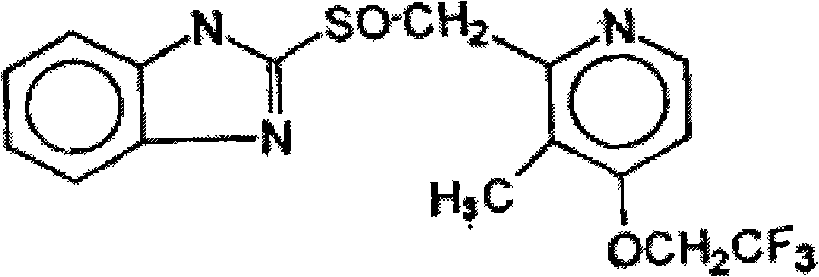

Lansoprazole preparation for injection and preparation method thereof

A technology of lansoprazole and freeze-dried powder for injection is applied in the field of lansoprazole freeze-dried powder for injection and its preparation, and achieves the effect of good clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The prescription of lansoprazole freeze-dried powder preparation:

[0039] Lansoprazole 30g

[0041] Meglumine 10g

[0042] Mannitol 60g

[0043] Preparation Process:

[0044] 1. Wash the vials and stoppers, sterilize, dry and sterilize for later use.

[0045] 2. Dosing: Weigh 10g of meglumine and 4g of sodium hydroxide according to the prescription, dissolve in 80% freshly distilled water for injection, and stir to dissolve. Take by weighing lansoprazole crude drug 30g, stir and dissolve. Weigh 60g of mannitol and add and stir to dissolve. 2 g of activated carbon was stirred at room temperature for 20 minutes, and filtered. Add water for injection to a full volume of 2000ml. First filter with a 0.45μm mixed cellulose ester filter, and then use a double-layer 0.22μm mixed cellulose ester filter to sterilize and filter, and fill in 2ml / bottle.

[0046] 3. Freeze-drying: put the sample into a freeze dryer, place it at -45°C, pre-free...

Embodiment 2

[0048] The prescription of lansoprazole freeze-dried powder preparation:

[0049] Lansoprazole 30g

[0050] Sodium hydroxide 4.1 g

[0051] Meglumine 10g

[0052] Mannitol 60g

[0053] Preparation Process:

[0054] 1. Wash the vials and stoppers, sterilize, dry and sterilize for later use.

[0055] 2. Dosing: Weigh 10 g of meglumine and 4.1 g of sodium hydroxide according to the prescription, dissolve in 80% freshly distilled water for injection, and stir to dissolve. Take by weighing lansoprazole crude drug 30g, stir and dissolve. Weigh 60g of mannitol and add and stir to dissolve. 2 g of activated carbon was stirred at room temperature for 20 minutes, and filtered. Add water for injection to a full volume of 2000ml. First filter with a 0.45μm mixed cellulose ester filter, and then use a double-layer 0.22μm mixed cellulose ester filter to sterilize and filter, and fill in 2ml / bottle.

[0056] 3. Freeze-drying: place the sample in a freeze-drying machine, place it at -4...

Embodiment 3

[0058] Example 3 Freeze-Drying Condition Experiment

[0059] Carry out operation by embodiment 1, except that the freeze-drying process is different, other is the same, take the moisture of freeze-dried product, related substances and resolubility as investigation index, determine the best freeze-drying process, the results are shown in Table 1

[0060] Table 1 Investigation of freeze-drying process conditions

[0061]

[0062] From the above experimental results, from the production cost control and the actual situation, it is determined that the second batch is the best freeze-drying process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com