Process for production of polyimide film, and polyamic acid solution composition

A technology of polyimide film and manufacturing method, which is applied in the direction of coating, etc., and can solve the problems of foaming, poor formability, difficulty in making polyimide film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

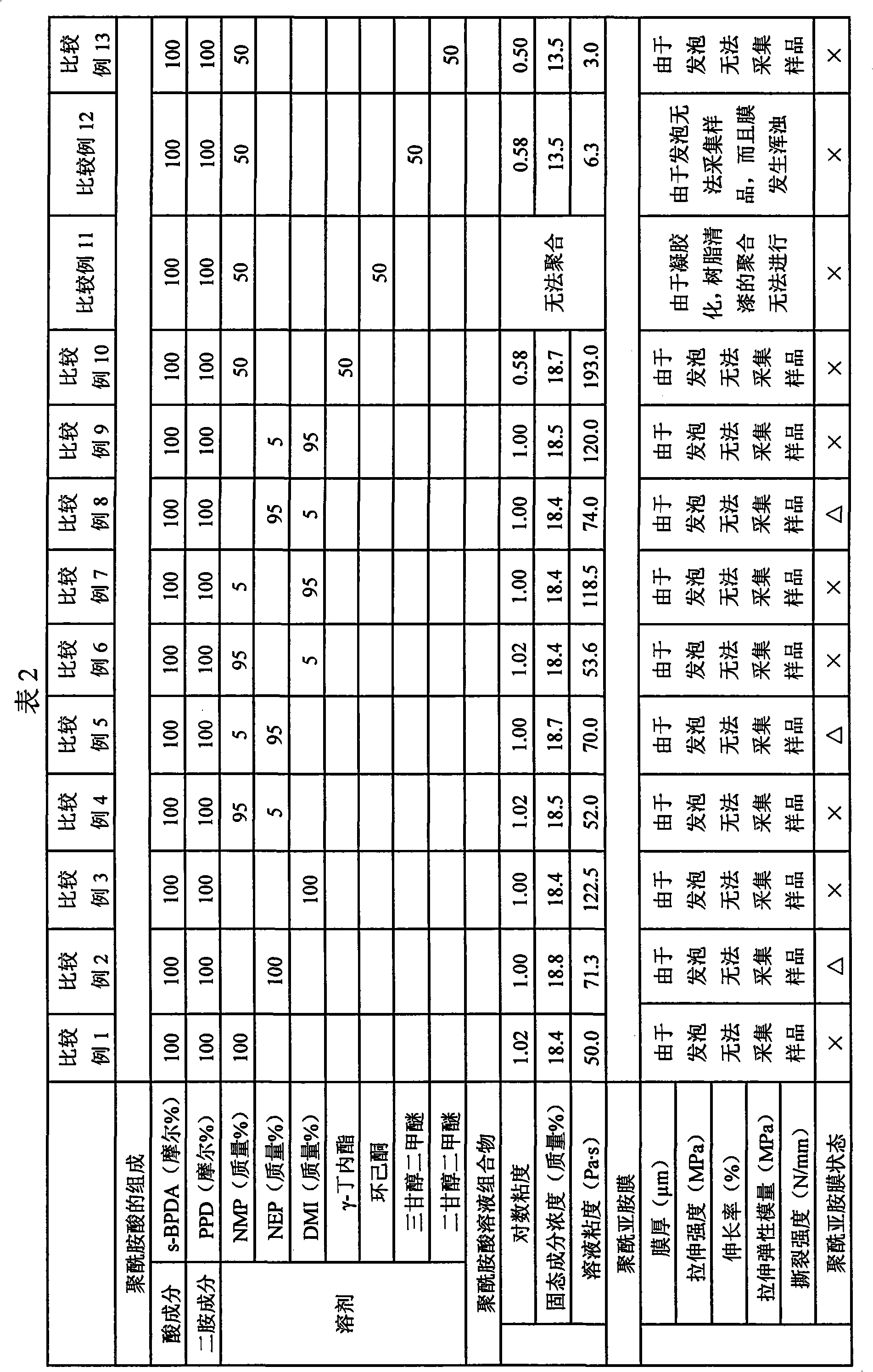

Problems solved by technology

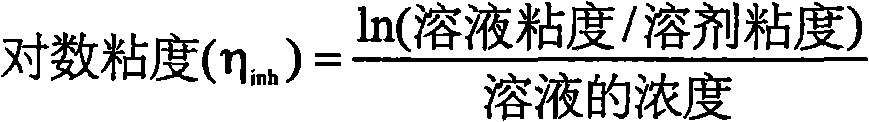

Method used

Image

Examples

preparation example Construction

[0023] The preparation of polyamic acid can preferably adopt the known method or condition for preparing polyamic acid. Therefore, it is not particularly limited, but it is preferable to stir for 0.1 hour to several tens of hours under the temperature conditions for suppressing the imidization of the amide bond and the carboxyl group of the polyamic acid, preferably below 100°C, more preferably below 80°C. For example, tetracarboxylic dianhydride and diamine are reacted in an organic solvent at a concentration of about 5 to 50% by mass in terms of polyimide solid content, thereby obtaining a uniform polyamic acid solution. When the solid content concentration in terms of polyimide is less than 5% by mass, it is uneconomical because a large amount of solvent is used, and when the solid content concentration exceeds 50% by mass, the viscosity tends to become high, making handling difficult.

