Method and device for multi-point on-line detection of digital hydraulic machine column stress

A hydraulic press, digital technology, applied in the field of machinery and electronics, can solve the problems of poor anti-interference ability, inconvenient installation, low detection accuracy, etc., and achieve the effect of avoiding potential safety hazards, prolonging service life, and strong anti-interference ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

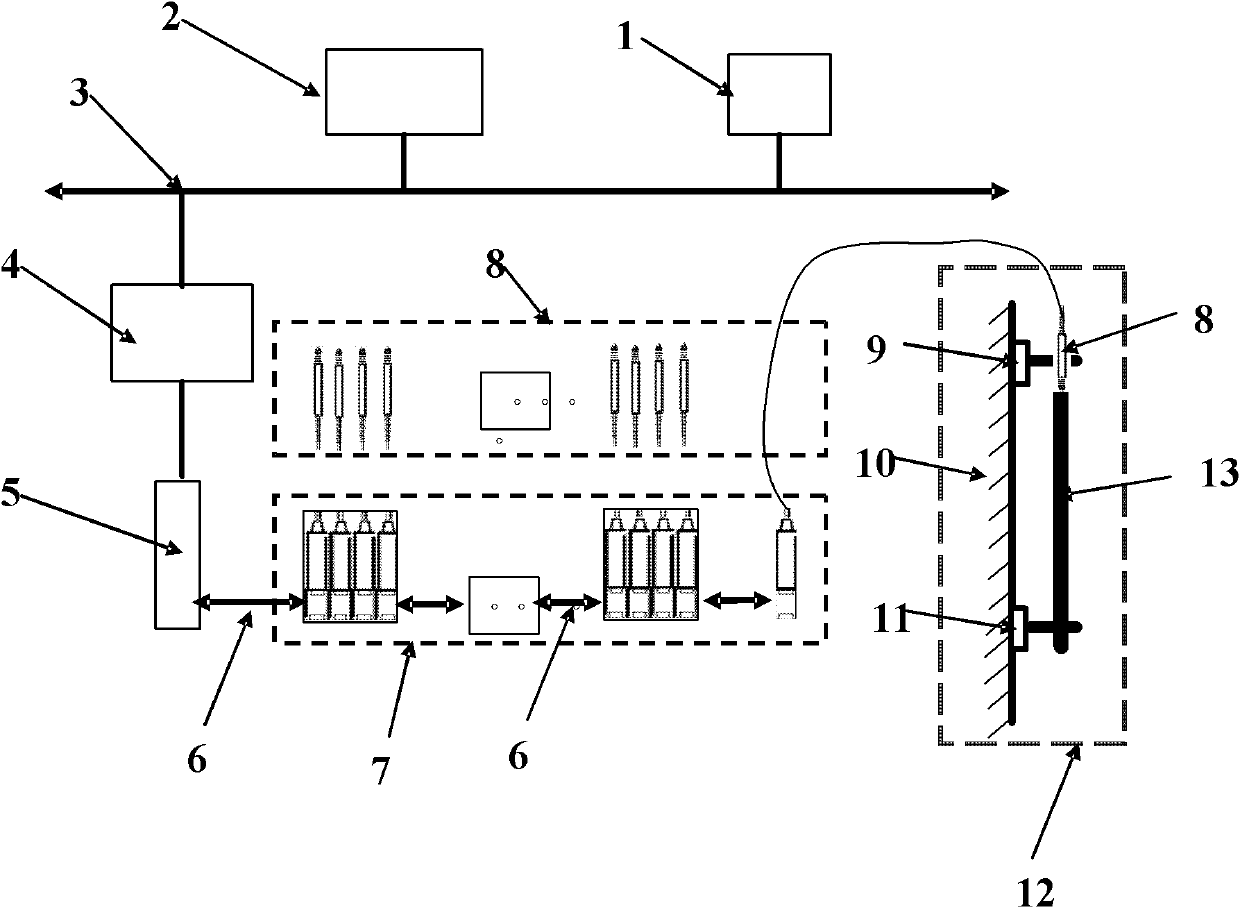

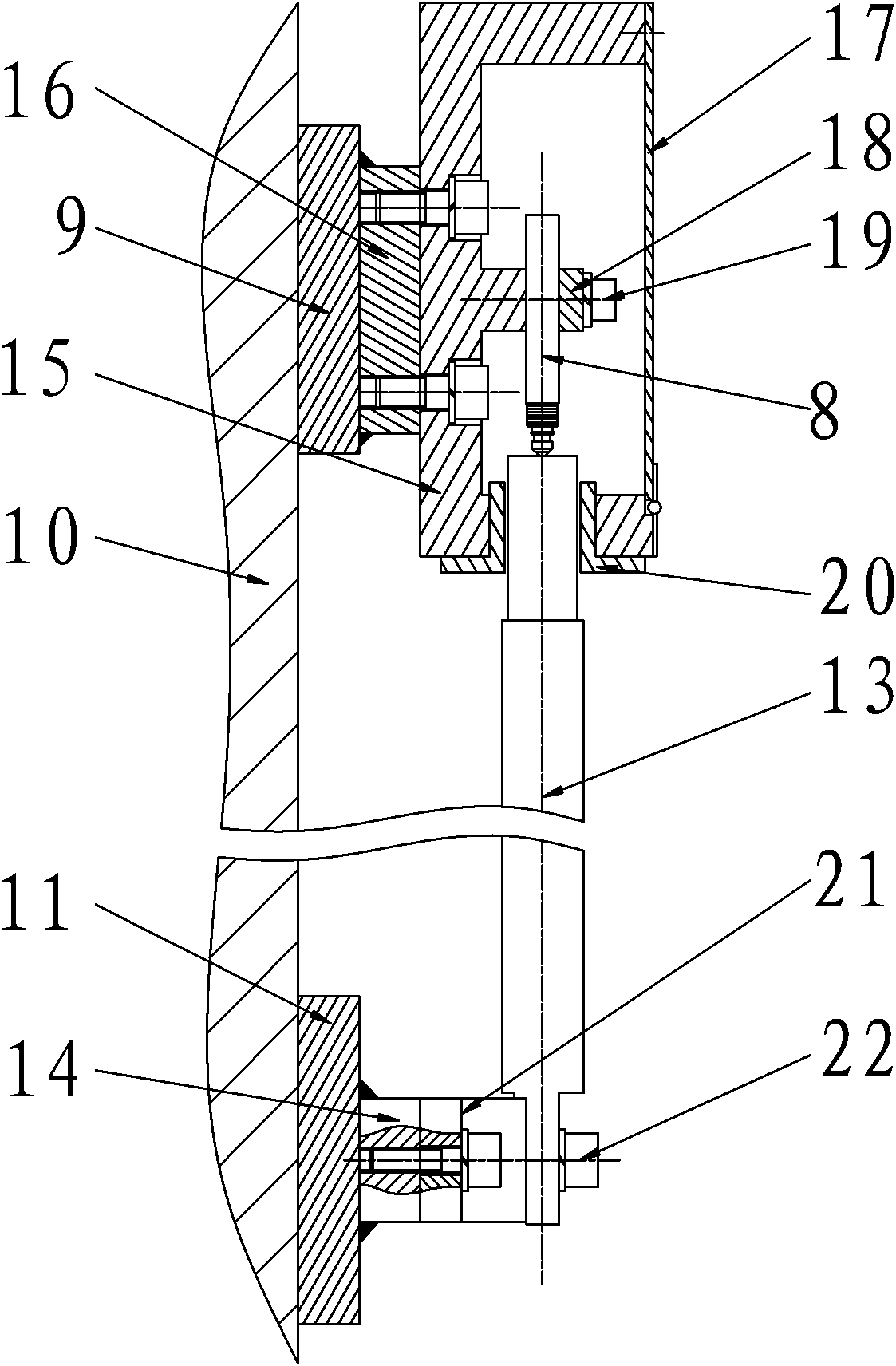

