone oil pre-reactant is obtained. The measured tensile strength is 50.32MPa, the elongation at break is 12.31%, and the impact strength is 18.73KJ / m 2 , the glass transition temperatu...

Embodiment 2

[0043] (1) Take 100g of epoxy-terminated silicone oil with an epoxy value of 0.1mol / 100g (produced by Shanghai Sili Industry and Trade Co., Ltd.) and 24.8g of diaminodiphenyl sulfone (molar ratio is 1:2) In the reactor, dissolve with 150g of dimethylformamide. Heated and stirred in an oil bath, and refluxed at 105°C for 16 hours. After the reaction, the reaction mixture was distilled under reduced pressure to remove dimethylformamide to obtain a pre-reaction product of epoxy-terminated silicone oil.

[0044] (2) 0.1g terminal epoxy silicone oil pre-reactant, 100g E-32 epoxy resin and 30g SiO 2Place in a beaker, add 19.8g of diaminodiphenyl sulfone, and stir evenly. According to the curing process of 80°C / 1h+160°C / 2h+180°C / 2h, the epoxy resin composite material modified by epoxy-terminated silicone oil pre-reactant is obtained. The measured tensile strength is 43.18MPa, the elongation at break is 10.27%, and the impact strength is 16.35KJ / m 2 , the glass transition temperatu...

Embodiment 3

[0046] (1) Get 100g of epoxy-terminated silicone oil (produced from Shanghai Sili Industry and Trade Co., Ltd.) and 1.98g of epoxy value 0.01mol / 100g to, p-diaminodiphenylmethane (molar ratio is 1: 2) Put them together in a reactor and dissolve them with 100g of toluene. Heated and stirred in an oil bath, and refluxed at 106°C for 16 hours. After the reaction, the reaction mixture was distilled under reduced pressure to remove toluene to obtain a pre-reactant of epoxy-terminated silicone oil.

[0047] (2) 10g terminal epoxy silicone oil pre-reactant, 100g BPF-45 epoxy resin and 50g SiO 2 Put it in a beaker, add 22.3g p-, p-diaminodiphenylmethane, and stir evenly. According to the curing process of 90°C / 3h+150°C / 2h+180°C / 2h, the epoxy resin composite material modified by the epoxy-terminated silicone oil pre-reactant is obtained. The measured tensile strength is 52.79MPa, the elongation at break is 14.28%, and the impact strength is 20.15KJ / m 2 , The glass transition tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com