[0024] As the organic solvent used for the preparation of the polyamic acid, convention...

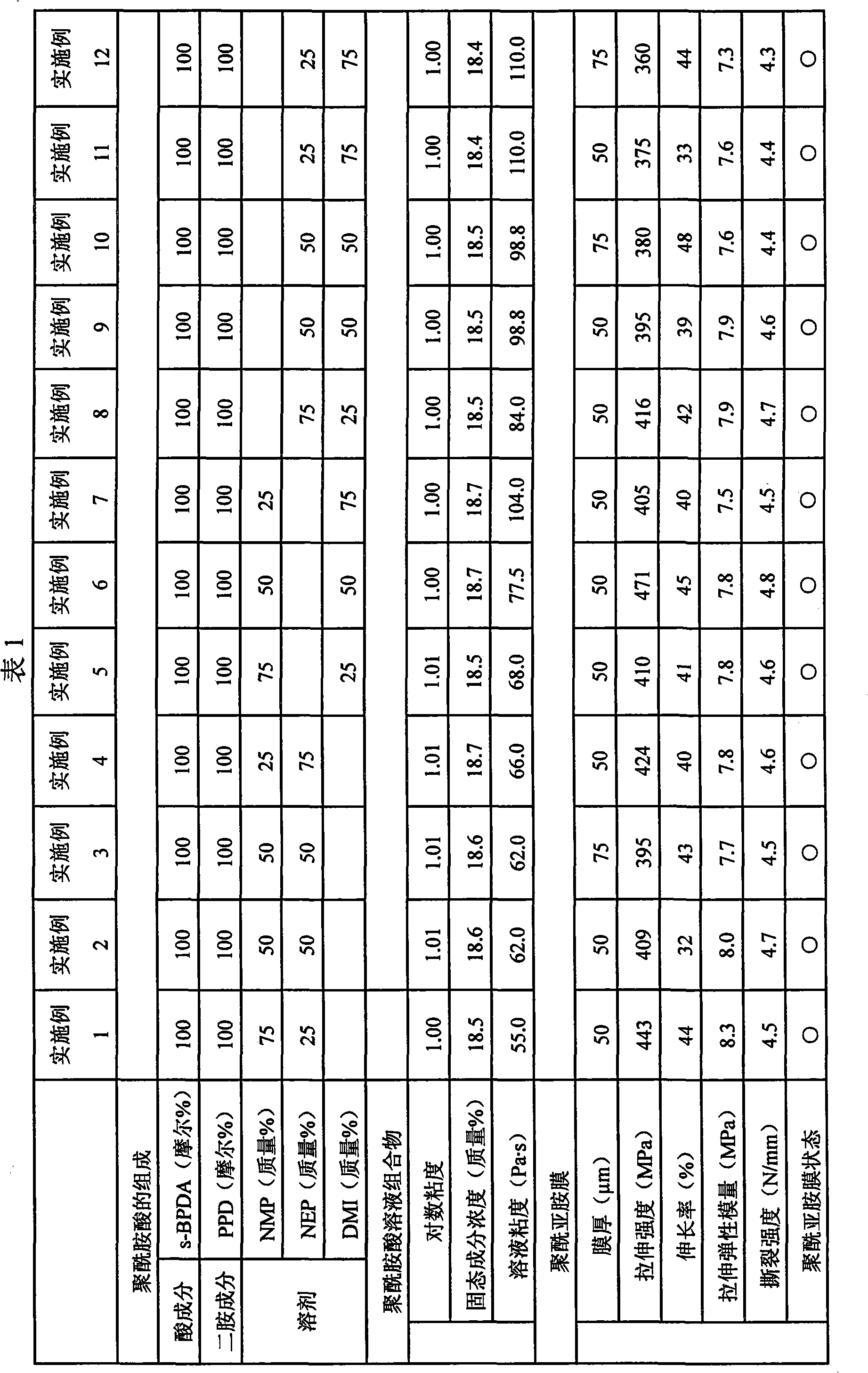

Embodiment 1

[0073] Add NMP 300g (accounting for 75% by mass in the total amount of solvent), NEP 100g (accounting for 25% by mass in the total amount of solvent) as a solvent in a glass reaction vessel with an inner volume of 500ml with a stirrer and a nitrogen gas introduction and discharge pipe. %), PPD 26.88g (0.249 mol) and s-BPDA73.12g (0.249 mol) were added thereto, and stirred at 50°C for 10 hours to obtain a solid content concentration of 18.5% by weight and a solution viscosity of 55.0 Pa·s. A polyamic acid solution composition with a numerical viscosity of 1.00.

[0074] The polyamic acid solution composition is coated on the glass plate of the base material by using a bar coater, and the coating film is degassed and pre-dried for 30 minutes at 25° C. under reduced pressure, and then under normal pressure and nitrogen environment Put it in a hot air dryer, heat treatment at 120°C for 60 minutes, 150°C for 30 minutes, 200°C for 10 minutes, 250°C for 10 minutes, and 400°C for 10 m...

Embodiment 2

[0077] A polyimide film having a film thickness of 50 μm was formed in the same manner as in Example 1 except for using 200 g of NMP (50 mass % in the total solvent) and 200 g of NEP (50 mass % in the total solvent).

[0078] Table 1 shows the results of properties and the like of the polyimide film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com