Analytical method for component segregation of continuous casting slab

A composition segregation and analysis method technology, which is applied in the field of continuous casting slab composition segregation analysis by using metal in-situ analyzer, can solve the problems of inability to analyze other elements, weak representation, and inability to analyze other elements, etc., so as to reduce the detection time and cost, the preparation process is simple and fast, and the effect of accelerating the analysis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] Taking the Q345D continuous casting slab as an example, the thickness of the casting slab is D=250mm, and the width W=2100mm. The segregation analysis is carried out, and the specific chemical composition obtained from the analysis of the tundish is used as the analysis point. The composition is shown in Table 1.

[0031] Table 1. Chemical composition of test slabs (tundish analysis) %

[0032]

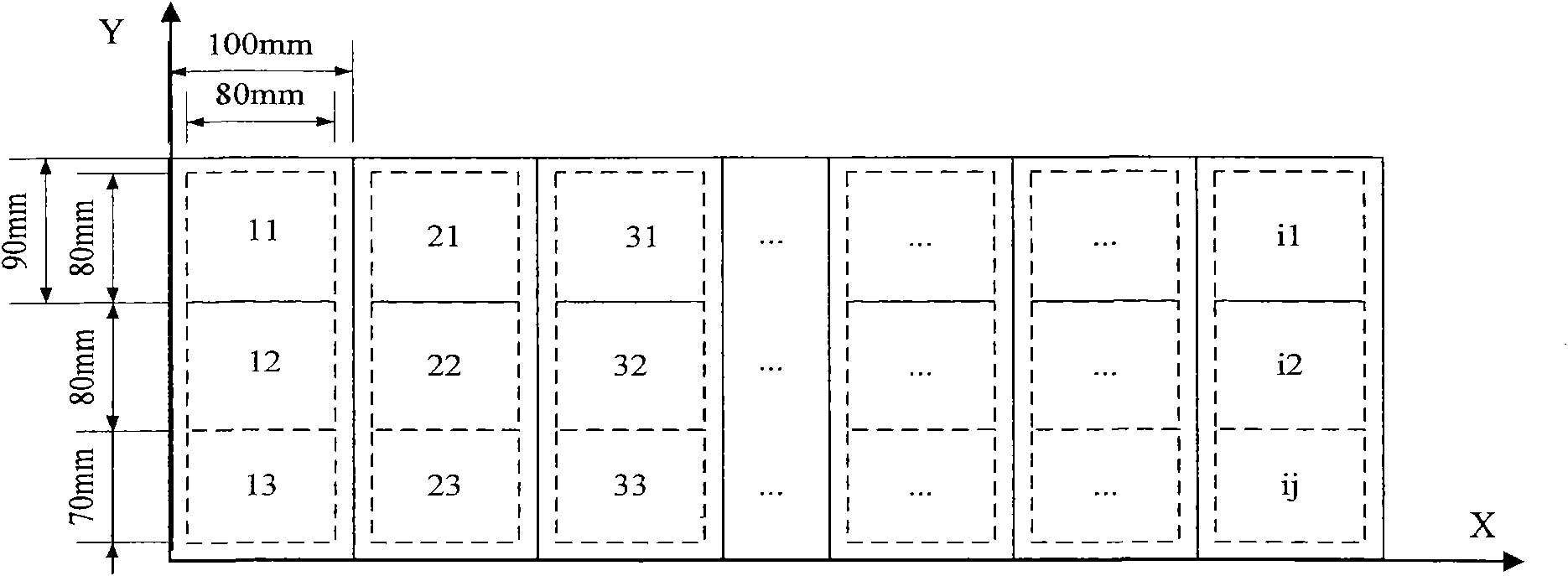

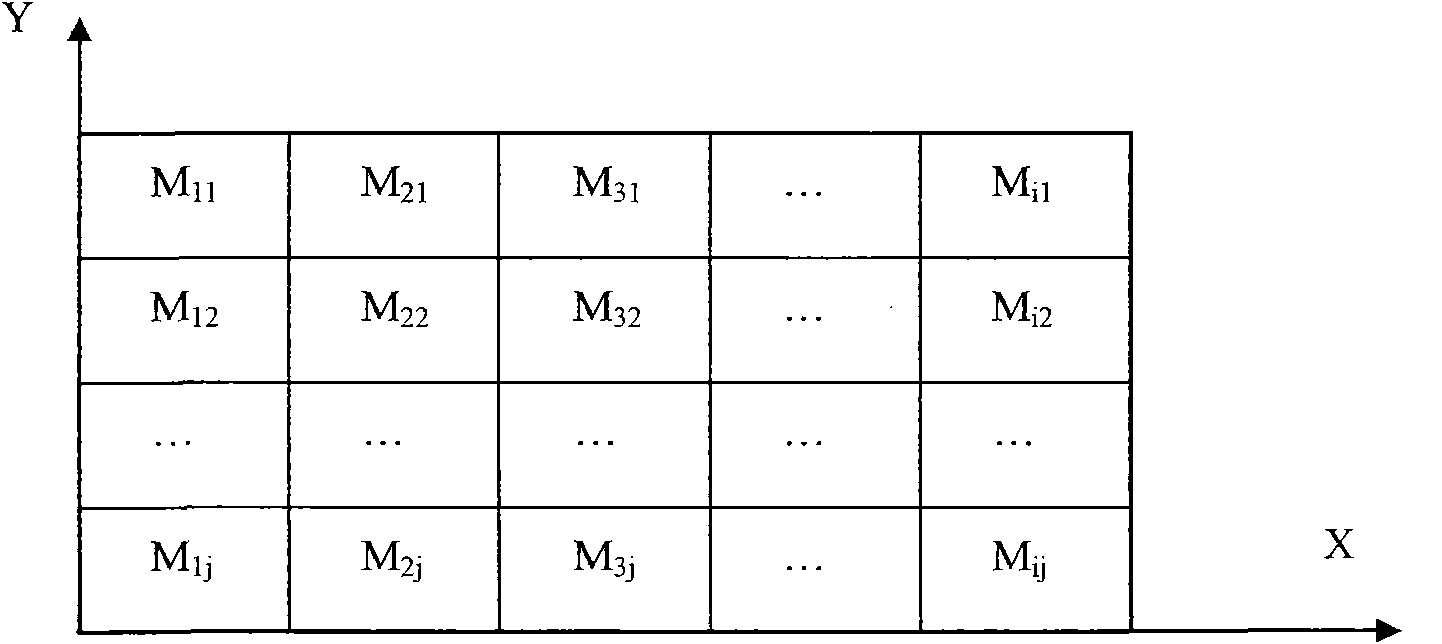

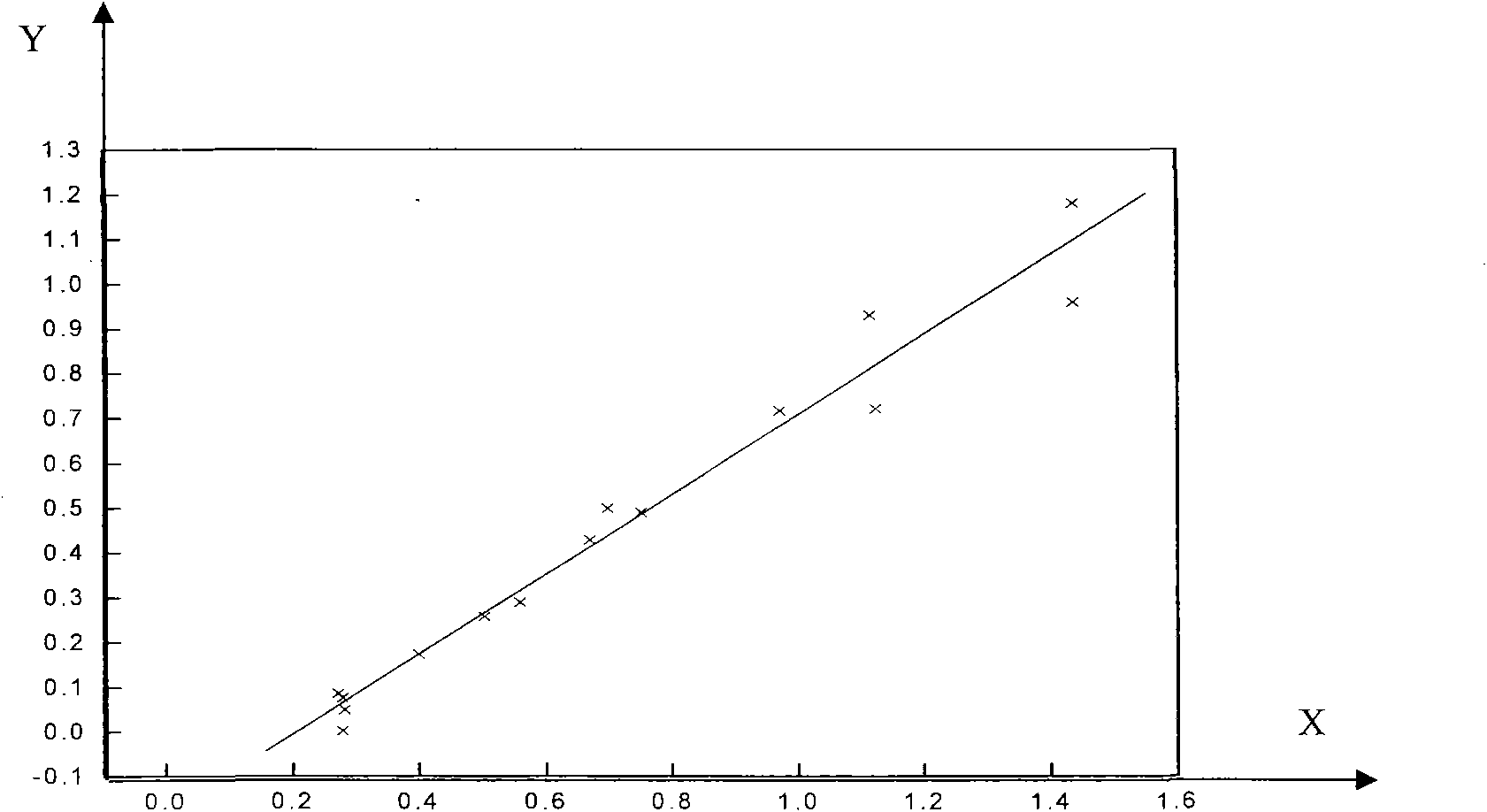

[0033] 1) Sample processing: the thickness of each sample is 10mm, according to figure 1 The sample is cut in the same way, the size of a single sample = 100×D=100×250mm, and a total of i=slab width W / 100=2100 / 100=21 samples are obtained, which are reprocessed by a milling machine to obtain a smooth surface and no pollution. The detection surface is ready for use. Each sample is scanned sequentially from the inner arc to the outer arc along the thickness direction j=(D-20) / 80=(250-20) / 80≈3 times, and the length of each scan is Y 1 =80mm, Y 2 =80mm, Y 3 =70mm, the scannin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com