Structure of light emitting diode chip and manufacture method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of low light-emitting efficiency of chips, restricting the development of LEDs, and limited efficiency improvement, so as to improve side wall light-emitting technology and improve light-emitting efficiency , Improve the effect of brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

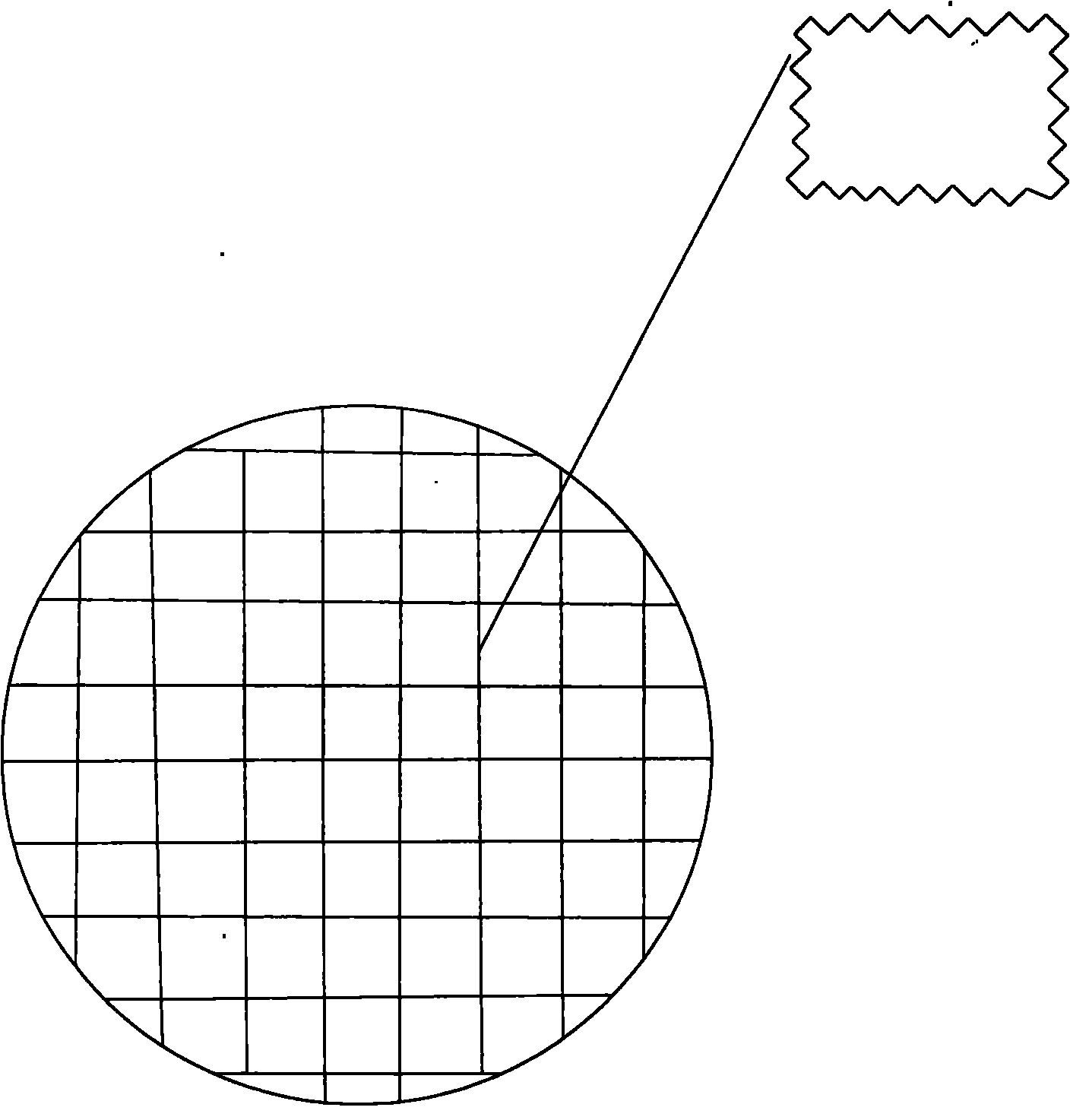

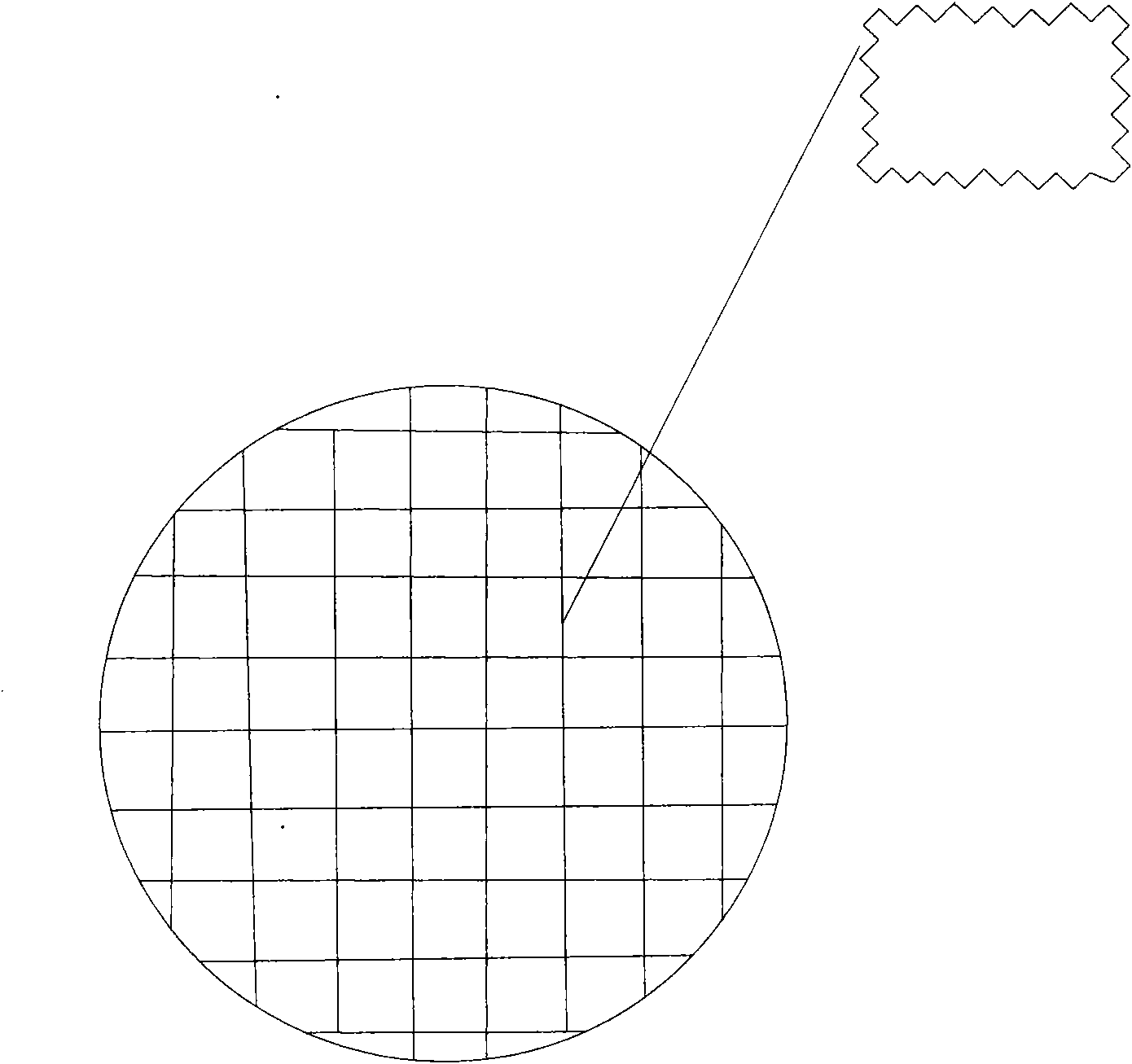

[0039] Step A, first use the laser scribing process to scribe on the growth substrate and form aisles, by adjusting the pulse frequency of the laser source (adjusting the laser frequency, the continuous laser source becomes a discontinuous laser source, which is equivalent to that of the growth substrate. The surface is dotted, the frequency of a normal dicing machine is 100KHZ, and the laser frequency of the present invention is below 30KHZ. The edge of the cross section (section perpendicular to the epitaxial growth direction) of the growth substrate is divided into zigzag or wave shape.

[0040] The aisle directly divides the surface of the growth substrate into small areas identical to the final chip size, defines the chip size (defining the growth substrate), and forms an aisle depth of 15-50 microns; the preferred range of the general aisle depth is 15- 20 microns, and the preferred aisle depth is around 20 microns. The growth substrate may be a Si growth substrate, a Si...

Embodiment 2

[0049] Step A, first growing a semiconductor epitaxial layer on a growth substrate. Patterns can be formed on the growth substrate by using techniques such as photolithography and dry etching technology or wet etching technology to make a patterned growth substrate. An N-type semiconductor layer, an active layer, and a P-type semiconductor layer are epitaxially grown sequentially on the patterned growth substrate. The N-type semiconductor layer is preferably an N-type GaN layer, the P-type semiconductor layer is preferably a P-type GaN layer, and the active layer is preferably a GaN-based quantum well layer.

