Reactive side chain type liquid crystal copolymer

A technology of side-chain liquid crystals and copolymers, applied in the field of liquid crystal epoxy polymers, can solve the problems of restricted crystal units at both ends, unfavorable liquid crystal unit reorientation and rearrangement, and liquid crystal unit dispersion, etc. Controllable oxygen functionality, improved interfacial compatibility, and high mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Monomer MBPHMA (7.3694 g, 2 × 10 -2 mole), monomer GMA (0.7108 g, 5×10 -3 mole) and initiator AIBN (0.0082 g, 2.5×10 -5 ) was added to the three-necked flask in turn, and the nitrogen was repeatedly pumped three times. Under the protection of nitrogen, 50 ml of solvent THF was added, and the mixed system was rapidly magnetically stirred until the mixed system was clear and colorless. The diluted solution was dropped into methanol with slow magnetic stirring, a white precipitate was precipitated, filtered, and vacuum-dried at 60°C for 6 hours to obtain 7.12 g of a white solid, a reactive side-chain liquid crystal copolymer. Its structural formula is:

[0032]

[0033] Through detection and analysis:

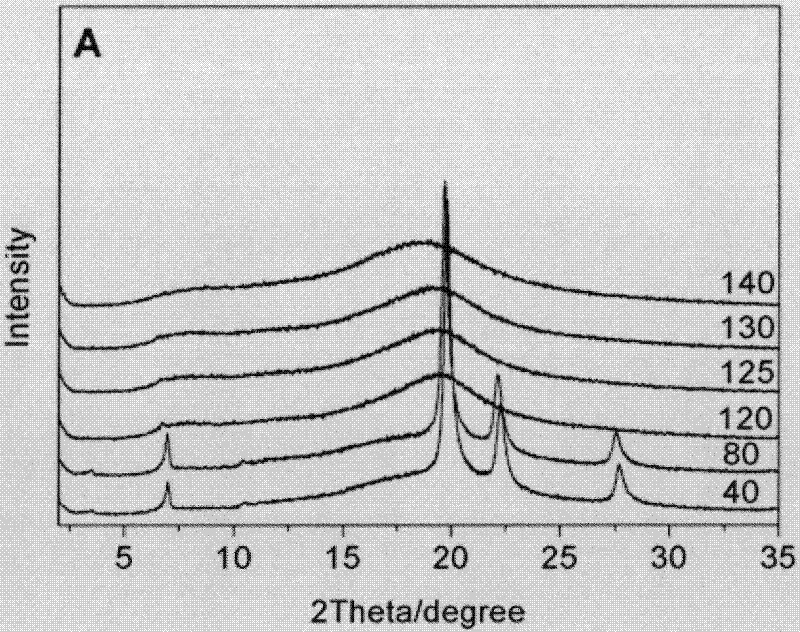

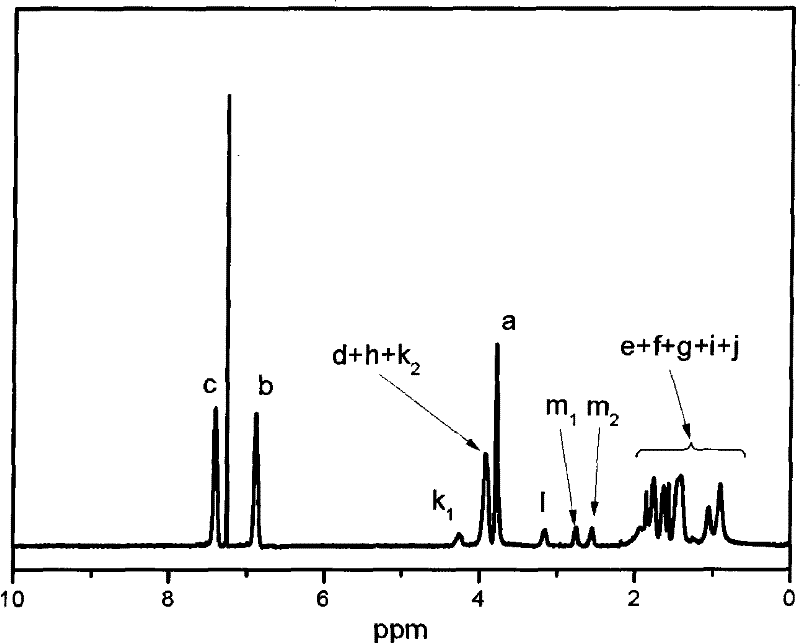

[0034] figure 1 is the NMR spectrum of PMBPHMA-co-PGMA, combined with the general molecular formula of the polymer (the hydrogen atom indicated by the lowercase symbol on it, and figure 1 The peaks indicated by the lowercase letter symbols in the one-to-one corres...

Embodiment 2

[0039] The reaction solvent and diluent were chloroform, and the rest were the same as in Example 1.

Embodiment 3

[0041] The initiator adopts BPO (dibenzoyl peroxide), and the reaction temperature is 80° C., and the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com