Gallium nitride based avalanche detector and preparation method thereof

A gallium nitride-based, manufacturing method technology, applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems affecting the development and application of gallium nitride UV detectors, the mutual restriction of detection sensitivity and dark current, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

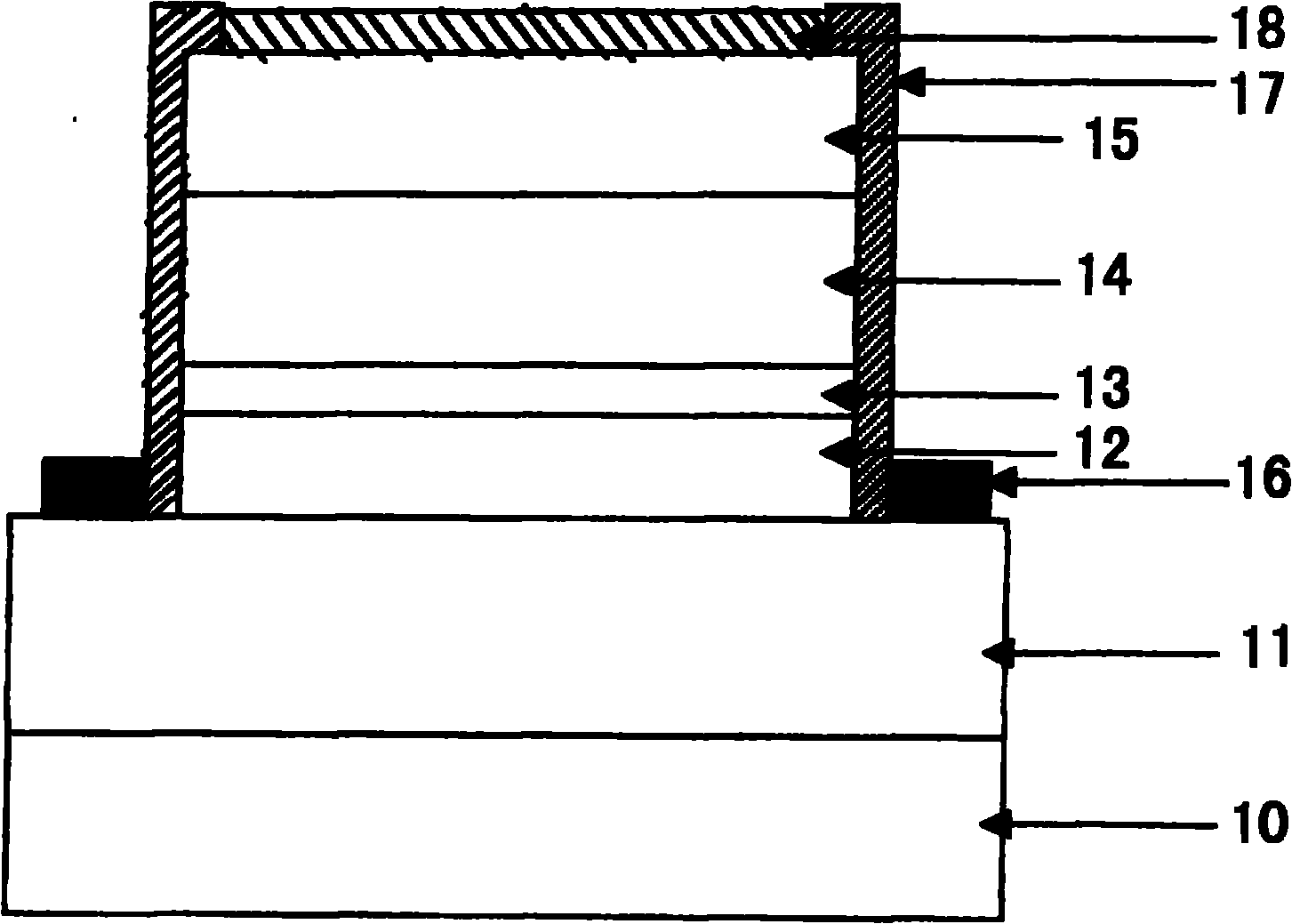

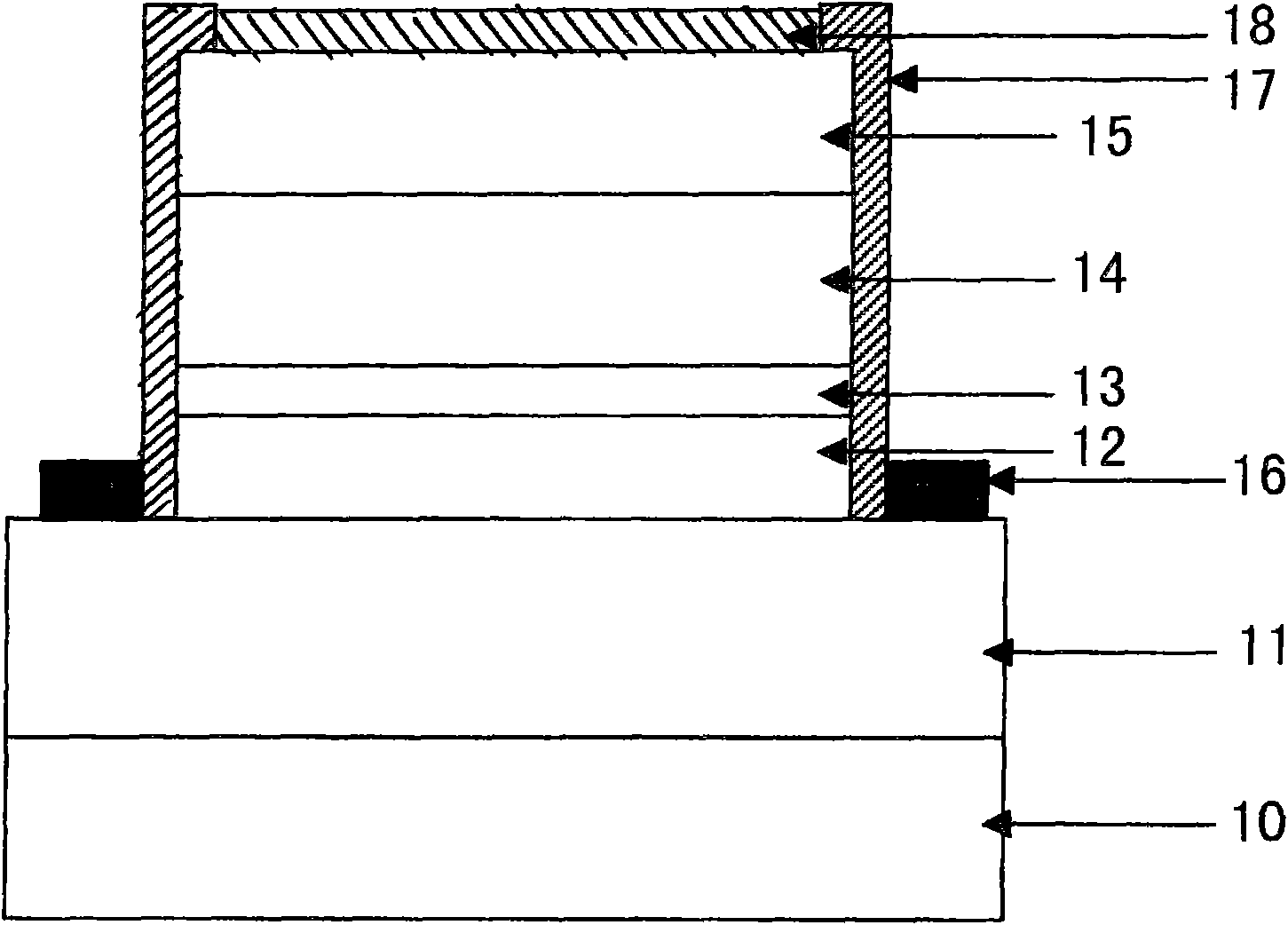

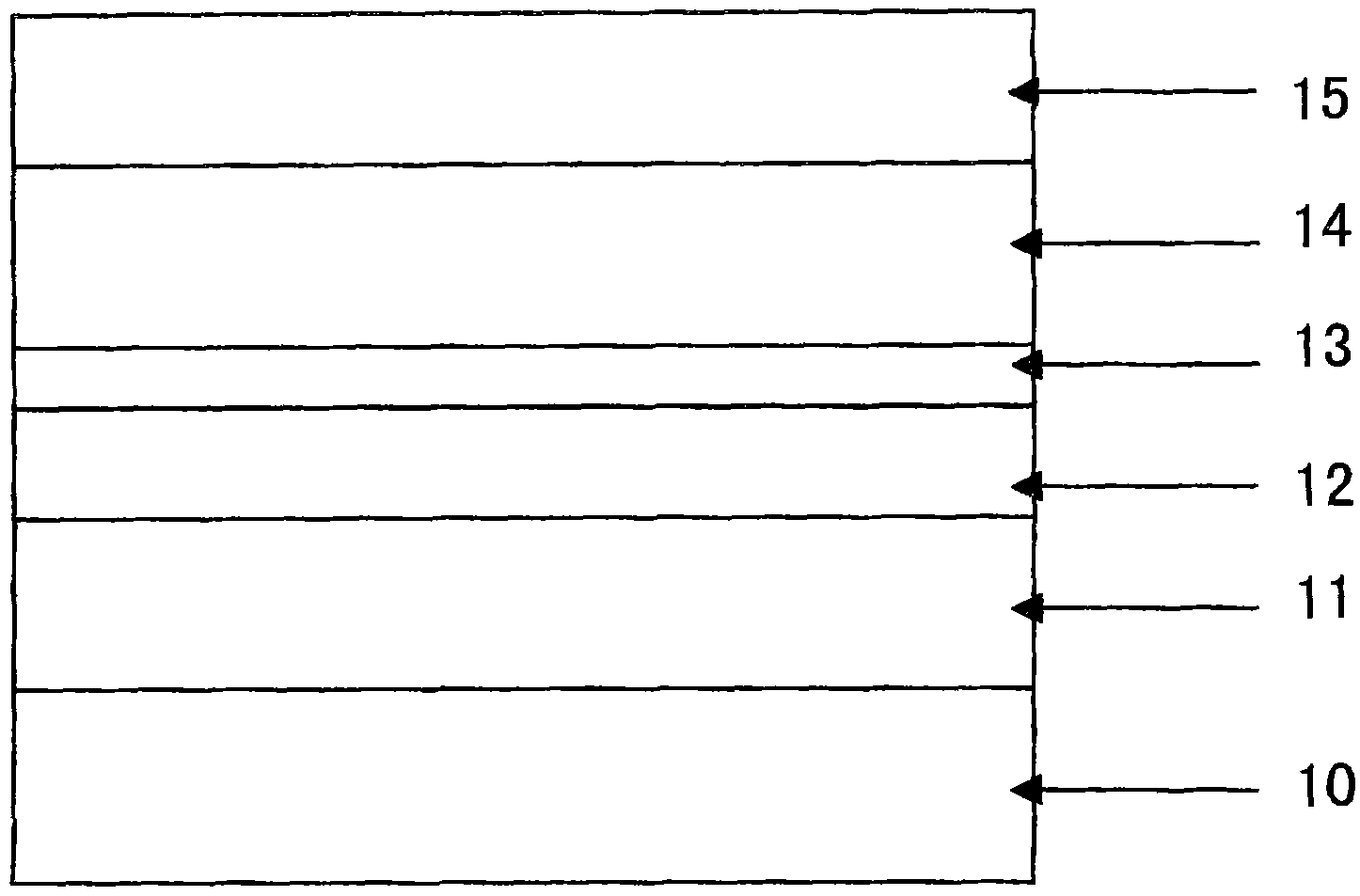

[0042] Please refer to Fig. 1 and Fig. 2, a gallium nitride-based avalanche detector with a positively irradiated absorbing layer and a multiplication layer separated by the present invention includes:

[0043] A substrate 10, the substrate 10 is sapphire, gallium nitride, silicon, silicon carbide or gallium arsenide material which is conducive to the epitaxial growth of group III nitrides;

[0044] An N-type doped GaN ohmic contact layer 11, the N-type doped GaN ohmic contact layer 11 is fabricated on the substrate 10;

[0045] An unintentionally doped GaN absorbing layer 12, the unintentionally doped GaN absorbing layer 12 is made on the N-type doped GaN ohmic contact layer 11, and the area of the unintentionally doped GaN absorbing layer 12 is smaller than that of the N-type doped The area of the GaN ohmic contact layer 11. This layer acts as an absorbing layer for light in the detector response band (photon energy is between the band gaps of GaN and AlGaN);

[0046] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com