[0050] Step B, by adjusting the pulse frequency of the laser source (adjust the laser frequency so that the continuous laser source becomes an intermittent laser source, which is equivalent to dotting on the surface of the growth substrate), the pulse frequency of the laser source is 20KHZ, and the semiconductor epitaxy The edges of the cross-section (section perpendicu...

Embodiment 3

[0055] The difference between the third embodiment and the second embodiment is only that the semiconductor epitaxial layer is adjusted by adjusting the pulse frequency of the laser source (adjusting the laser frequency to make the continuous laser source become a discontinuous laser source, which is equivalent to dotting the surface of the growth substrate). And the edge of the cross section of the growth substrate (the cross section perpendicular to the epitaxial growth direction) is drawn into a zigzag or wave shape, and the pulse frequency of the laser source is 25KHZ. That is, the sidewalls of the semiconductor epitaxial layer and the growth substrate are both wavy.

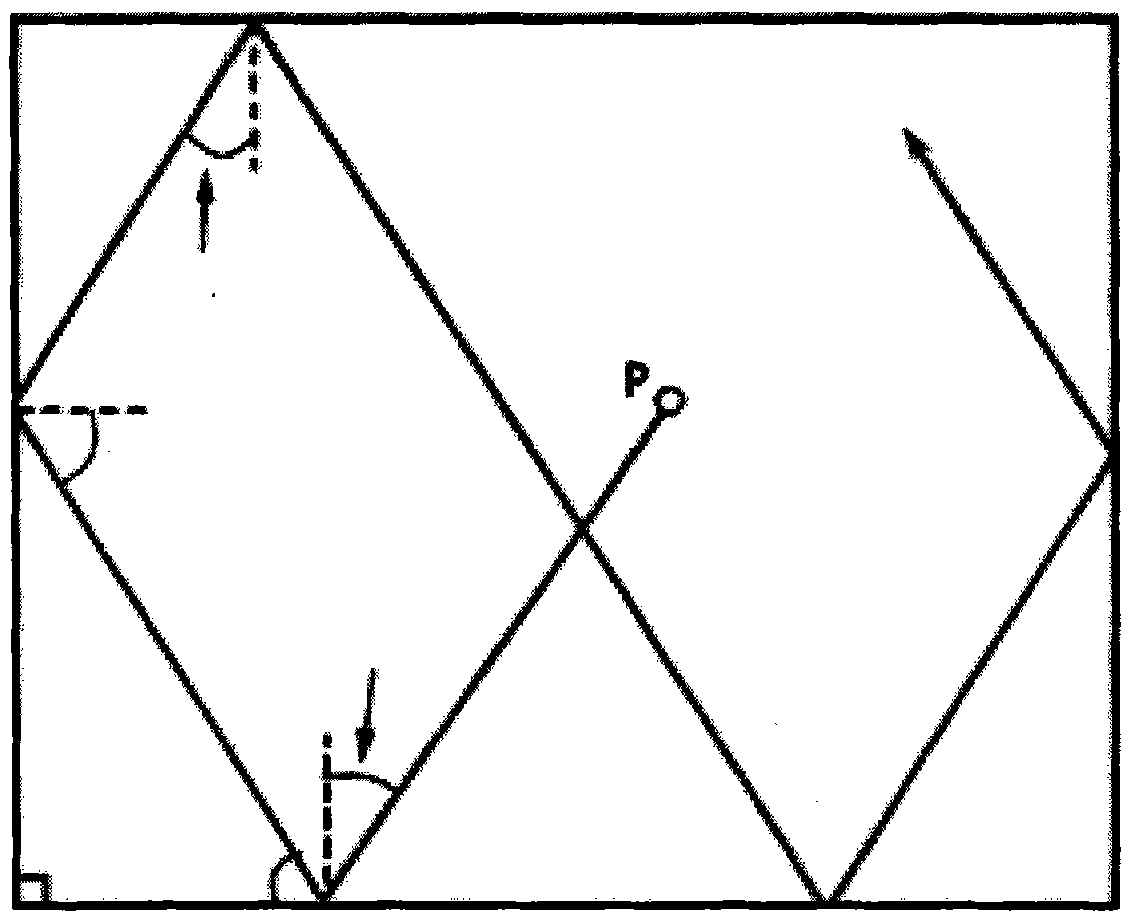

[0056] Please refer to Fig. 2, since the sidewall of a conventional chip is vertical, when the radiated photon P is at an incident angle θ 1 Arriving at the first wall w1, after reflection, it will be at the incident angle θ 2 Reaching the second wall w2 (i.e. the side wall), after reflection again, it will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com