Buoyancy measurement principle based pulp concentration meter

A measurement principle and concentration meter technology, which is applied in the direction of material analysis through observation of sunken objects, can solve the problems of high requirements for ore slurry conditions, influence of test results, and many human factors, so as to improve production indicators and recovery rate, and simple structure , simple working principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

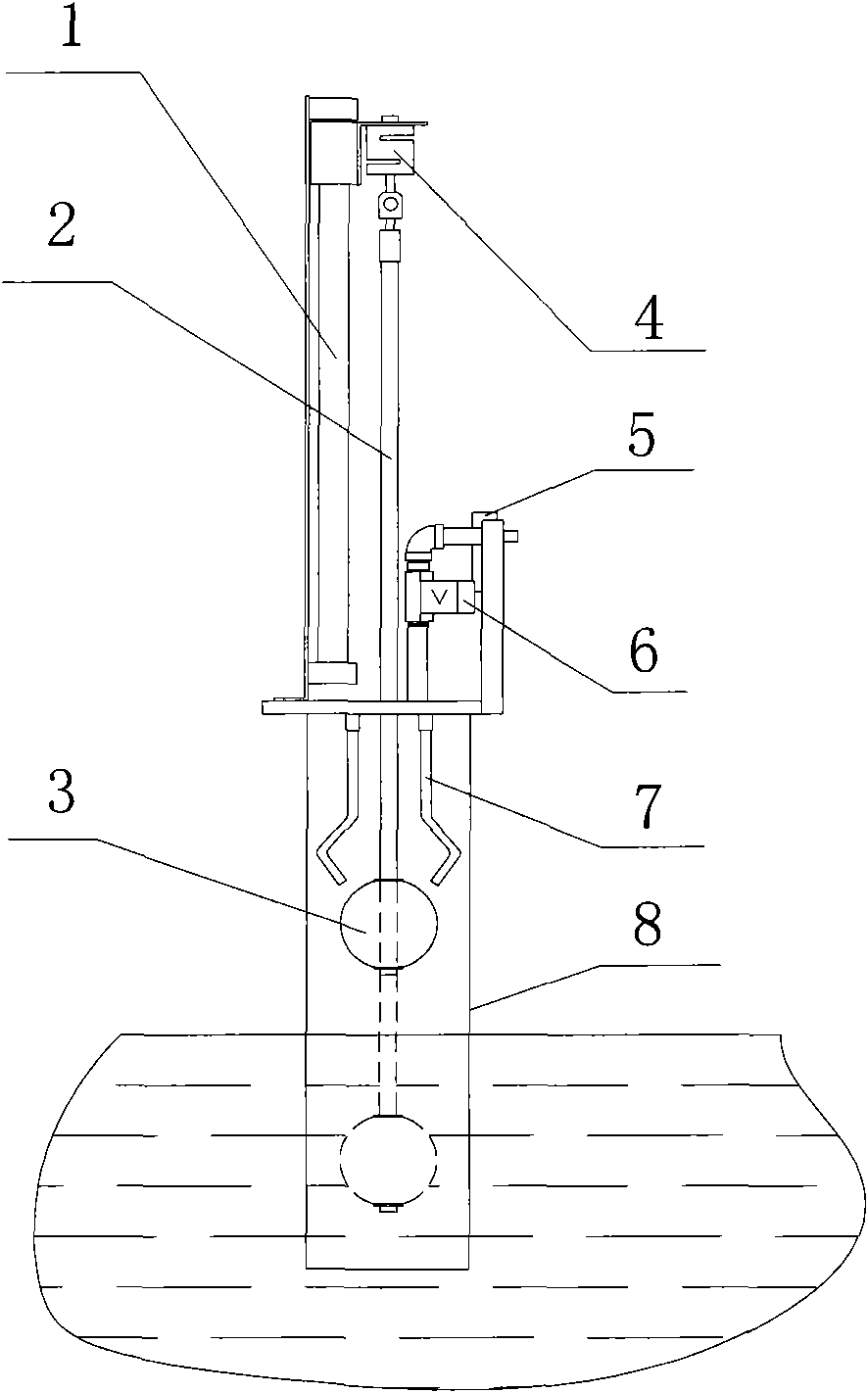

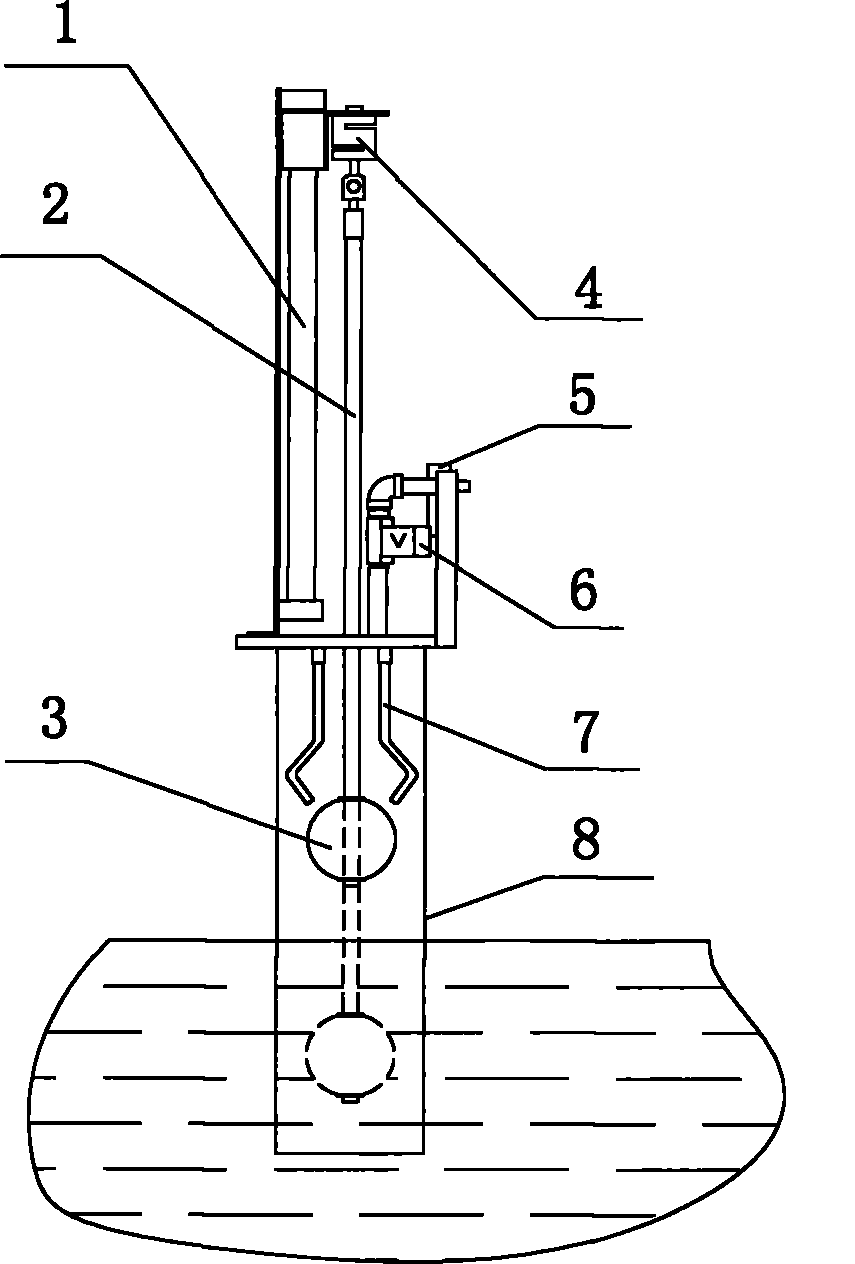

[0040] The slurry concentration meter of this embodiment consists of an actuator (1), a lifting rod (2), a float (3), a sensor (4), a signal converter (5), a water valve (6), a flushing water pipe (7), Isolation barrel (8) constitutes, see for details figure 1 shown.

[0041] The actuator (1) is an electric push rod, and the sensor (4) is a tension-compression load cell; the output end of the actuator (1) is connected to the sensor (4), and the lower end of the sensor (4) is connected to the lifting rod (2) ) upper end connection, a floating ball (3) is fixed at the lower end of the lifting rod (2), a flushing water pipe (7) is arranged above the floating ball (3), a water valve (6) is set on the flushing water pipe (7), and the floating ball (3 ) is provided with an isolation bucket (8) around.

[0042] The signal converter (5) is arranged on the pulp concentration meter through a bracket, and is used for converting the pressure signal measured by the sensor (4) into an ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com