Method for leaching metal from metallic ores and special strain in same

A metal and ore technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, bacteria, etc., can solve the problems of bacterial inactivation, loss of vitality, pH value reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

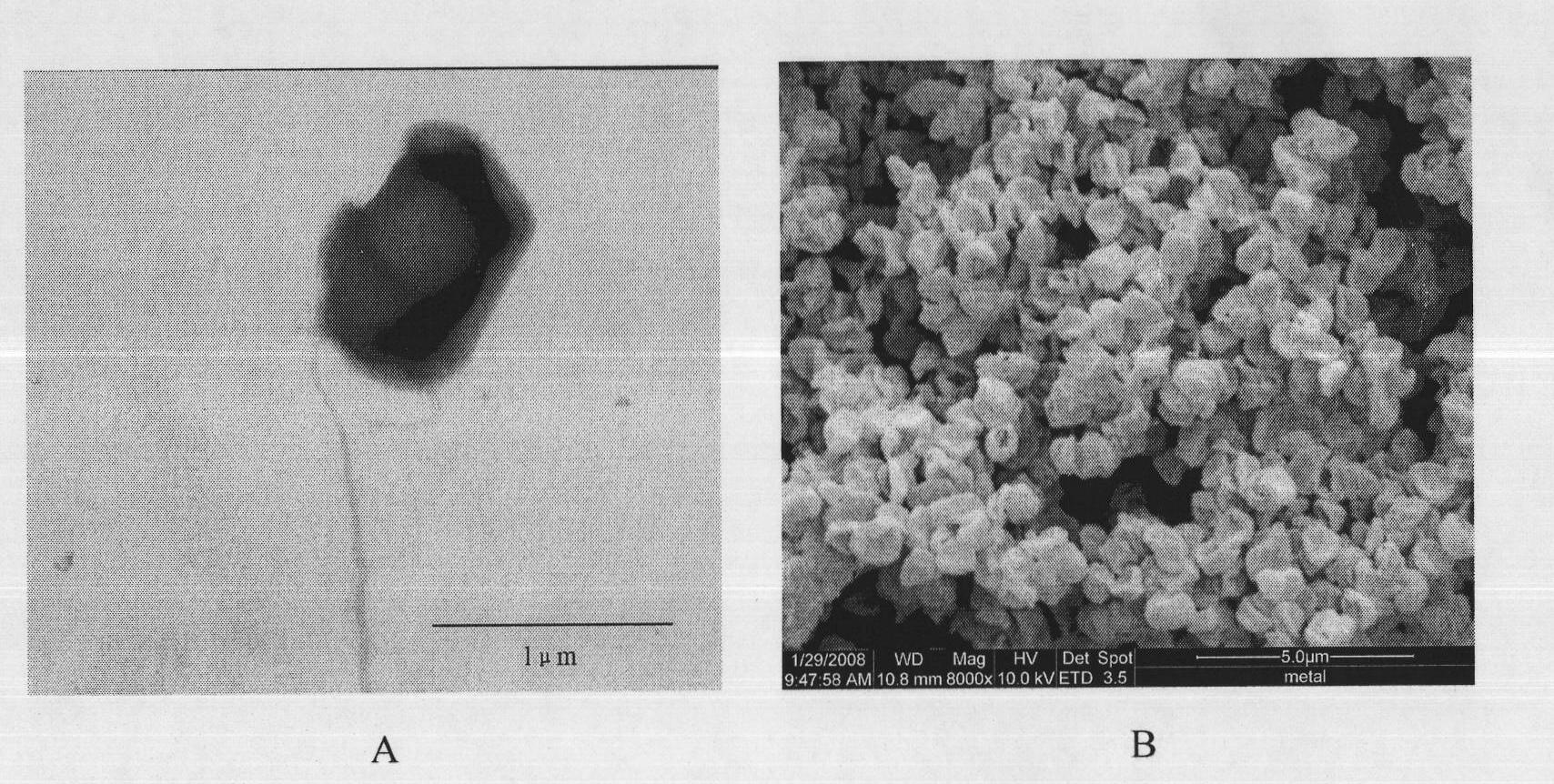

[0044] Example 1. Isolation and identification of bacteria

[0045] 1. Separation

[0046] The strain of the present invention is obtained by separation and purification from the sulfur-rich hot spring mud sample in Tengchong County, Yunnan Province, China, and the separation and purification time is June 6, 2008.

[0047] The enrichment of microorganisms is carried out by adding 100 mL of basal medium to a 250 mL shake flask, weighing 5 grams of hot spring mud sample into the sterile basal medium, adding 5-10 g of sulfur, and enriching culture at 65°C. After one week of cultivation, check the growth of bacteria under a microscope. After enrichment for three times, dilute the enrichment medium 10 times, take 0.2mL of the diluted medium and spread it on a plate to separate the single clones, and add 7g / L Gelrite gum to the solid medium on the basis of the liquid medium to use tetrathionic acid Potassium replaces elemental sulfur as energy. Through multiple streaking cultures, a mon...

