Filter element and filter unit

A technology of filter material and single fiber, which is applied in the field of filter material and filter unit, can solve the problems of not specifying the specific value, clogging air permeability, reducing filter material, etc., so as to improve deodorization, dust holding function, and washing reproducibility excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

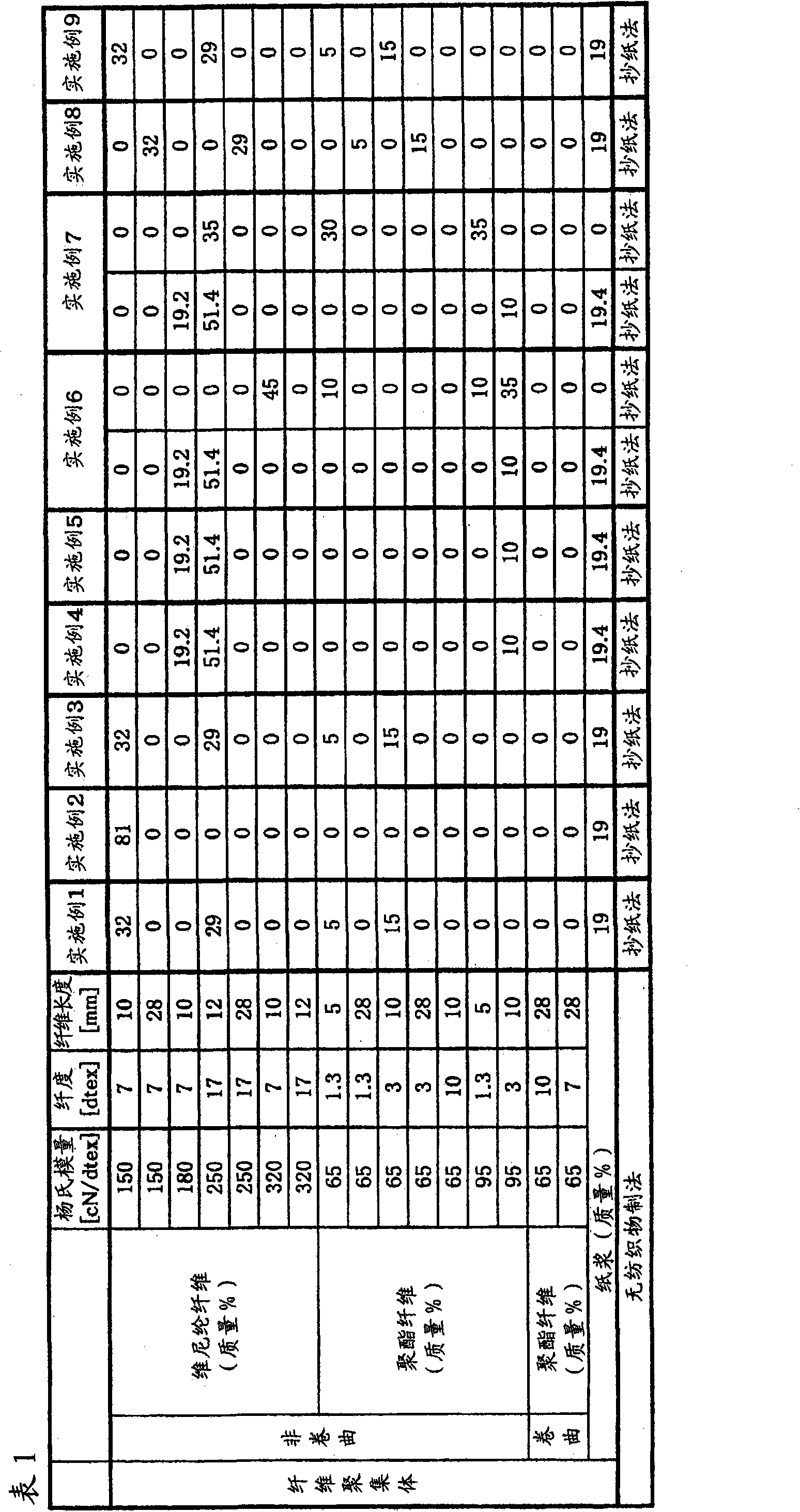

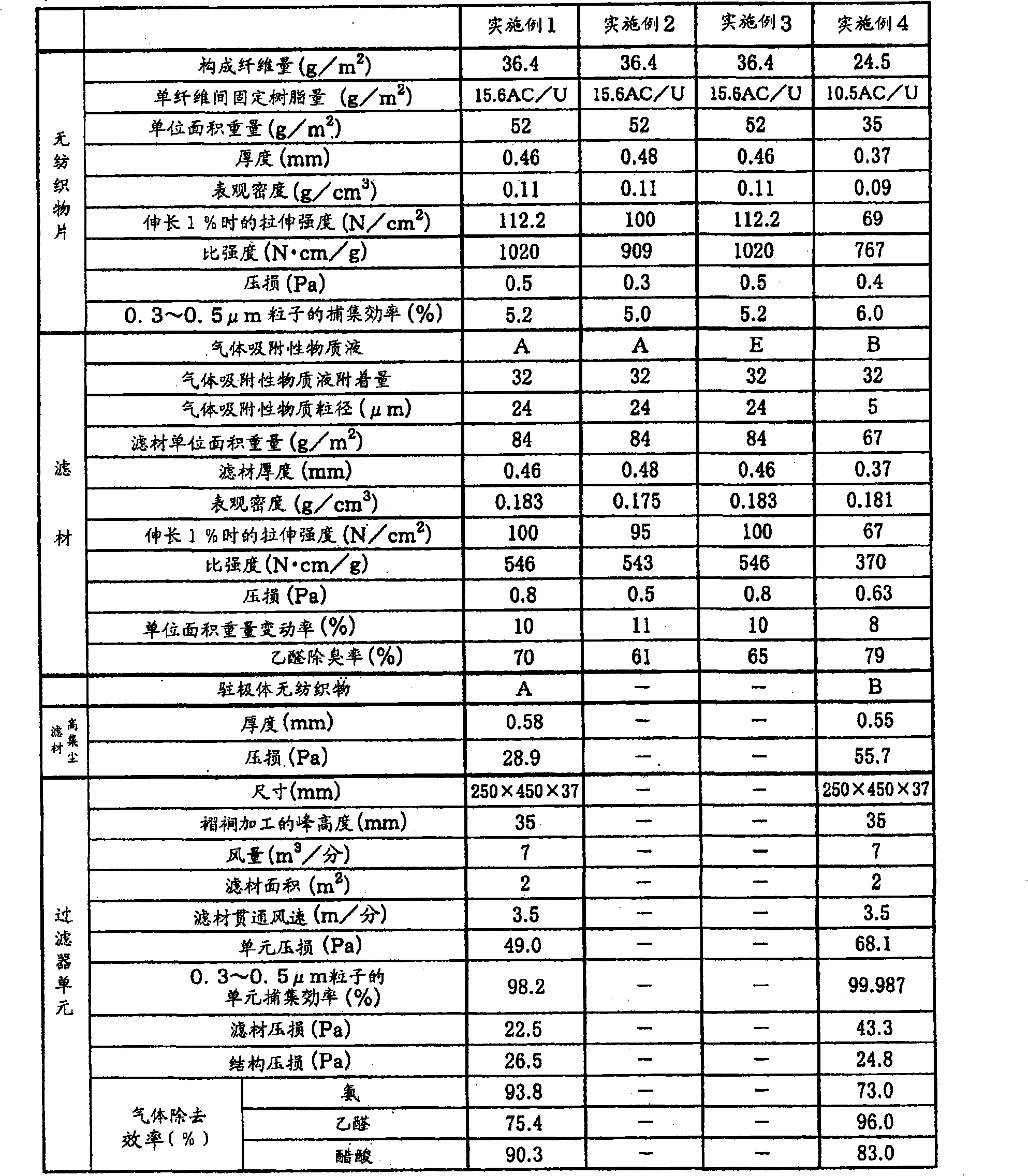

[0170] Using the wet papermaking method of the inclined needle method, the non-crimped vinylon fiber ((a) Young's modulus 150cN / dtex, fineness 7dtex, fiber length 10mm accounts for 32% by mass, (b) Young's modulus 250cN / dtex, fineness 17dtex, fiber length 12mm accounts for 29% by mass)), non-crimp polyester fiber ((a) Young's modulus 65cN / dtex, fineness 3dtex, fiber length 10mm accounts for 15% by mass, (b ) Fibers with a Young's modulus of 65 cN / dtex, a fineness of 1.3 dtex, and a fiber length of 5 mm accounted for 5% by mass, ) and pulp (19% by mass), and the weight per unit area was 36.4 g / m 2 of fiber aggregates. Then, this fiber aggregate was impregnated with a resin in which a styrene-acrylic polymer (glass transition temperature Tg: 30°C, film-forming temperature: 45°C) and a urethane polymer were mixed in a weight ratio of 3:1. After being immersed in a liquid with a liquid-solid content of 30%, the single fibers are fixed by drying and heat treatment, and the weight...

Embodiment 2