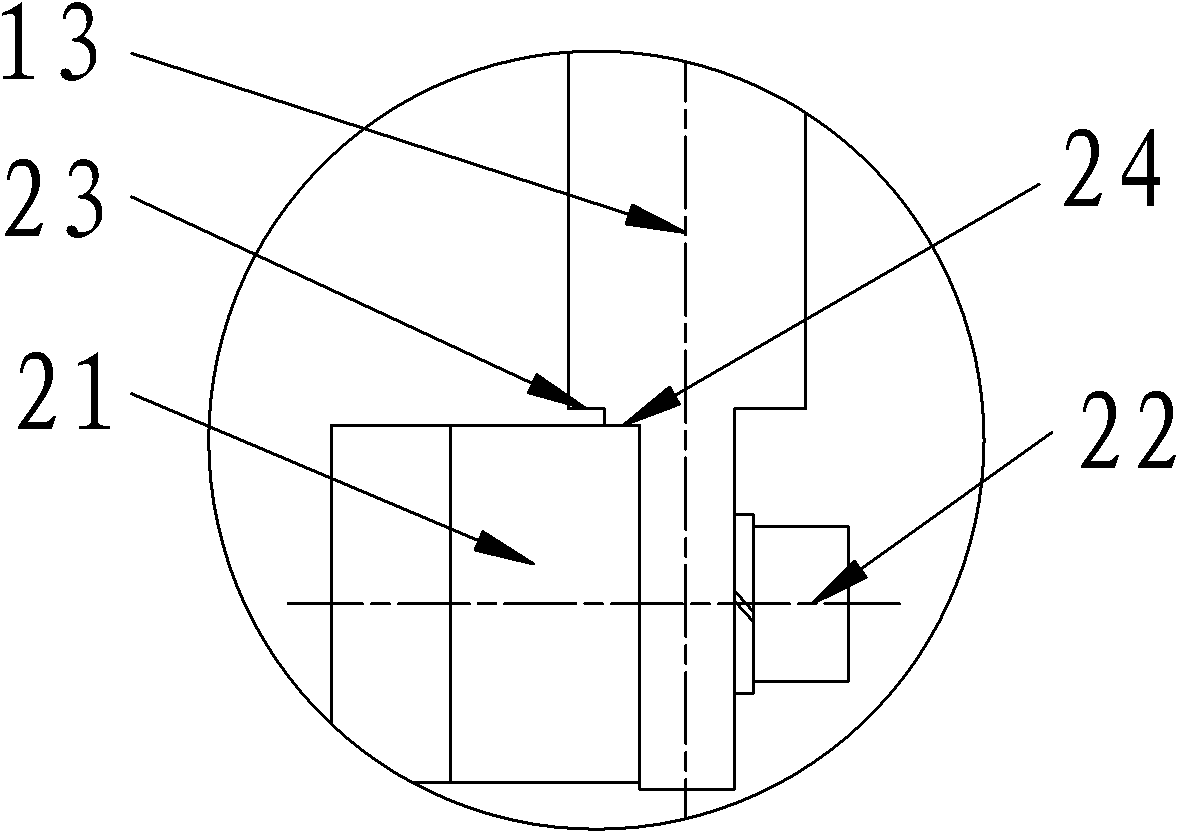

[0033] A digital hydraulic machine column stress multi-point online detection device, including digital sensors, sensor mounting brackets, communication modules, programmable logic controllers (PLC), upper computer monitoring systems and the like. It is characterized in that the two hoops are fixed at the position to be detected on the surface of the column, and the displacement transmission rod is used to transmit the micro deformation of the column between the two hoops when the column is stressed. The micro deformation is detected by a digital sensor, and the digital sensor and the displacement The transmission rod is in contact; the communication between the PLC and the sensor is realized through the communication module, and all the sensors are connected to an RS485 bus; the upper computer monitoring system has column stress display and alarm, sensor status monitoring, zero position and alarm value setting. Fixed and other functions.

[0034] figure 1 Describes the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com