Nickel-copper alloy rod or profile for high-speed electrified railway in CY state

A technology for electrified railways and copper alloys, applied in the field of nickel-silicon-copper alloy rods or profiles, can solve the problems of high cost and long process flow, achieve high elongation strength, reduce production cost, and reduce the effect of processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

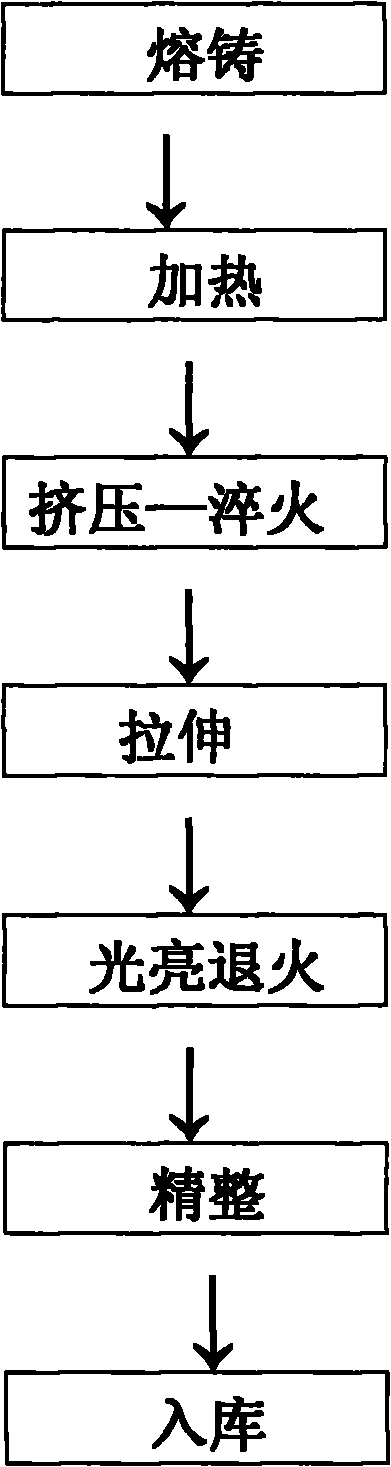

[0017] Processing and manufacturing CuNi2Si alloy profiles of φ24X6000mm in CY state, the process flow adopts:

[0018] Melting and casting: Nickel-silicon-copper alloy material components are weighed according to weight ratio. Ingredients: nickel 1.6-3.4%, silicon 0.15-1.1%, manganese ≤ 1.0%, iron ≤ 0.6% and unavoidable impurities ≤ 0.3%, the balance is Copper is formed together; weighed separately and put into the melting furnace one after another, melted and cast into ingots;

[0019] Heating: use induction heating furnace to heat the ingot, heating temperature: 850~900℃, heating time: 3~6min;

[0020] Extrusion-Quenching: The extruder is used to water-seal the heated ingot and process it into a billet, that is, the die outlet of the extruder is connected to a water tank, so that the extruded billet directly enters the water tank for rapid cooling, which can prevent Oxidation of the surface of the billet, and refinement control of the grains of the alloy structure of the b...

Embodiment 2

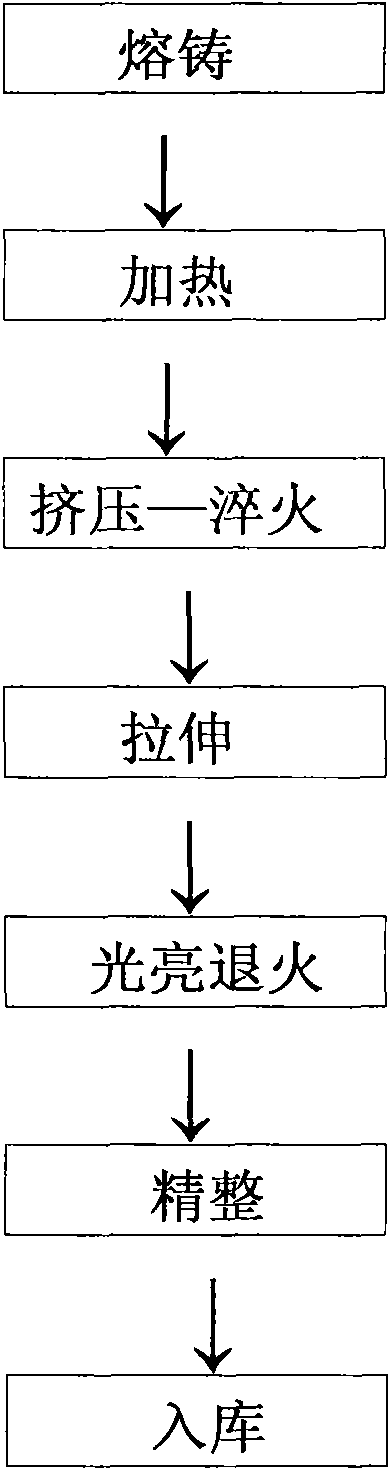

[0026] Processing and manufacturing CuNi2Si alloy rods of φ24X3000mm in CY state, the process flow adopts:

[0027] Melting and casting: Nickel-silicon-copper alloy material components are weighed according to weight ratio. Ingredients: nickel 1.6-3.4%, silicon 0.15-1.1%, manganese ≤ 1.0%, iron ≤ 0.6% and unavoidable impurities ≤ 0.3%, the balance is Copper is weighed and put into the smelting furnace successively to be melted and cast into ingots;

[0028] Heating: use induction heating furnace to heat the ingot, heating temperature: 850~900℃, heating time: 3~6min;

[0029] Extrusion-Quenching: The extruder is used to water-seal the heated ingot and process it into a billet, that is, the die outlet of the extruder is connected to a water tank, so that the extruded billet directly enters the water tank for rapid cooling, which can prevent Oxidation of the surface of the billet, as well as refinement and control of the grain of the billet structure, the extrusion ratio: 26-45;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com