Preparation method of SiBOC precursor

A technology of precursor and volume ratio, applied in the field of precursor preparation, can solve the problems of poor spinnability of SiBOC precursor and difficult ceramic products, and achieve excellent spinnability and impregnation, excellent high temperature stability, high temperature stability excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

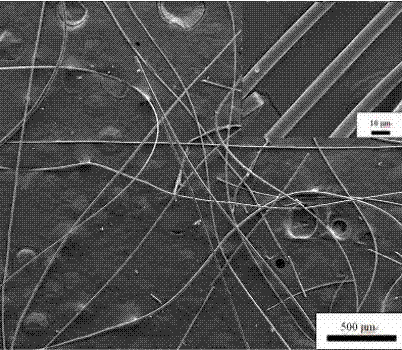

Image

Examples

specific Embodiment approach 1

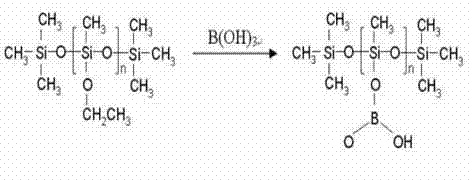

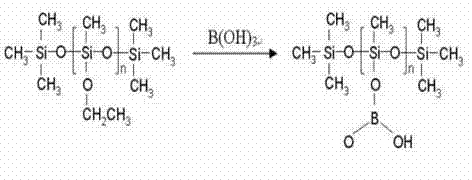

[0008] Specific embodiment 1: The preparation method of the SiBOC precursor in this embodiment is carried out according to the following steps: 1. Hydrogen-containing siloxane and alcohols are mixed according to the volume ratio of 1:1~1.5 to obtain a mixture, and then added to account for the volume percentage of the mixture. 0.05%~1% ethylenediamine, react at room temperature for 2.5~3.5 months to obtain alkoxysiloxane; 2. The alkoxysiloxane and boric acid obtained in step 1 are 1 according to the Si / B molar ratio Mix at a ratio of 0.025 to 1, then add the same alcohols as in step 1 until the boric acid is completely dissolved, and reflux at 64 to 100°C for 2 to 10 hours to obtain the SiBOC precursor; the hydrogen-containing silicon in step 1 Oxane is hydrogen-containing siloxane or hydrogen-containing polysiloxane, hydrogen-containing siloxane is tetramethylcyclotetrasiloxane or tetramethyldihydrogensiloxane, and hydrogen-containing polysiloxane is polymethyl Hydrogen silic...

specific Embodiment approach 2

[0019] Embodiment 2: This embodiment is the same as Embodiment 1 in that in step 1, hydrogen-containing siloxane and alcohols are mixed in a volume ratio of 1:1.2~1.4. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0020] Embodiment 3: This embodiment is the same as Embodiment 1 in that in step 1, hydrogen-containing siloxane and alcohols are mixed in a volume ratio of 1:1.3. Other steps and parameters are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com