Anti-slip glass, multifunctional anti-slip glass floor and preparation methods thereof

A multi-functional, glass technology, applied in chemical instruments and methods, layered products, construction, etc., can solve problems such as short timeliness, scattered debris, and reduced bonding strength, and achieve conditions that are easy to achieve, simple to prepare, and easy to manufacture. simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

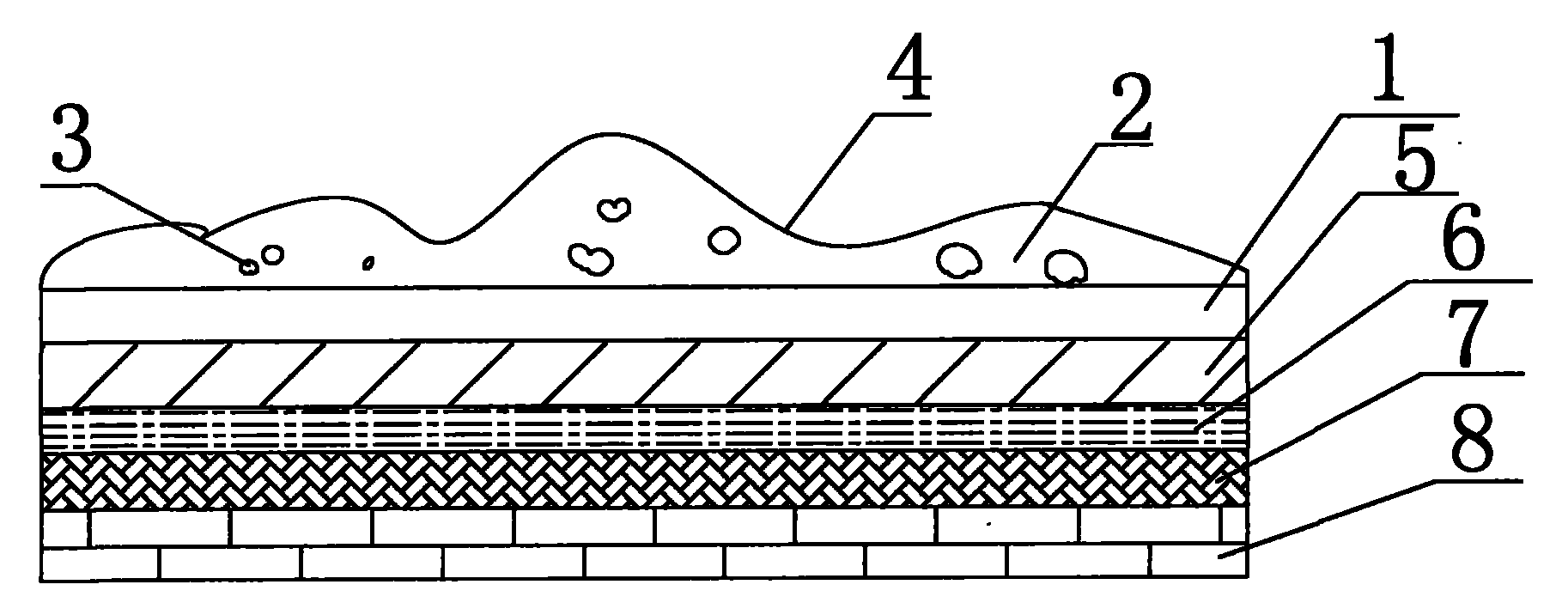

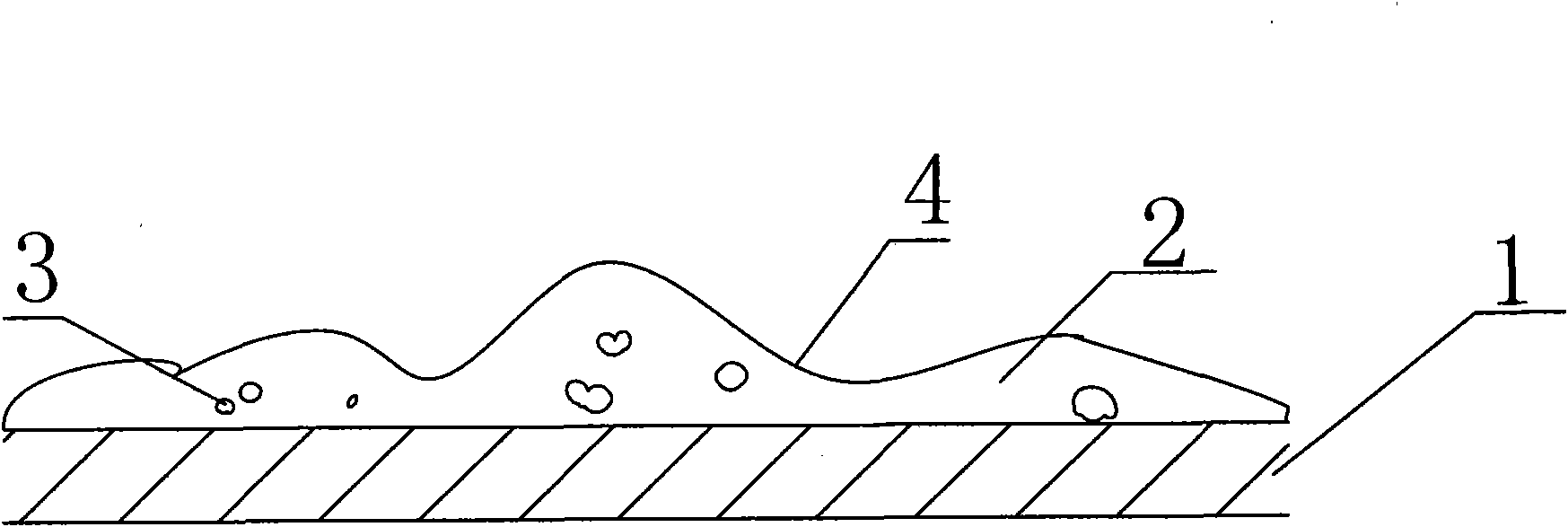

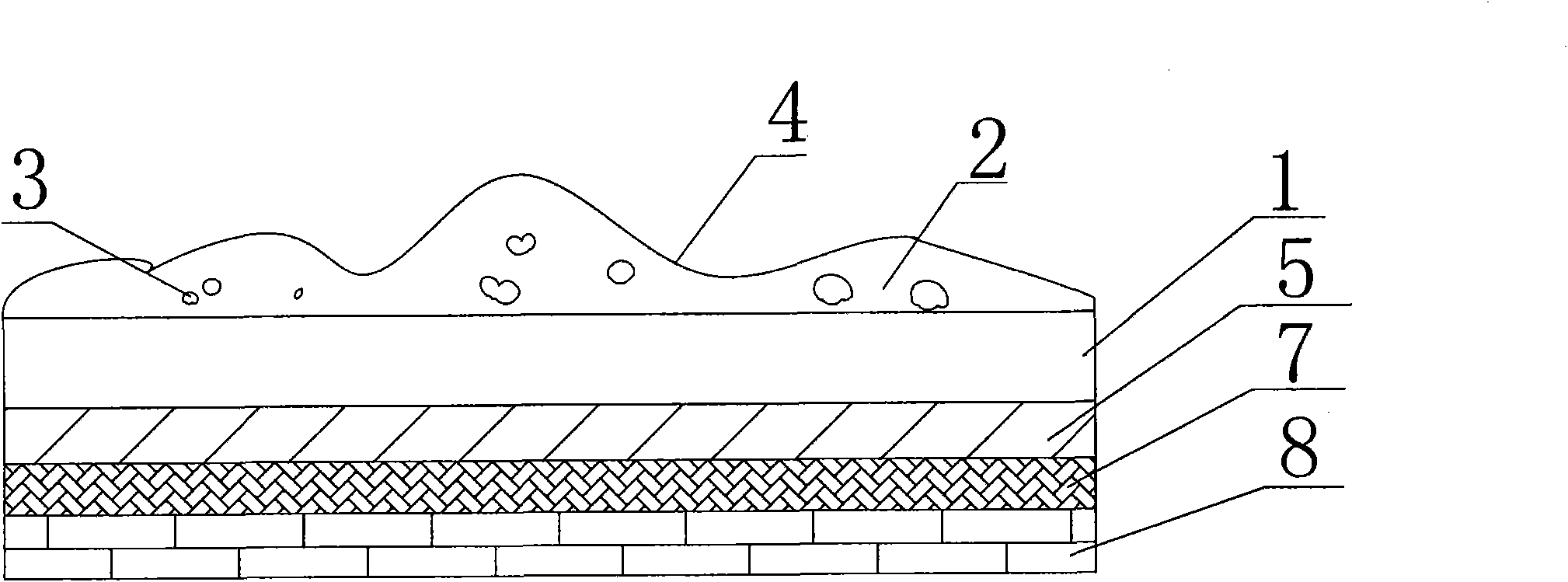

[0026] As shown in Figure 1, the anti-slip glass of the present invention includes a glass substrate 1 and an anti-slip layer 4 fixed on the upper surface of the glass substrate 1. The anti-slip layer 4 is a resin film 2 formed by screen printing and curing. In the anti-slip layer 4, resin The film 2 is a polyurethane resin film with a weight percentage of 40%, and the resin film 2 is evenly coated with anti-skid pellets mixed with 20% by weight of polypropylene resin particles and 20% by weight of silicon carbide 3. The particle size of the non-slip granular material 3 is 40 mesh.

