Device and method for removing metal plating layer on back of nano-alumina template

A technology of nano-alumina and back metal, which is applied in metal processing equipment, grinding machines, grinding/polishing equipment, etc., and can solve problems such as failure to recycle nano-alumina powder, abrasion of alumina templates, and high labor intensity , to achieve uniform force, improve utilization, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: Removal of the gold coating on the back side of the nano-alumina template

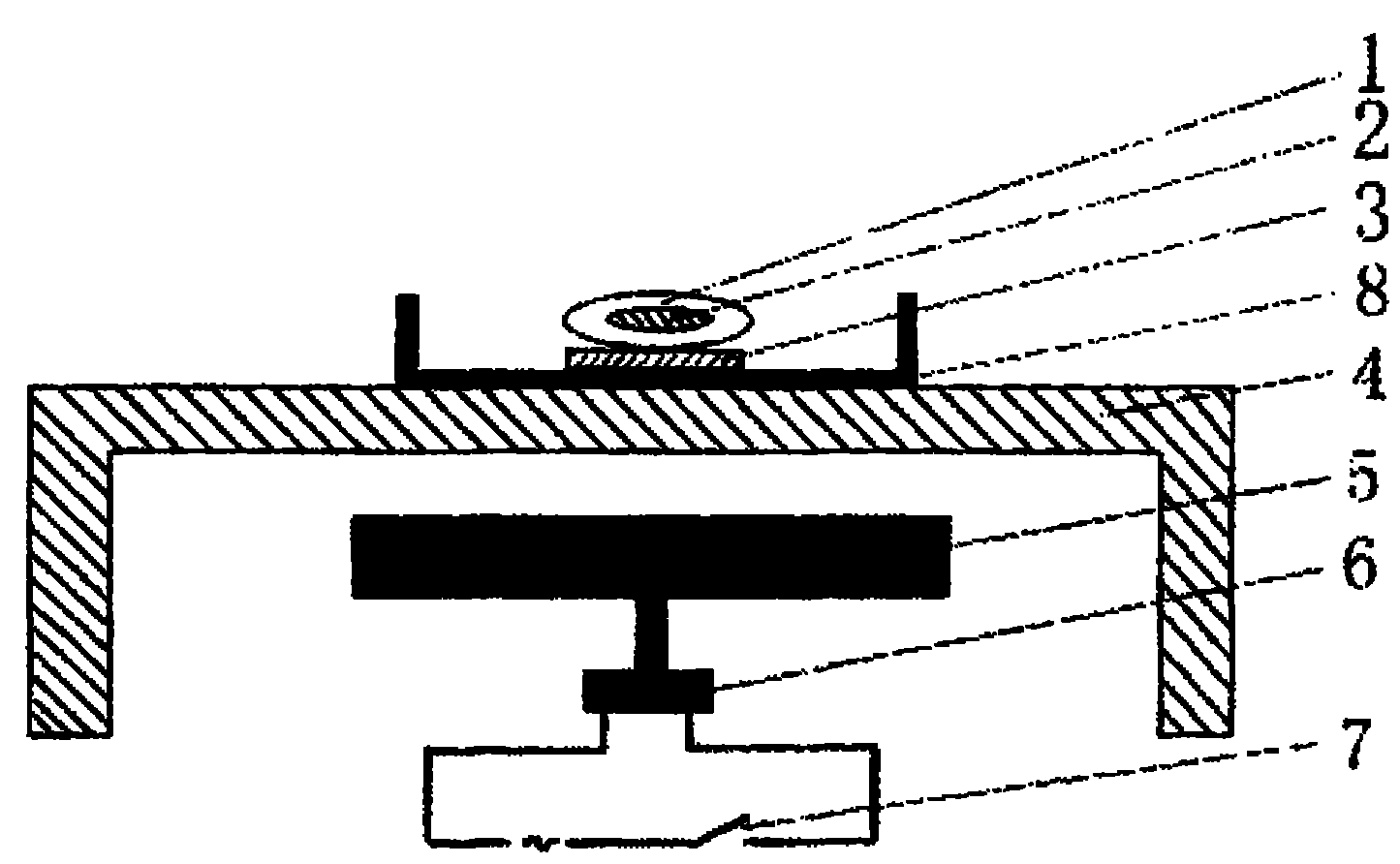

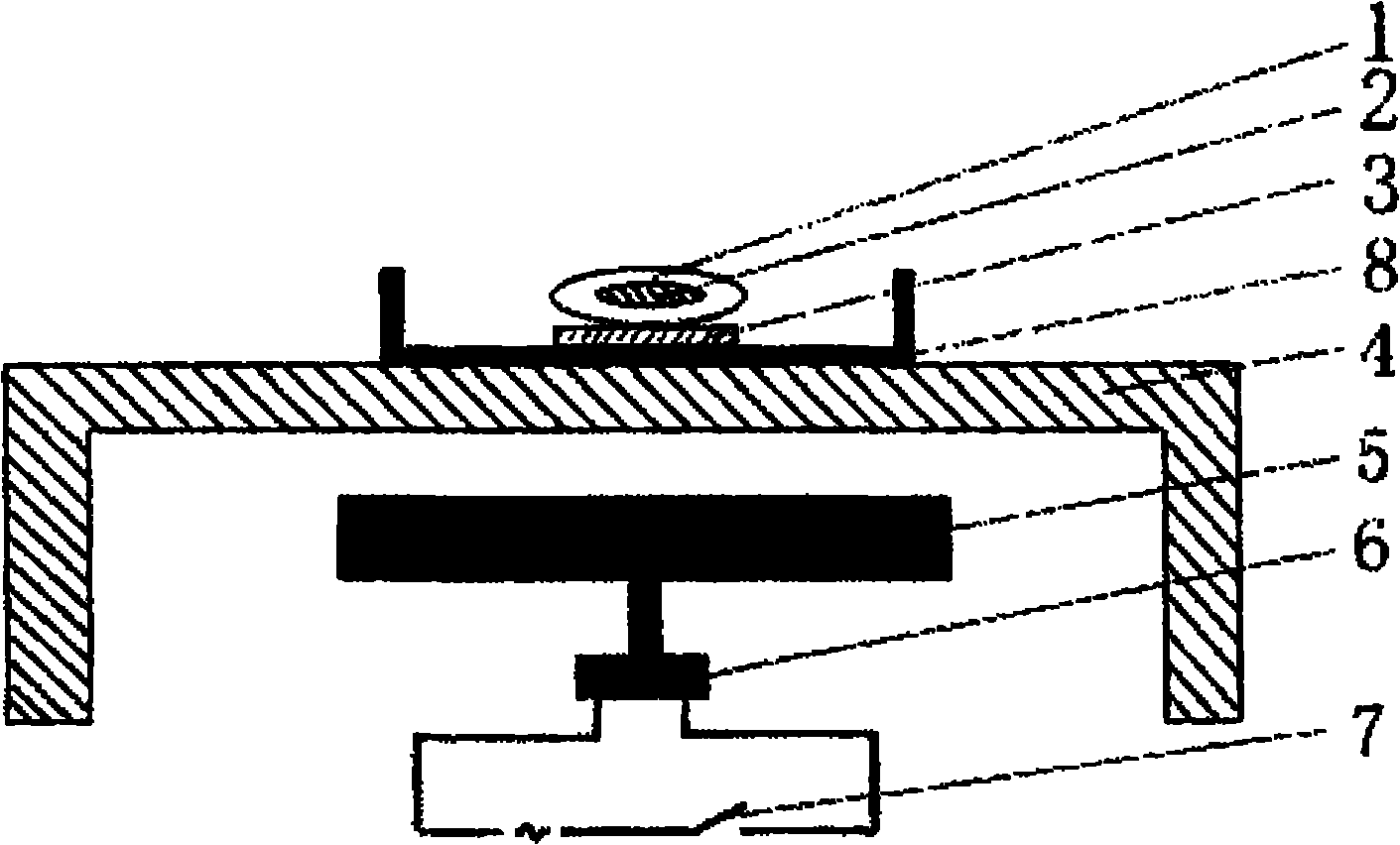

[0016] First, the device for removing the metal coating on the back side of the nano-alumina template is assembled according to the configuration schematic diagram shown in Figure 1: the device includes a magnetic stirrer 2 on the work disk 4, and a speed control switch 7 is housed in the work disk 4. A magnetic stirrer composed of a motor 6 and a bar magnet 5 driven by the motor 6; the magnetic stirrer 2 is wrapped with a 1-5mm thick alcohol cotton 1; the alcohol cotton 1 is a absorbent cotton soaked in alcohol .

[0017] A. Take a piece of nano-alumina template 3 with a diameter of 10mm and a gold coating on the back, and fix the nano-alumina template 3 on the bottom surface center of the magnetic stirrer work plate 4 with the gold coating on the back facing up with double-sided adhesive tape. Sprinkle 0.5g nano-alumina powder on the surface of the gold coating, and gently place...

