Method for preparing double-layer bionic cartilage tissue engineering scaffold

A cartilage tissue and double-layer technology, which is applied in the field of scaffold preparation for double-layer bionic cartilage tissue engineering, can solve the problems of low bionic degree and complicated process, and achieve the effect of good mechanical properties, thin thickness, and clinical use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

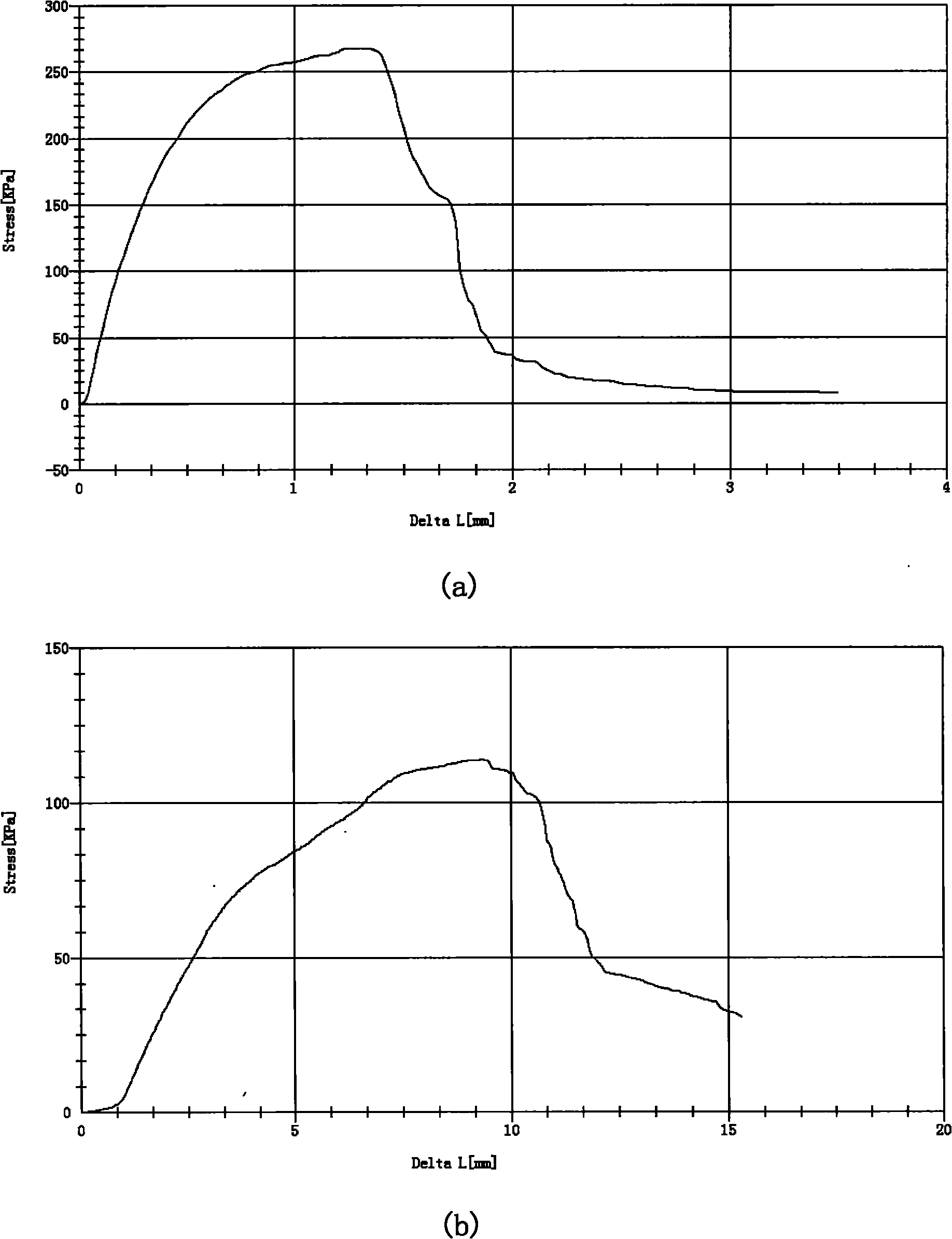

[0030] This embodiment includes the following steps:

[0031] 1. Dissolve polylactic acid PLA in 1,4 epoxyhexane and stir for 24 hours to obtain a 7.4% polylactic acid PLA solution. Take the obtained solution and add it to a mold, and freeze it in a -20°C refrigerator for 4 hours to obtain a substrate;

