Polyamide composite material for vehicle induction manifold and preparation method thereof

A technology for composite materials and intake manifolds, which is applied in the field of polyamide composite materials for vehicle intake manifolds and its preparation, can solve the problems of easy oxidative degradation and poor thermal fusion performance, and improve long-term heat resistance and heat resistance. Fusion performance, improve heat fusion performance, and facilitate the effect of heat fusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

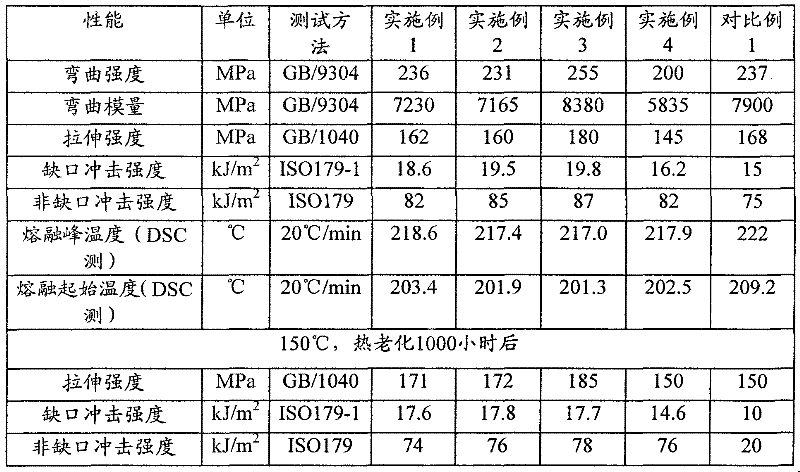

Examples

Embodiment 1

[0034] The raw material ratio is as follows:

[0035] PA6: (produced by Guangdong Xinhui Meida Nylon Co., Ltd., model M12400, relative viscosity 2.4) 61.8kg

[0036] PA1010 (Shanghai celluloid nylon, type 11; viscosity number 99-116, melting point 204°C) 4kg

[0037] PE-g-MAH (Ningbo Nengzhiguang New Material Technology Co., Ltd., model: (PE)-MC218) 3kg

[0038] Heat stabilizer: (composition: a mixture of copper iodide salt, halogen compound and stearate; German Brüggemann Chemical Company, model: H3374) 0.4kg

[0039] Ultra-high molecular weight silicone powder (Dow Corning Company, model DC-500 / 800, average molecular weight: 670,000-700,000) 0.8kg

[0040] Alkali-free glass fiber (Chongqing International Composite Materials Co., Ltd., model ECS3014B) 30kg treated with silane coupling agent on the surface

[0041] The preparation method is as follows:

[0042] First, PA6, PA1010, compatibilizer PE-g-MAH, lubricant ultra-high molecular weight silicone powder, stabilizer co...

Embodiment 2

[0045] The raw material ratio is as follows:

[0046] PA6 (Taiwan Jisheng Company, model: TP4205, relative viscosity 2.4) 61.5kg

[0047] PA12 (Japan Ube, model: 3020U, melting point 180°C) 4kg SEBS-g-GMA (American Kraton thermoplastic elastomer, model: FG1901) 3kg

[0048] Heat Stabilizer: Composition: Copper iodide salt, a mixture of halogen compounds and stearates; Swiss Ciba Specialty Chemical Co., Ltd., model: PolyAd HS 03: 0.3kg

[0049]Heat stabilizer: (tris(2,4-di-tert-butylphenyl) phosphite; Swiss Ciba Fine Chemicals, model: 168) 0.2kg

[0050] Heat stabilizer: (N,N'-bis-[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl]hexamethylenediamine; Swiss Ciba Fine Chemicals, model: 1098) 0.2kg

[0051] Lubricant: (polyethylene wax modified by metallocene treatment; Clariant Chemical Co., Ltd., model: PEMA4221) 0.8kg

[0052] Alkali-free glass fiber whose surface is treated with silane coupling agent: (Chongqing International Composite Materials Co., Ltd., model ECS5301HP) 3...

Embodiment 3

[0055] The raw material ratio is as follows:

[0056] PA6 (Taiwan Jisheng Company, model: TP4205, relative viscosity 2.45) 47.8kg

[0057] PA12 (Japan Ube: Model: 3020U, melting point 180°C) 8kg

[0058] SEBS-g-GMA (Kraton thermoplastic elastomer, model: FG1901) 2kg

[0059] Heat stabilizer: composition: copper iodide salt, a mixture of halogen compounds and stearates;

[0060] Swiss Ciba Specialty Chemical Co., Ltd., model: PolyAd HS 02) 0.2kg

[0061] Heat stabilizer: (tris(2,4-di-tert-butylphenyl) phosphite;

[0062] Swiss Ciba Fine Chemicals, Model: 168) 0.6kg

[0063] Heat stabilizer: (N, N'-bis-[3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionyl] hexamethylenediamine; Swiss Ciba Fine Chemicals, model: 1098) 0.6 kg

[0064] Lubricant: (metallocene modified polyethylene wax; Clariant Chemical Co., Ltd., model: PEMA 4221) 0.8kg

[0065] Alkali-free glass fiber whose surface is treated with silane coupling agent: (Chongqing International Composite Materials Co., Ltd., mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com