Embodiment 2

[0022] Embodiment 2: Removal of the silver coating on the back side of the nano-alumina template

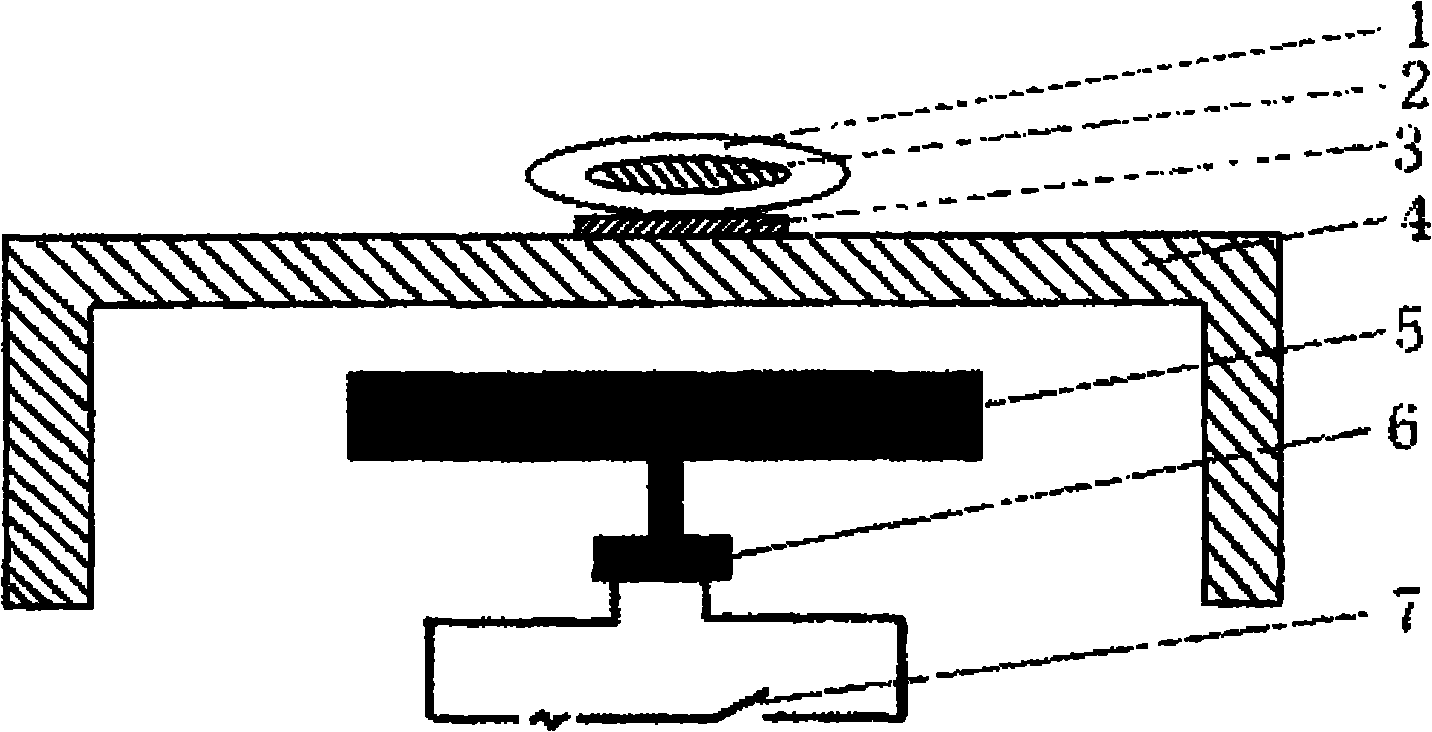

[0023] Using the device shown in Figure 2, a piece of nano-alumina template with a diameter of 10mm and a silver coating on the back is fixed on the bottom surface of a petri dish with double-sided tape facing upwards, and sprinkles on the silver coating. Put 0.5g of nano-alumina powder on it, then place the petri dish on the working plate of the magnetic stirrer, and gently place a magnetic stir bar with a thickness of 3mm on the silver coating with an alcohol cotton wrap; Adjust the speed of the magnetic stirrer to the minimum value before the magnetic stirrer rotates stably, and then slowly increase the speed. After rotating for 30 minutes, it is observed that the silver coating has been completely removed, and the speed of the magnetic stirrer is slowly adjusted. Smallest to smallest, and last to off. Remove the magnetic stir bar and template wrapped in alcohol cotton and re...

Embodiment 3

[0025] Embodiment 3: Removal of the copper coating on the back side of the nano-alumina template

[0026]Using the device shown in Figure 2, a piece of nano-alumina template with a diameter of 10mm and a copper plating layer on the back is fixed on the bottom surface of a petri dish with double-sided tape facing upwards, and on the copper plating layer. Sprinkle the nano-alumina powder of 0.5g, then this petri dish is placed on the work plate of magnetic stirrer, and the magnetic stir bar that the thickness of an alcohol cotton wrapping layer is 3mm is placed gently on the copper plating layer; Before starting the magnetic stirrer, adjust its speed to the minimum. When the magnetic stirrer rotates stably, slowly increase the speed. After 30 minutes of rotation, it is observed that the copper coating has been completely removed. Slowly adjust the speed of the magnetic stirrer. to minimum, and finally off. Remove the magnetic stir bar and template wrapped in alcohol cotton and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com