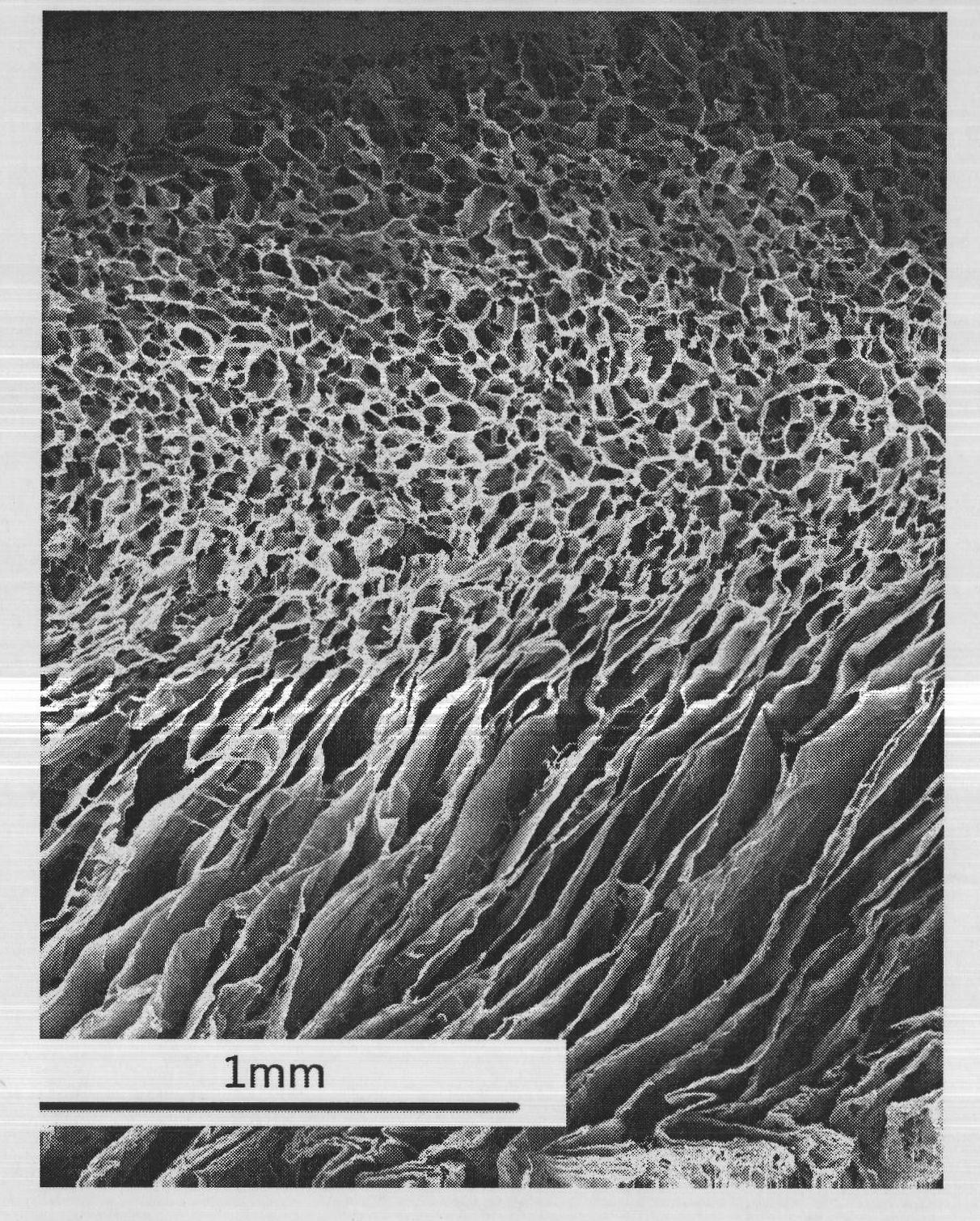

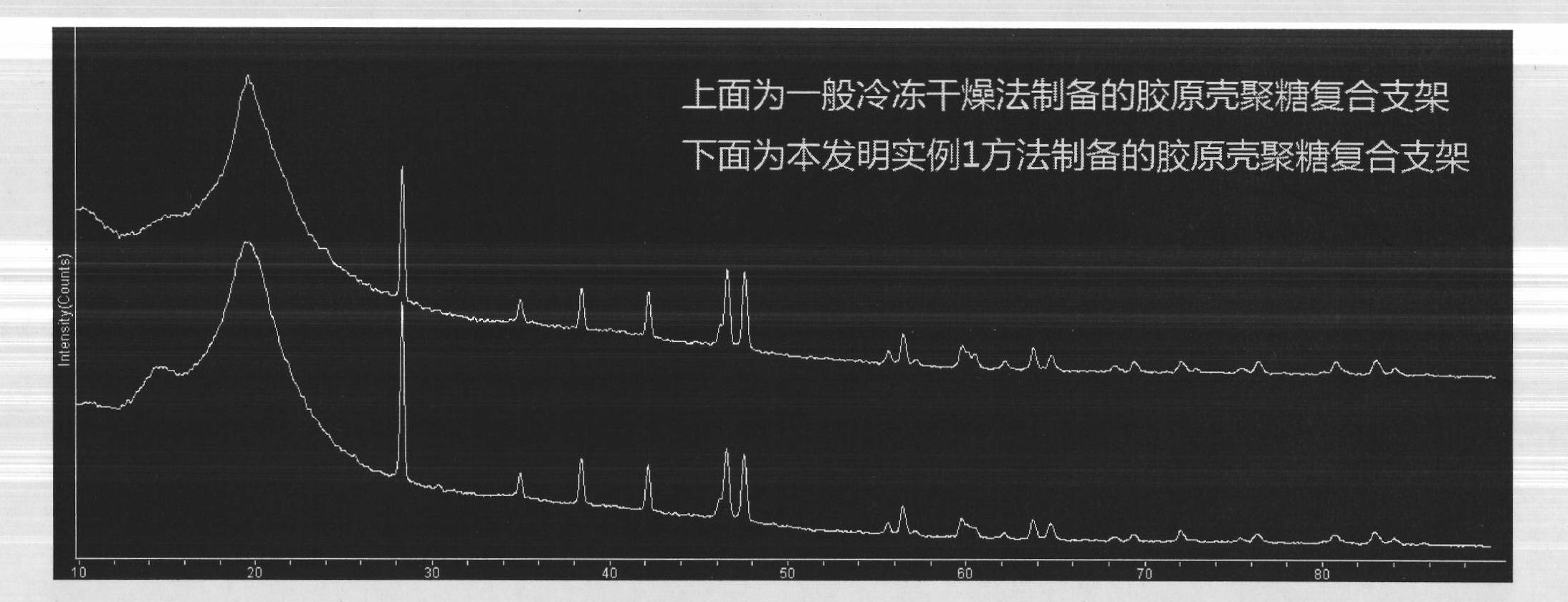

[0032] Two, in 2% acetic acid aqueous solution, chitosan and collagen are added together in the ratio of 2% acetic acid aqueous solution by mass ratio 20: 1, the ratio of added chitosan and collagen mixture and 2% acetic acid aqueous solution is : 2.1g: 100ml, pour the obtained composite solution onto the surface of the substrate obtained in step 1, the pouring thickness is 2.5mm, pre-freeze at -20°C for 6h, then freeze-dry at -50°C and 80Pa for 48h, The substrate and the double-layer biomimetic cartilage scaffold with a thickness of 2.5 mm on the surface of the substrate are formed;

[0033] 3. After molding, soak the double-layer biomimetic cartilage scaffold with 5% NaOH s...

Embodiment 2

[0038] This embodiment includes the following steps:

[0039] 1. Take pure 1,4 epoxy hexacycline and add it to the mold, put the mold into liquid nitrogen to freeze the 1,4 epoxy hexacyclic ring into a solid state for 10 minutes, put the frozen sample in a -20°C refrigerator for 1 hour , get the substrate;

[0040]Two, in 1.5% acetic acid aqueous solution, chitosan and collagen are added together in the ratio of 1.5% acetic acid aqueous solution by mass ratio 20: 1, the ratio of added chitosan and collagen mixture and 1.5% acetic acid aqueous solution is : 1.5g: 100ml, pour the obtained composite solution onto the surface of