Automatic pretreatment device for total organic carbon in shale and working method

A total organic carbon and automatic technology, which is applied in the field of automatic pretreatment devices for total organic carbon in shale, can solve the problems of time-consuming analysis and testing, labor-intensive, complicated operation procedures, etc., and achieves reduction of pickling and water washing time and The number of times, improve the efficiency of use, improve the effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

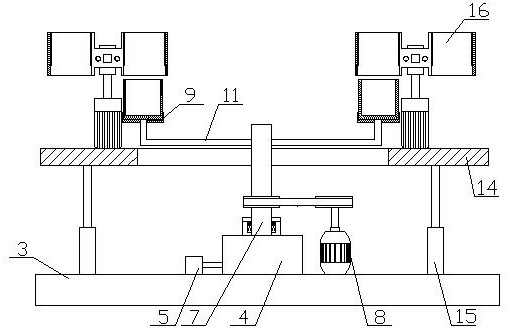

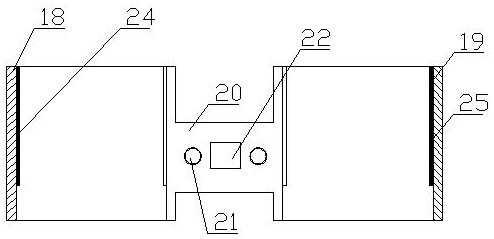

[0053] like Figure 1-8 As shown, the present invention includes a heating oven 1. The heating oven 1 can be, but is not limited to, an electric heating oven with a temperature control function. The electric heating oven belongs to conventional heating equipment in the prior art. Preferably, the heating oven 1 can also use a microwave oven.

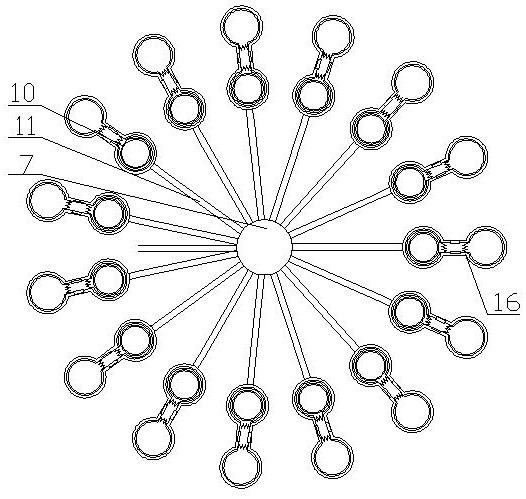

[0054] The heating oven 1 is supported with a removable pre-processing device 2. The pre-processing device 2 includes a base 3. A liquid collecting tank 4 is installed in the center of the base 3, and the top middle of the liquid collecting tank 4 is rotated and installed through a bearing seat 6. There is a liquid collecting main pipe 7, the lower end of the liquid collecting main pipe 7 is open and extends into the liquid collecting tank 4, and the top of the liquid collecting tank 4 is also connected with a vacuum generating device 5.

[0055] A main pipe driving motor 8 is installed on the base 3 to drive the liquid collecting main pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com