Polyamide composite material and its preparation method and application

A composite material and polyamide technology, which is applied to the special polyamide composite material for cable guide pulleys of power grid engineering and the field of preparation thereof, can solve the problems of not fully satisfying the cable guide pulley, difficult to recycle, difficult to recycle, etc. Lightweight, short cycle times and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

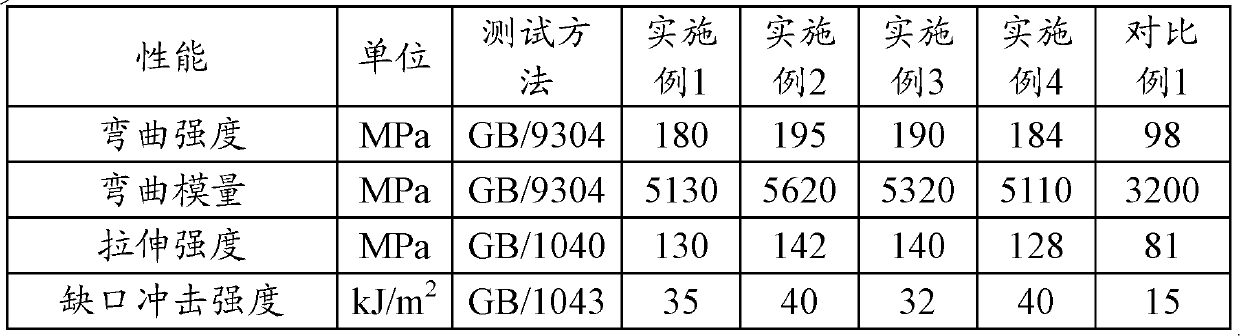

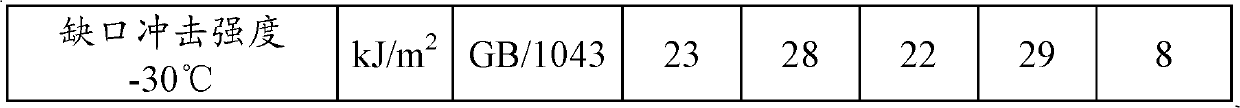

Examples

Embodiment 1

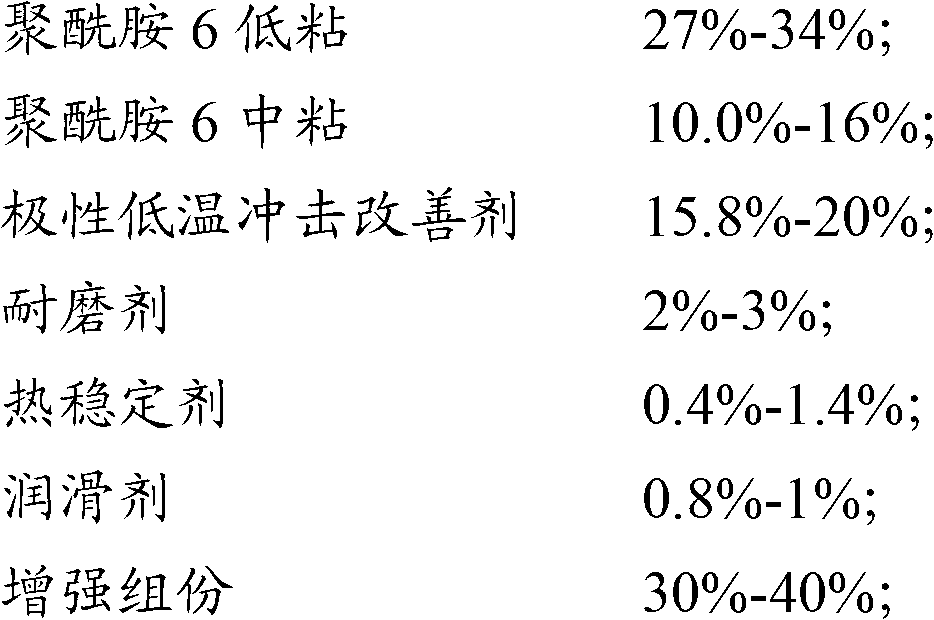

[0041] Use the following weights of ingredients:

[0042] PA6 low viscosity (produced by Guangdong Xinhui Meida Nylon Co., Ltd., model M12400, relative viscosity 2.4) 29kg;

[0043] PA6 medium viscosity (produced by Yueyang Baling Petrochemical Chemical Fiber Co., Ltd., model YH800, relative viscosity 2.8) 5.8kg;

[0044] POE-g-MAH (Ningbo Nengzhiguang New Material Technology Co., Ltd., model: N410) 5kg;

[0045]POE-g-MAH (Ningbo Nengzhiguang New Material Technology Co., Ltd., model: N409) 12kg;

[0046] Polytetrafluoroethylene (Lanpoly Chemical Company, model FW4300, average particle size 12um) 2kg;

[0047] Cuprous iodide composite stabilizer (composition: the mixture of cuprous iodide salt, halogen compound and stearate; German Brüggemann Chemical Company, model: H3373, wherein, the weight content of copper is 100ppm) 0.4kg;

[0048] Ultra-high molecular weight silicone powder (Dow Corning Company, model DC-500 / 800, 680,000 average molecular weight) 0.8kg;

[0049] 35kg...

Embodiment 2

[0052] Use the following weights of ingredients:

[0053] PA6 low viscosity (Taiwan Jisheng Company, model: TP4205, relative viscosity 2.45) 27kg;

[0054] PA6 medium viscosity (produced by Zhejiang Huajian Nylon Co., Ltd., model: M52800, relative viscosity 2.8) 12kg;

[0055] SEBS-g-GMA (Kraton thermoplastic elastomer, model: FG1901) 17kg;

[0056] Molybdenum disulfide (Dow Corning, model: Molykote P1000) 2.5kg;

[0057] Cuprous iodide composite stabilizer (leading chemical composition in the United States: a mixture of copper salt (cuprous iodide), halogen compound (potassium iodide) and zinc stearate, wherein the mass percentage of copper is 3.0%) 0.3 kg;

[0058] Heat stabilizer (tris(2,4-di-tert-butylphenyl) phosphite; Swiss Ciba Fine Chemicals, model: 168) 0.2kg;

[0059] Heat stabilizer (N,N'-bis-[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl]hexamethylenediamine; Swiss Ciba Fine Chemicals, model: 1098) 0.2kg;

[0060] Lubricant (polyethylene wax modified by metal...

Embodiment 3

[0064] Use the following weights of ingredients:

[0065] PA6 low viscosity (Taiwan Jisheng Company, model: TP4205, relative viscosity 2.45) 34kg;

[0066] PA6 medium viscosity (produced by Zhejiang Huajian Nylon Co., Ltd., model: M52800, relative viscosity 2.8) 16kg;

[0067] SEBS-g-GMA (Craton thermoplastic elastomer, model: FG1901) 8kg;

[0068] EPDM-g-MAH (Shanghai Rizhisheng New Technology Development Company, model: CMG-9802) 7.8kg;

[0069] Molybdenum disulfide (Dow Corning, model: Molykote P 1000) 1.0kg;

[0070] Polytetrafluoroethylene (produced by Lanpoly Chemical Company, model FW4300, average particle size 12um) 1.0kg;

[0071] Cuprous iodide composite stabilizer (leading chemical composition in the United States: a mixture of copper salt (cuprous iodide), halogen compound (potassium iodide) and magnesium stearate, wherein the mass percentage of copper is 3.0%) 0.2 kg;

[0072] Heat stabilizer (tris(2,4-di-tert-butylphenyl) phosphite; Swiss Ciba Fine Chemicals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com