the substrate obtained in step 1, the pouring thickness is 2.5mm, pre-freeze at -20°C for 6h, then freeze-dry at -50°C and 80Pa for 48h, The substrate and the double-layer biomimetic cartilage scaffold with a thickness of 2.5 mm on the surface of the substrate are formed;

[0041] 3. After forming, the double-layer biomimetic cartilage scaffold on the su...

Embodiment 3

[0044] This embodiment includes the following steps:

[0045] 1. Dissolve polylactic acid PLA in 1,4 epoxyhexane and stir for 48 hours to obtain a 6.4% polylactic acid PLA solution. Add bone powder equivalent to polylactic acid PLA to the polylactic acid PLA solution and stir for 48 hours to mix evenly. Take The obtained solution was put into a mold, and placed in a refrigerator at -20°C for 4 hours to obtain a substrate;

[0046] 2. In 2% acetic acid aqueous solution, add chitosan or collagen, or add chitosan and collagen together in 2% acetic acid aqueous solution in any proportion, the added chitosan or collagen or chitosan and collagen The ratio of the mixture to 2% acetic acid aqueous solution is: 3.5g: 100ml, pour the resulting composite solution onto the surface of the substrate obtained in step 1, the pouring thickness is 3mm, pre-freeze at -20°C for 4h, and then Freeze-dry at -50℃, 90Pa for 48 hours, and form the substrate and the double-layer biomimetic cartilage sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com