Embodiment 2

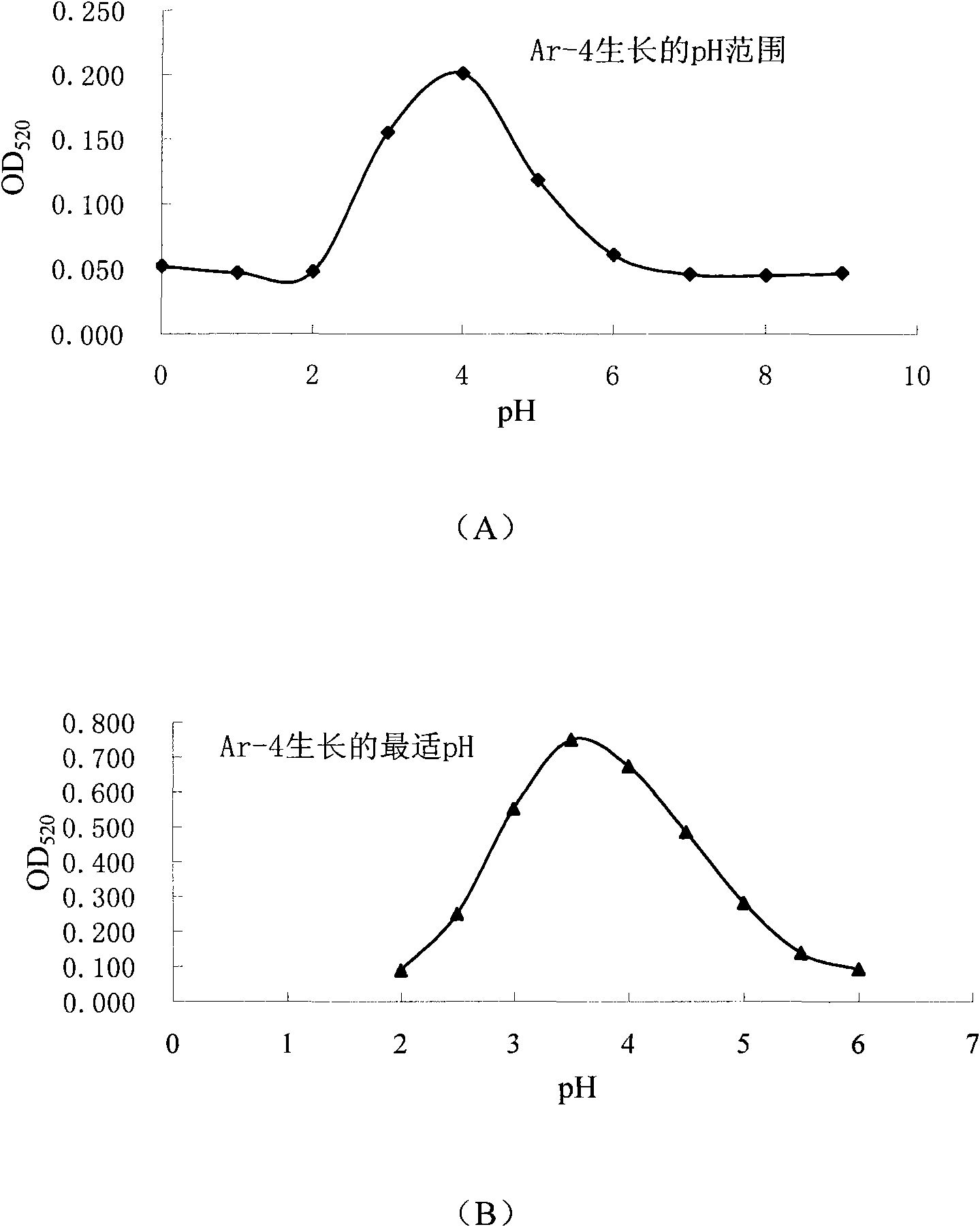

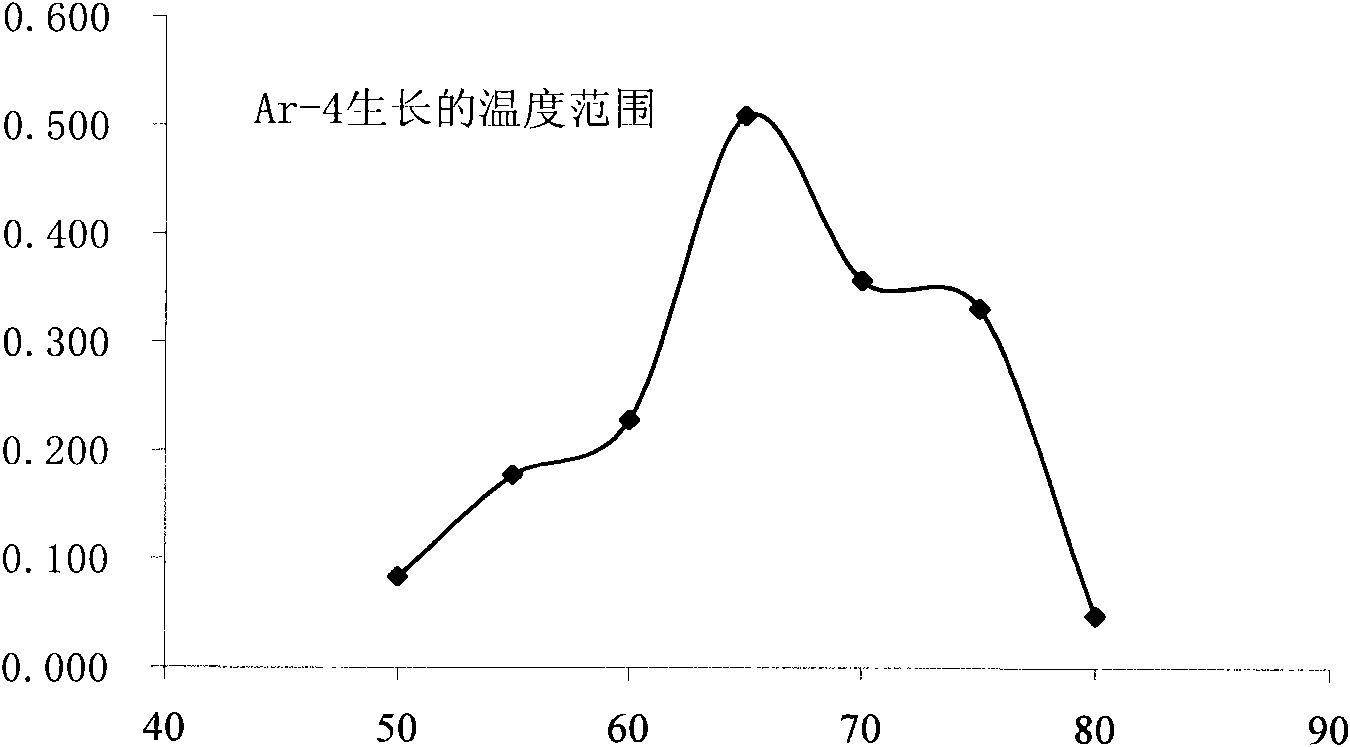

[0067] Example 2: Cultivation of bacteria

[0068] 1. Training method

[0069] (1) Autotrophic cultivation

[0070] Composition of autotrophic medium: FeSO was added to the basic medium separately 4 ·7H 2 O or elemental sulfur or reduced sulfide K 2 S 4 O 6 , Get autotrophic medium; FeSO 4 ·7H 2 The concentration of O in the autotrophic medium is 13.9g / L, the concentration of elemental sulfur in the autotrophic medium is 5g / L, and the reduced sulfide K 2 S 4 O 6 The concentration in the autotrophic medium is 10g / L; the pH is adjusted to 2.0-3.5.

[0071] Cultivation method: inoculate the acidophilus thermophilus (Metallosphaera sp.) Ar-4CGMCC No.3402 in an autotrophic medium and cultivate it at 65°C.

[0072] (2) Heterotrophic culture

[0073] Heterotrophic medium composition: adding yeast extract to the basic medium, the ratio of the yeast extract to the basic medium is 1g:1L; adjusting the pH value to 2.5-3.5, and autoclaving. Among them, yeast extract is an energy substance.

[0074] ...

Embodiment 3

[0082] Example 3. Application of bacteria

[0083] Yeast extract was purchased from Oxoid Ltd, the product catalog number is 1039501;

[0084] 1. Study on the ability to dissolve pyrite of Metallosphaera sp. (Metallosphaera sp.) Ar-4CGMCC No.3402

[0085] Metallosphaera sp. (Metallosphaera sp.)Ar-4CGMCC No.3402 extracts total iron (Fe) from pyrite 2+ And Fe 3+ ).

[0086] The ore composition of pyrite: S 45.57%, Fe 42.63%, Cu 0.063%, Zn 0.0076%, As 0.02%:% represents the mass percentage; the source of pyrite: Inner Mongolia Huogeqi Copper Mine.

[0087] Before the experiment, pass the pyrite through a 300-mesh sieve (the average particle size is 48μm), and then use 1:1H 2 SO 4 The aqueous solution (the concentration of sulfuric acid in the sulfuric acid aqueous solution is 50%, v / v) is soaked for 3-5 days, until the pH value of the acidified solution remains unchanged for 24 hours between 1.5-1.6.

[0088] Cultivate the acidophilus thermophilus (Metallosphaera sp.) Ar-4CGMCC No.3402 with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com