Method for rapidly degrading decabromodiphenyl oxide in organic series by nano Pd/C catalyst

A technology for rapid degradation of decabromodiphenyl ether, which is applied in the field of rapid degradation of decabromodiphenyl ether, can solve the problems of short degradation time and inability to degrade decabromodiphenyl ether, and achieve easy control of conditions, shorten degradation time, and operate simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Performance index of nano-Pd / C powder catalyst

[0026] The mass percentage of Pd is 5.0±0.05%, the particle size is 2.5nm; the particle size of C is 74~104μm, and the specific surface area is ≥1100m 2 / g, metal surface area 50~65m 2 / g. SEM photo figure 1 shown.

[0027] (2) Types of solvent and hydrogen source: a mixed solution of n-hexane, isopropanol and methanol is the solvent, wherein n-hexane / isopropanol / methanol=100:99:1 (volume ratio), and isopropanol is the main hydrogen source.

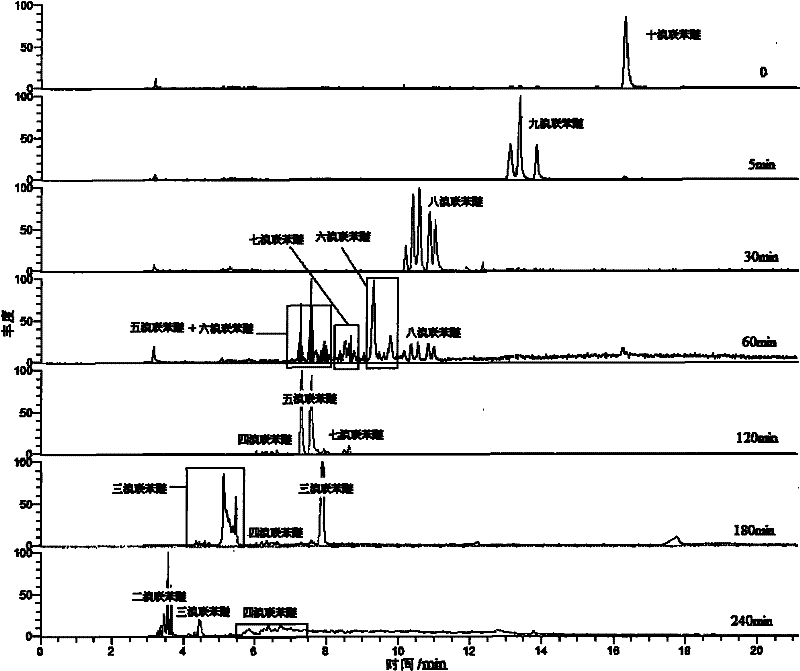

[0028] (3) Debromination degradation reaction of decabromodiphenyl ether

[0029] Sodium hydroxide or potassium hydroxide is added to the mixed solution of decabromodiphenyl ether in n-hexane / isopropanol / methanol with a concentration of 100 mg / l to adjust the pH value of the reaction system to between 10 and 11. Take 5ml of the above reaction solution into a 25ml serum bottle, add 30mg of Pd / C powder, and finally put it into a stirrer, tighten the lid, and wrap it in tinfoil...

Embodiment 2

[0040] (1) Nano Pd / C powder catalyst performance index, same as embodiment 1.

[0041] (2) Types of solvent and hydrogen source: toluene, a mixed solution of isopropanol and methanol is a solvent, wherein toluene / isopropanol / methanol=100:99:1 (volume ratio), and isopropanol is the main hydrogen source.

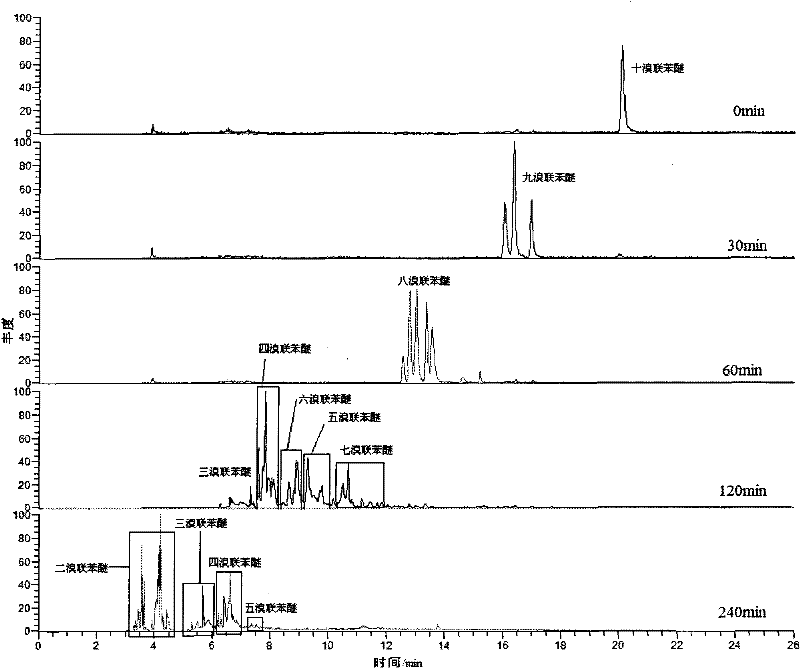

[0042] (3) Debromination degradation reaction of decabromodiphenyl ether

[0043] Potassium hydroxide was added to the toluene / isopropanol / methanol reaction solution of decabromodiphenyl ether with a concentration of 498 mg / l to adjust the pH value of the reaction system to between 10 and 11. Take 5ml of the above reaction solution into a 25ml serum bottle, add 40mg of Pd / C powder, and finally put it into a stirrer, tighten the lid, and wrap it in tinfoil to avoid light. The reaction was carried out in a constant temperature magnetic stirrer. When the temperature of the water in the water bath rose to 50° C., the serum bottle was placed in it, and the reaction was started by ...

Embodiment 3

[0045] (1) Nano Pd / C powder catalyst performance index, same as embodiment 1.

[0046] (2) Type of hydrogen source: the mixed solution of isopropanol and methanol is the hydrogen source, wherein isopropanol / methanol=99:1 (volume ratio), and isopropanol is the main hydrogen source.

[0047] (3) Debromination degradation reaction of decabromodiphenyl ether

[0048] Add an equal volume of isopropanol / methanol solution in the waste TV casing pyrolysis oil of decabromodiphenyl ether at a concentration of 100mg / l, and the volume ratio of waste and old TV casing pyrolysis oil, isopropanol and methyl alcohol is 100: 99:1 (25ml of waste TV shell pyrolysis oil, 24.75ml of isopropanol, and 0.25ml of methanol). The main composition of the waste TV shell pyrolysis oil is shown in Table 1. It can be seen that the pyrolysis oil is a complex system with aromatic hydrocarbon substance styrene as the main component, and its content in the pyrolysis oil is 37.87%. . The relative content in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com