[0027] The preparation method of the above-mentioned anti-slip glass is to wet the anti-slip pellets 3 with resin solution in advance and mix them evenly, then screen-print the resin film layer with a thickness of 100um-1.2mm on the glass substrate 1, and then send it into a low-temperature drying furnace. Take it out after drying and heating at 90° C. for 25 minutes, thereby forming a non-slip gl...

Embodiment 2

[0029] As shown in Figure 1, the anti-slip glass of the present invention includes a glass substrate 1 and an anti-slip layer 4 fixed on the upper surface of the glass substrate 1. The anti-slip layer 4 is a resin film 2 formed by screen printing and curing. In the anti-slip layer 4, resin Film 2 is a polyurethane resin film with a weight percentage of 60%. The resin film 2 is evenly coated with anti-slip pellets 3 mixed with 35% by weight of polyurethane resin particles and 35% by weight of aluminum oxide. , The particle diameter of anti-skid pellet 3 is 100 mesh.

[0030] The preparation method of the above-mentioned anti-slip glass is to wet the anti-slip pellets 3 with resin solution in advance and mix them evenly, then screen-print the resin film layer with a thickness of 100um-1.2mm on the glass substrate 1, and then send it into a low-temperature drying furnace. Take it out after drying and heating at 130° C. for 30 minutes, thereby forming an anti-slip glass with an an...

Embodiment 3

[0032] As shown in Figure 1, the anti-slip glass of the present invention includes a glass substrate 1 and an anti-slip layer 4 fixed on the upper surface of the glass substrate 1. The anti-slip layer 4 is a resin film 2 formed by screen printing and curing. In the anti-slip layer 4, resin The film 2 is a polyurethane resin film, and its weight percentage is 80%. The resin film 2 is evenly coated with anti-slip pellets 3 mixed with 50% by weight of polyurethane resin particles and 50% by weight of aluminum oxide. , The particle size of anti-slip pellets 3 is 150 mesh.

[0033] The preparation method of the above-mentioned anti-slip glass is to wet the anti-slip pellets 3 with resin solution in advance and mix them evenly, then screen-print the resin film layer with a thickness of 100um-1.2mm on the glass substrate 1, and then send it into a low-temperature drying furnace. Take it out after drying and heating at 150° C. for 35 minutes, thereby forming an anti-slip glass with an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com