Separated type heat-pipe plate solar collector and special working refrigerant thereof

The technology of a solar panel and a split heat pipe is applied in the field of solar energy utilization, which can solve the problems of high cost, difficult to popularize, and cannot be used, and achieves the effects of simple structure, easy popularization and application, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

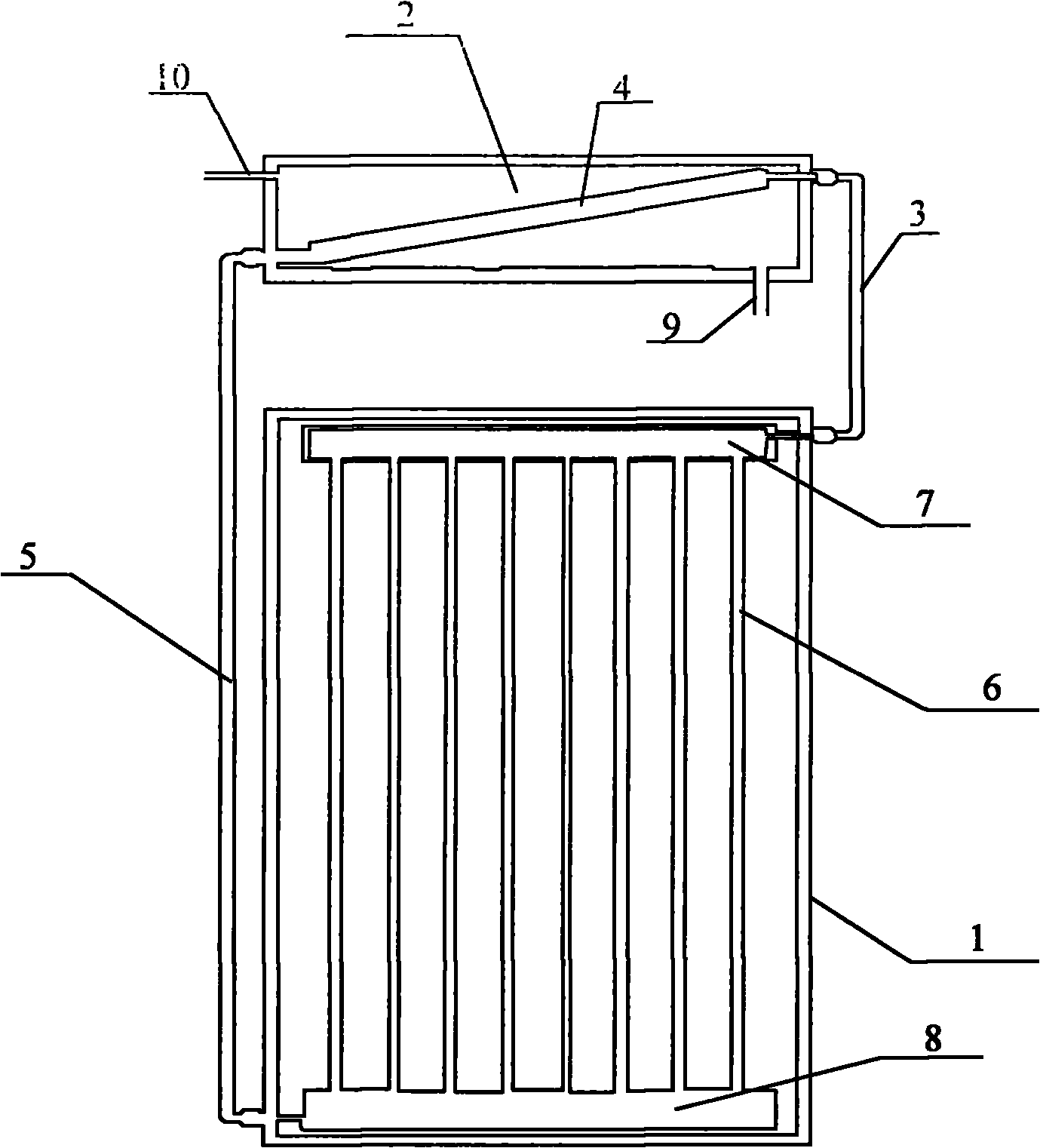

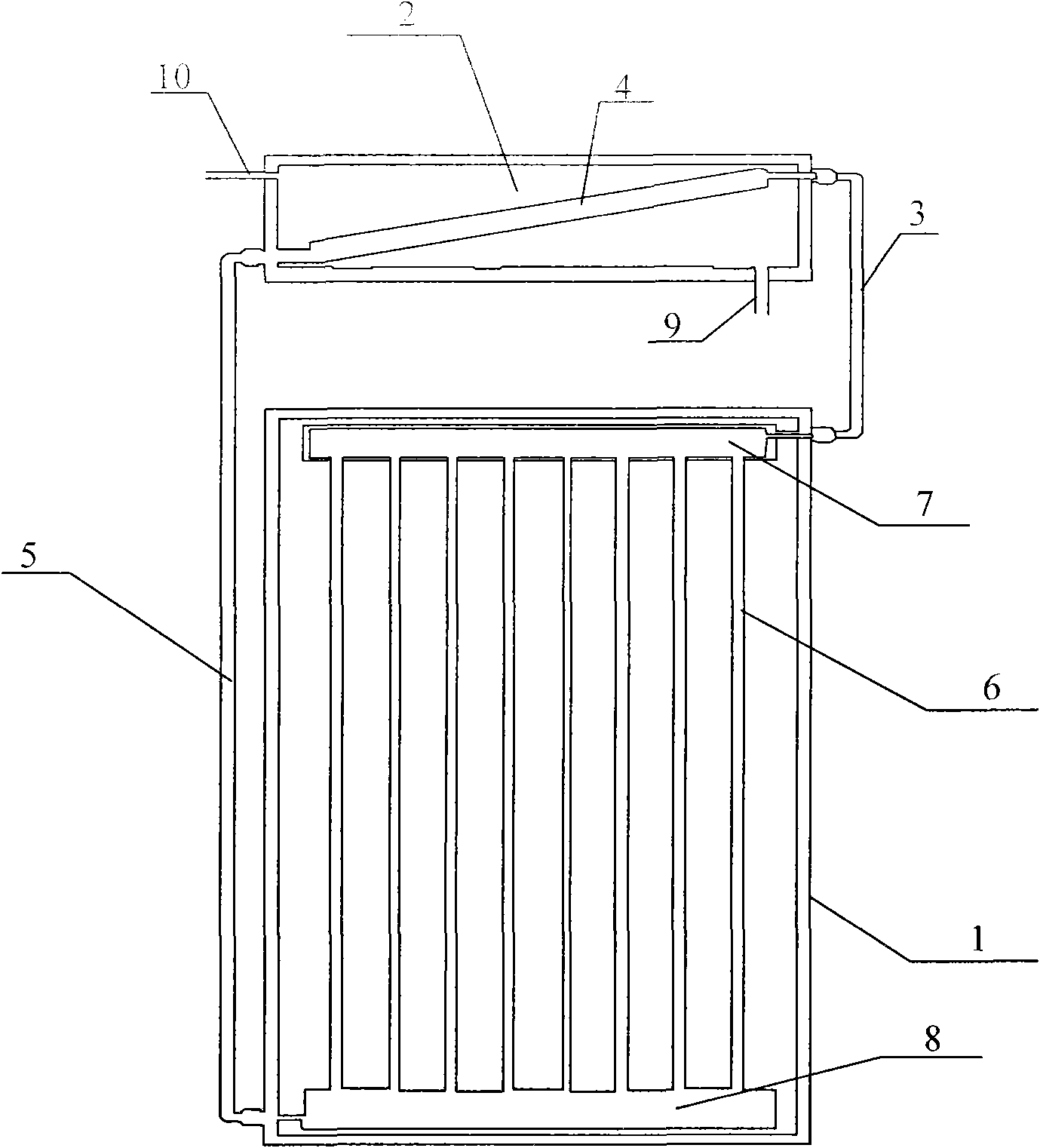

[0025] As shown in Figure 1, the split-type heat pipe solar panel collector consists of a collector frame 1, a working fluid circulation loop and a heat storage bin 2, and the collector frame 1 and heat storage bin 2 pass through the working fluid circulation loop connect them.

[0026] The working fluid circulation circuit is formed by sequentially connecting the heat pipe evaporator, the steam rising pipe 3, the condensing pipe 4, and the liquid descending pipe 5. Hot water outlet pipe 10. The lower end of the condensing pipe 4 communicates with the liquid downcomer 5 , and the higher end communicates with the steam upcomer 3 .

[0027] The heat pipe evaporator is composed of an evaporator vertical pipe 6 , a steam cavity 7 located above the evaporator vertical pipe 6 and communicating with it, and a liquid collection chamber 8 located below the evaporator vertical pipe 6 and communicating therewith. And the steam chamber 7 communicates with the steam ascending pipe 3 , an...

Embodiment 2

[0032] The utility model relates to a working fluid specially used in a split-type heat pipe solar panel heat collector, and the working fluid is a multiphase composite working fluid.

[0033] The multi-phase-change composite working fluid is one or more of liquid-gas phase-change substances or solid-liquid phase-change substances.

[0034] The liquid-gas phase change substance is one or more of water, ammonia, pentane, acetone, methanol, ethanol, and heptane.

[0035] The solid-liquid phase change substance is one or more of inorganic water and salts, fatty acids, alkali metals, high-temperature molten salts, higher aliphatic hydrocarbons, alcohol polyhydrocarbyls, and compound salts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com