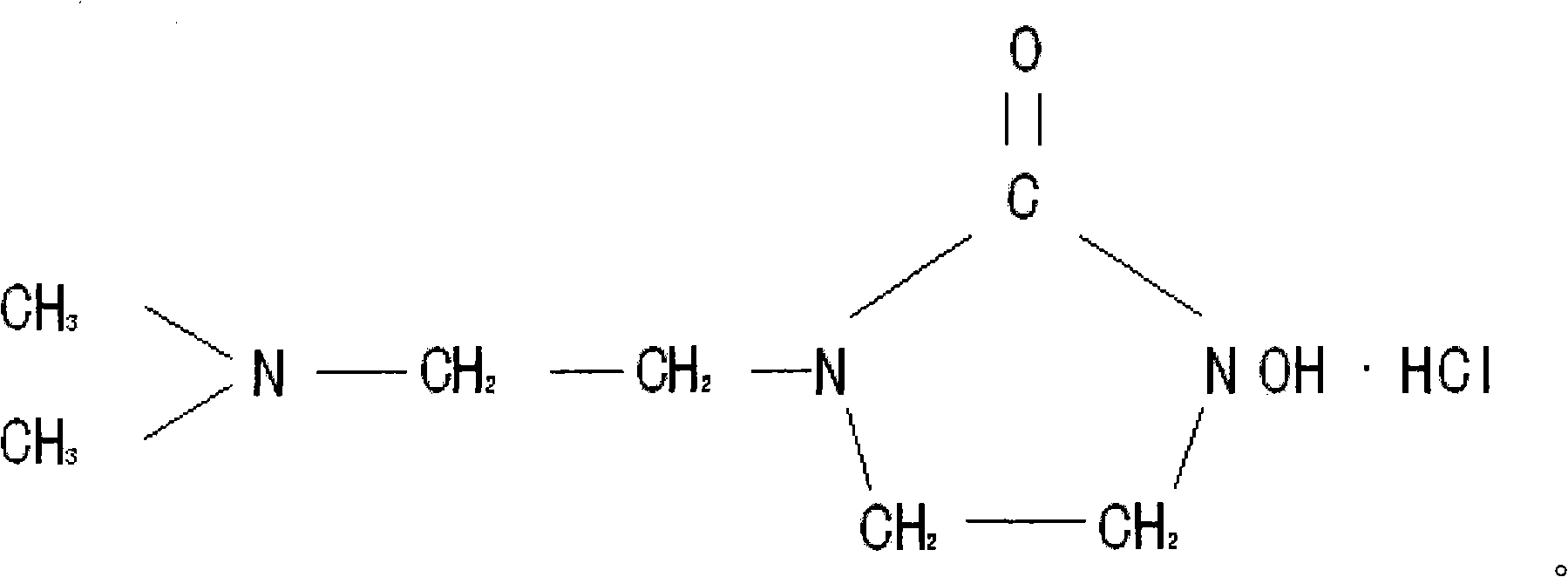

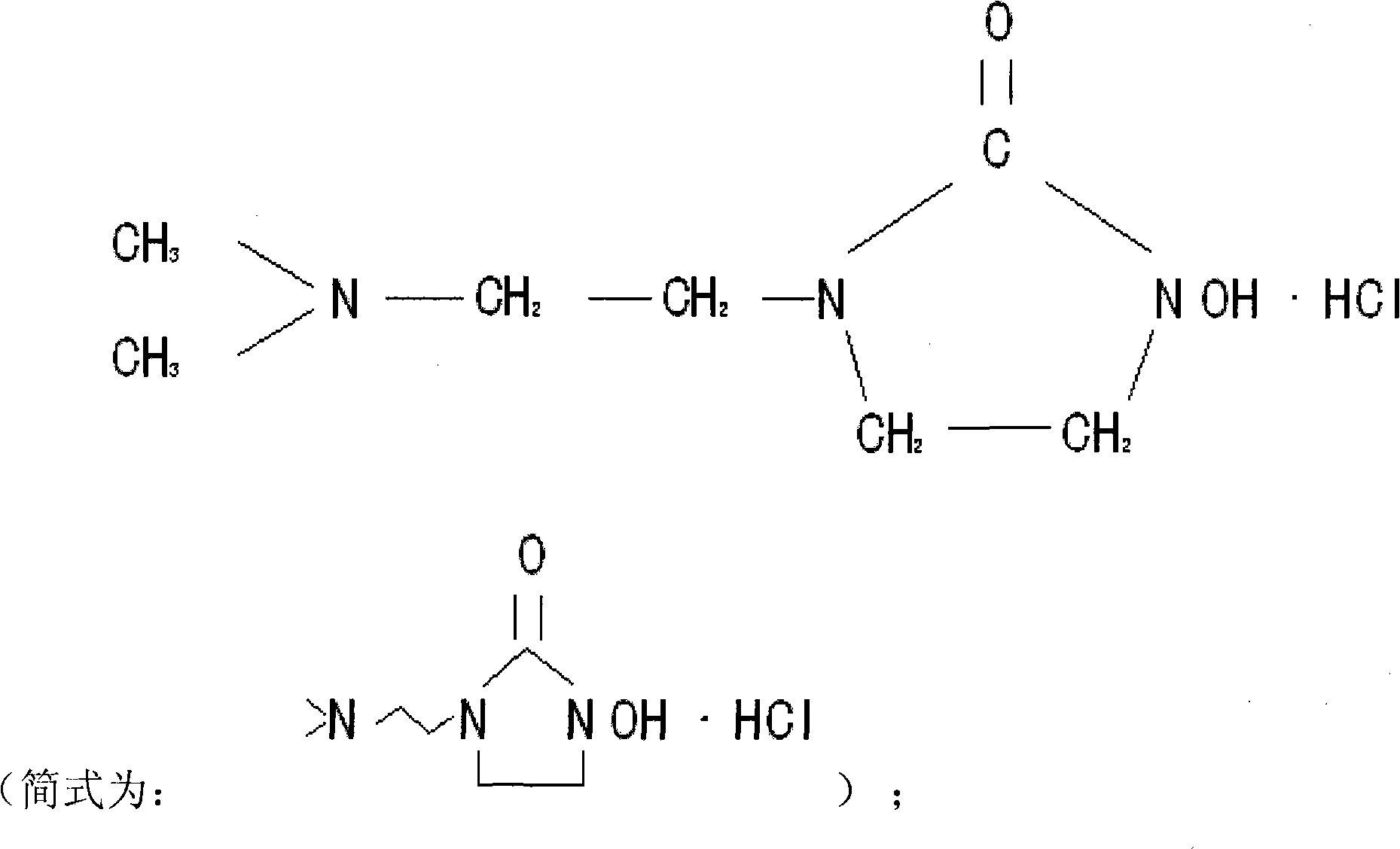

1 (dimethylamino) ethyl, 3-hydroxy-imidazoline hydrochloride and preparation method thereof

A technology of hydroxyimidazolinone hydrochloride and hydroxybenzyl imidazolinone, which is applied in the field of chemistry and can solve problems such as failure to meet environmental protection standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

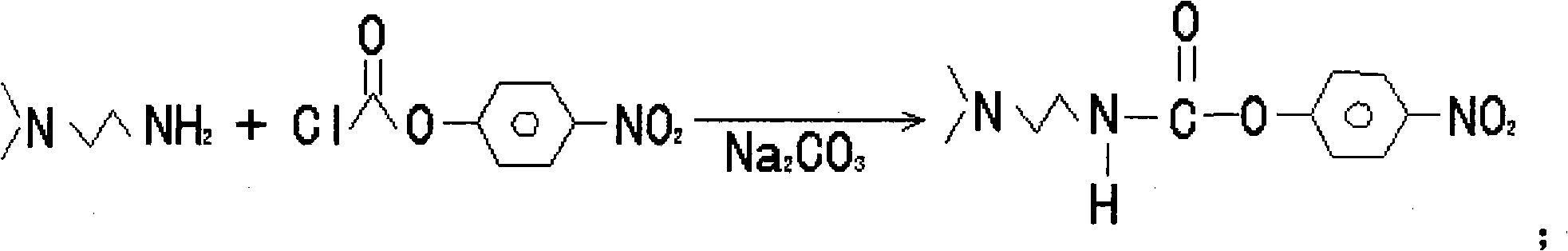

[0018] 1 (dimethylamino) ethyl, the preparation method of 3 hydroxyl imidazolinone hydrochloride is:

[0019] (1) After mixing 88g of dimethylaminoethylamine and 217.3g of p-nitrophenol chloroformate, drop into a 500ml spherical bottle, add 70ml of a mass concentration of 20% sodium carbonate solution, and react at 25°C After 4 hours, add 65ml of toluene, transfer it to a separatory funnel, and let it stand for 10 minutes at 10°C to separate the upper oil layer. After mixing the upper oil layer with 124g of benzyl hydroxylamine, add 85ml of it with a mass concentration of 20 % sodium carbonate solution, placed in a 500ml spherical bottle, reacted for 2 hours at 45°C, cooled to 20°C, added a 15% sodium hydroxide solution to adjust the pH value, adjusted to pH=11, and then Stand still for half an hour at 0°C, then separate the upper oil layer, transfer the separated upper oil layer into a vacuum film rotary evaporator, vacuum degree 0.09Mpa, and distill at a temperature of 50°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com