Self-leveling mortar anti-shrinking agent and preparation method and application thereof

The technology of self-leveling mortar and anti-shrinkage agent is applied in the field of self-leveling mortar anti-shrinkage agent, which can solve the problem of not being fully applicable, and achieve the effects of improving deformation resistance and increasing flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

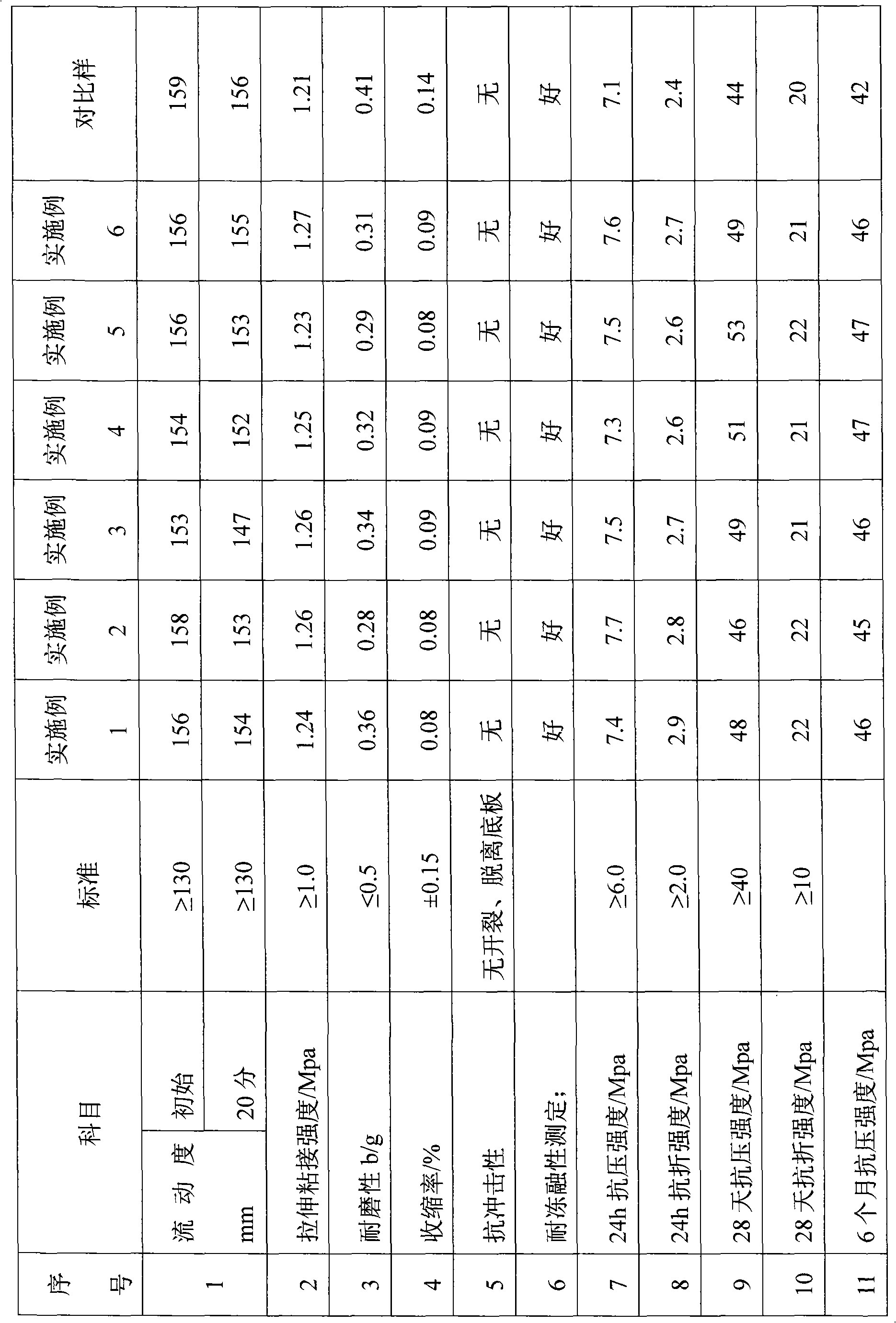

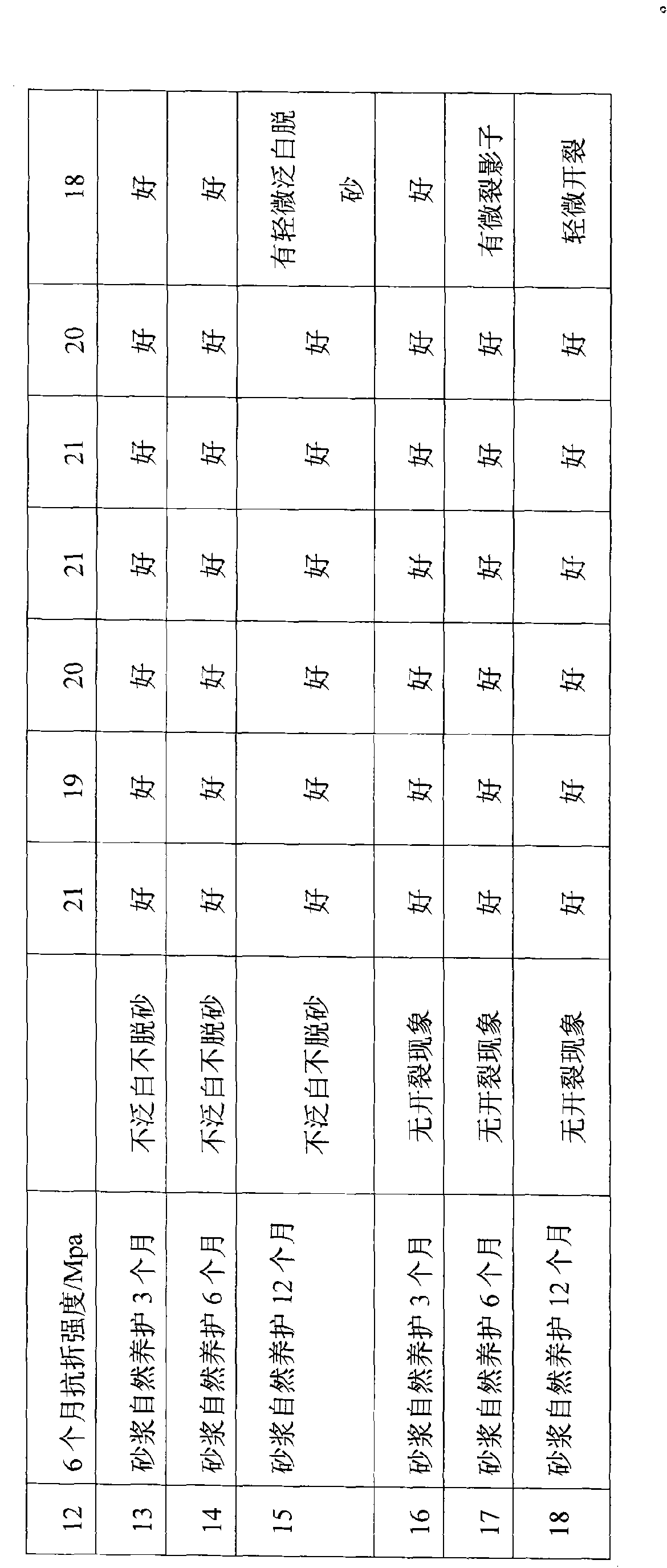

Examples

Embodiment 1

[0028] 80 parts of bauxite, 6 parts of sodium carbonate, 0.5 parts of cerium trichloride, 100 parts of zeolite, 10 parts of natural alunite, 40 parts of dihydrate gypsum, N-2-(aminoethyl)-3-aminopropyl trimethyl 1.5 parts of oxysilane.

[0029] (1) Preparation of component A, mix bauxite and sodium carbonate and calcine at 350°C for 3 hours, after cooling, grind the mixture with a grinder until the average particle size is 500 mesh, and then put the powder in the mixing tank Internally heated to about 80°C, spray the cerium trichloride ethanol solution with a weight concentration of 3.5% on the powder, stir for 1 hour, and evaporate the ethanol;

[0030] (2) Preparation of component B. Put zeolite powder, natural alunite, and dihydrate gypsum into a grinder to grind to a fineness of 400 meshes, then put the powder in a mixing kettle and heat it to about 90°C. % N-2-(aminoethyl)-3-aminopropyltrimethoxysilane ethanol solution is sprayed on the powder, stirred for 1 hour, the et...

Embodiment 2

[0032] 90 parts of bauxite, 7 parts of sodium carbonate, 1 part of cerium trichloride, 100 parts of zeolite, 12 parts of natural alunite, 45 parts of dihydrate gypsum, N-2-(aminoethyl)-3-aminopropyl trimethyl 2 parts of oxysilane.