[0177] Production of non-crimped vinylon fiber (Young's modulus 150cN / dtex, fineness 7dtex, fiber length 10mm accounting for 81% by mass) and pulp (19% by mass) per unit area using the wet papermaking method of the oblique needle method The weight is 36.4g / m 2 of fiber aggregates. Then, this fiber aggregate is impregnated with a resin liquid solid obtained by mixing a styrene-acrylic polymer (glass transition temperature Tg 30°C, film-forming temperature 45°C) and a urethane polymer in a weight ratio of 3:1. After being immersed in a liquid with a composition of 30%, the single fibers are fixed by drying and heat treatment, and the weight per unit area is 52g / m 2 , thickness 0.48mm, apparent density 0.11g / cm 3 , a non-woven fabric sheet with a pressure loss of 0.3Pa and a specific strength of 909N·cm / g. Since the non-woven fabric sheet has only one kind of non-crimped vinylon fiber, no dense structure appears.

[0178] The fixed solid content on the non-woven fabric sheet ...

Embodiment 3

[0180] The gas-absorbing substance was changed to E liquid containing dodecanedioic acid dihydrazide which is insoluble in water, and the filter material was prepared by the same method as in Example 1 except that it was washed twice with water and dried for evaluation. Acetaldehyde removal rate. As a result, although the initial value of the acetaldehyde removal rate was 65%, it decreased to 62% after washing with water once, and decreased to 58% after washing with water twice, but a high removal rate was confirmed. Since dodecanedioic acid dihydrazide is poorly soluble in water, a high removal rate was confirmed even after washing with water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com