Method for implementing airborne variable pressure hydraulic energy system

A technology of hydraulic energy and variable pressure, which is applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, mechanical equipment, etc. Problems such as large amount of heat generation and pollution generated by the system, to achieve the effects of reducing heat generation and pollutant generation, improving energy utilization rate, and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of the accompanying drawings.

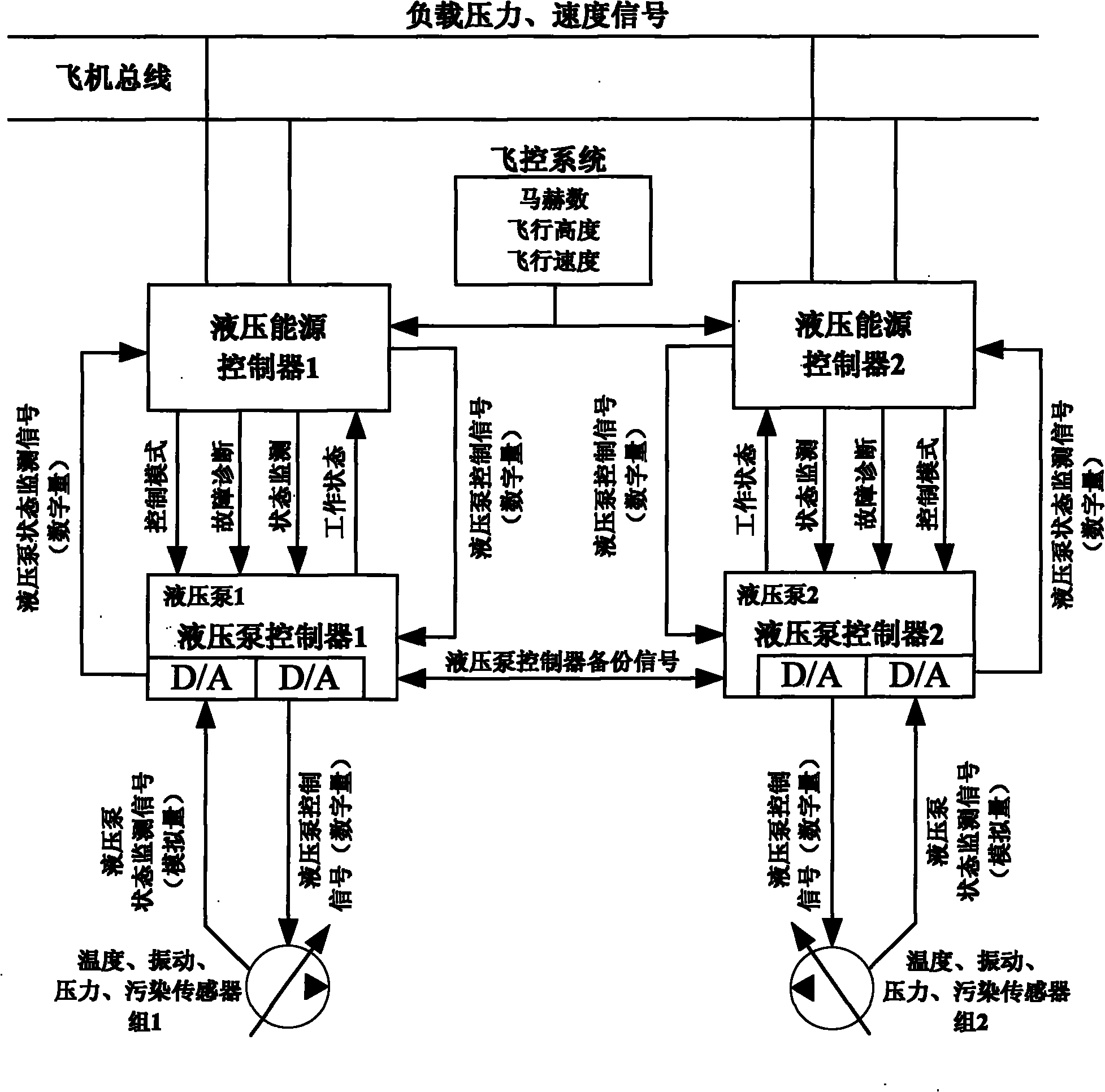

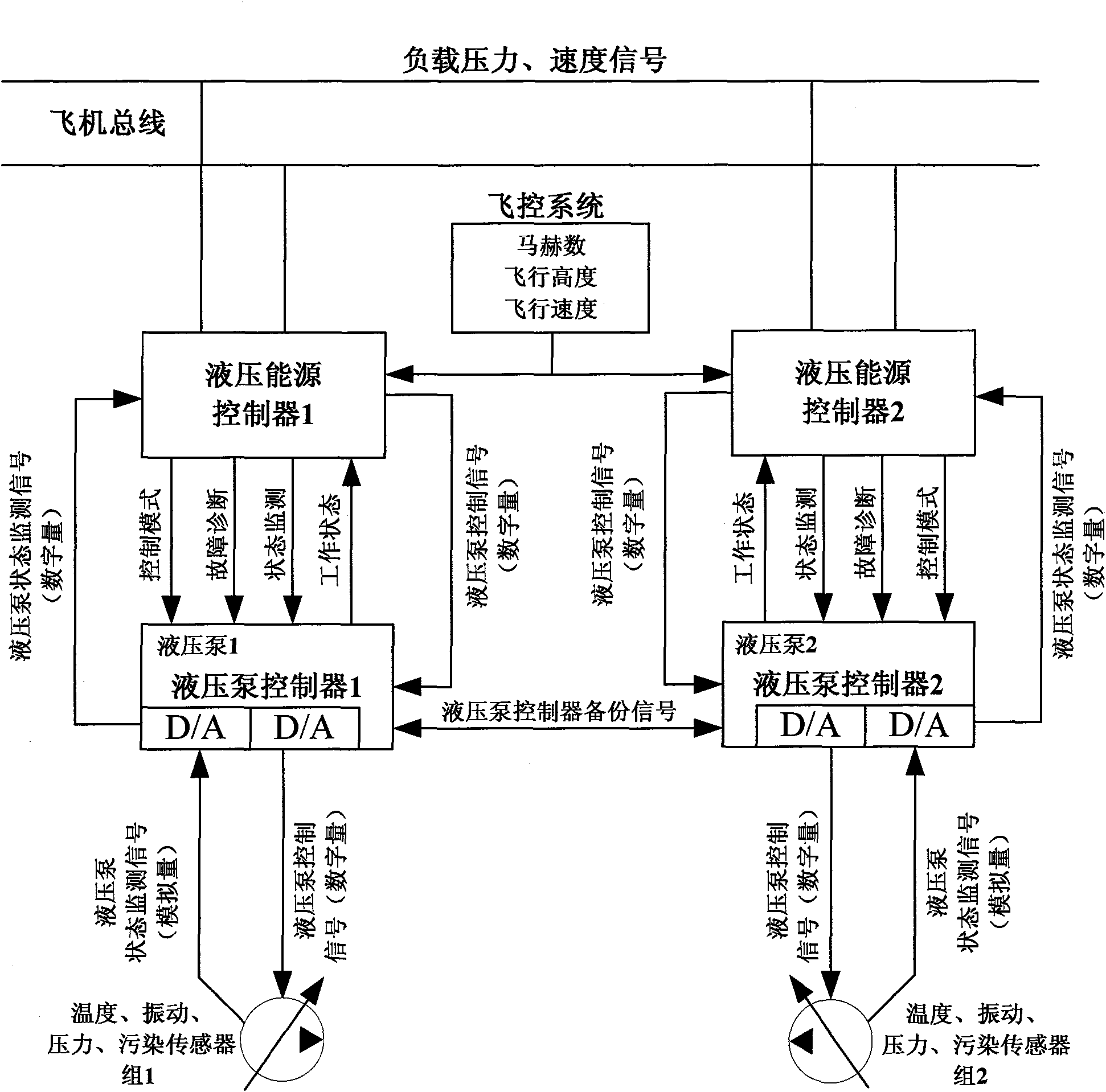

[0017] Referring to Fig. 1, the variable pressure hydraulic energy system consists of three parts: hydraulic pump, hydraulic energy management control unit (including hydraulic energy controller and hydraulic pump controller) and vibration, temperature, pressure and pollution sensor groups, among which the hydraulic pump control The controller is integrated in the hydraulic pump.

[0018] The hydraulic pump is used as an actuator to generate hydraulic energy. The hydraulic energy management control unit issues working state instructions according to the flight state of the aircraft and the working state of the load to adjust the swash plate inclination angle of the hydraulic pump and the pressure regulating spring, so that the hydraulic pressure The pump can output hydraulic power (including output flow and output pressure) that meets the needs of the user's system. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com