[0033] (1) Preparation of component A, mix bauxite and sodium carbonate and calcine at 380°C for 3 hours, after cooling, use a grinder to grind the mixture to an average particle size of 600 mesh, and then put the powder in the mixing kettle Heat to about 80°C, spray cerium trichloride ethanol solution with a weight concentration of 5% on the powder, stir for 1 hour, and evaporate the ethanol;

[0034] (2) Preparation of component B, put zeolite powder, natural alunite, and dihydrate gypsum into a grinder and grind to an average particle size of 400 mesh fineness, then put the powder in a mixing kettle and heat it to about 90°C, and the weight A 12% ethanol solution of N-2-(aminoethyl)-3-aminopropyltrimethoxysilane was sprayed on the powder and st...

Embodiment 3

[0036] 100 parts of bauxite, 8 parts of sodium carbonate, 1.5 parts of cerium trichloride, 100 parts of zeolite, 15 parts of natural alunite, 50 parts of dihydrate gypsum, N-2-(aminoethyl)-3-aminopropyl trimethyl 3 parts of oxysilane.

[0037] (1) Preparation of component A, mix bauxite and sodium carbonate and calcinate at 400°C for 3 hours, after cooling, grind the mixture to 400 mesh fineness with a grinder, and then heat the powder in a mixing kettle At about 80°C, spray cerium trichloride with a weight concentration of 8% on the powder with ethanol solution, stir for 1 hour, and evaporate the ethanol;

[0038] (2) Preparation of component B, put zeolite, natural alunite, and dihydrate gypsum into a grinder to grind to a fineness of 600 mesh, then put the powder in a mixing kettle and heat it to about 90°C, and set the weight concentration to 8% The ethanol solution of N-2-(aminoethyl)-3-aminopropyltrimethoxysilane was sprayed on the powder, stirred for 1 hour, and the et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com