Dual fluidized microcapsule granulating system

A dual-fluidization and granulation technology, applied in microcapsule preparation, microsphere preparation and other directions, can solve the problems of inability to meet the production line, irregular product particle shape, etc., to improve drying and coating efficiency, sufficient drying, coating high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

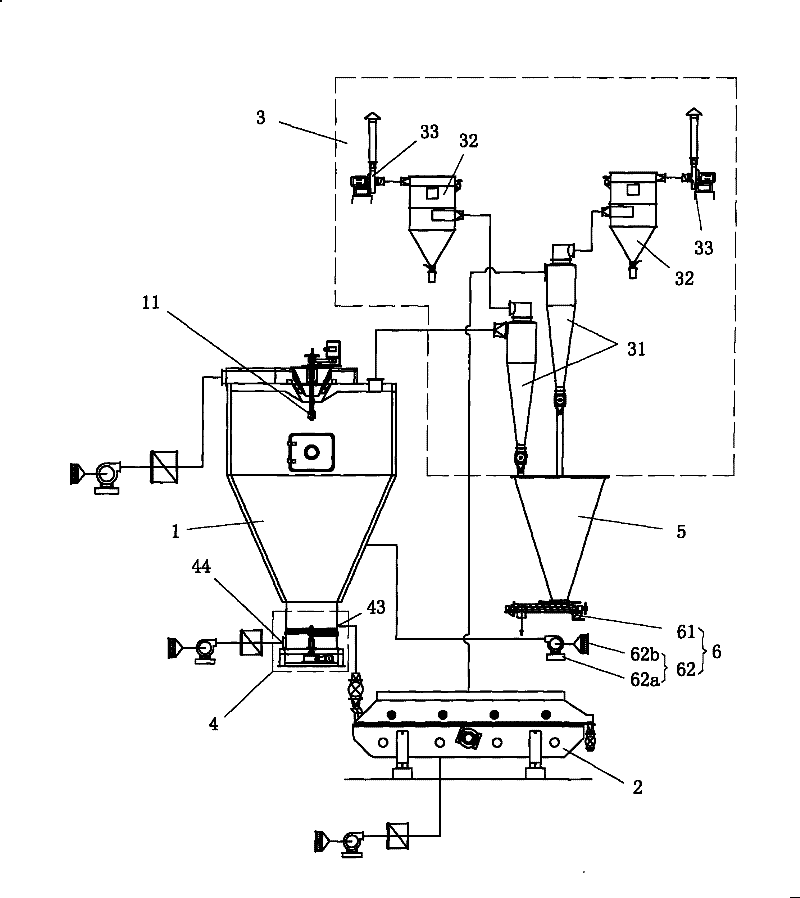

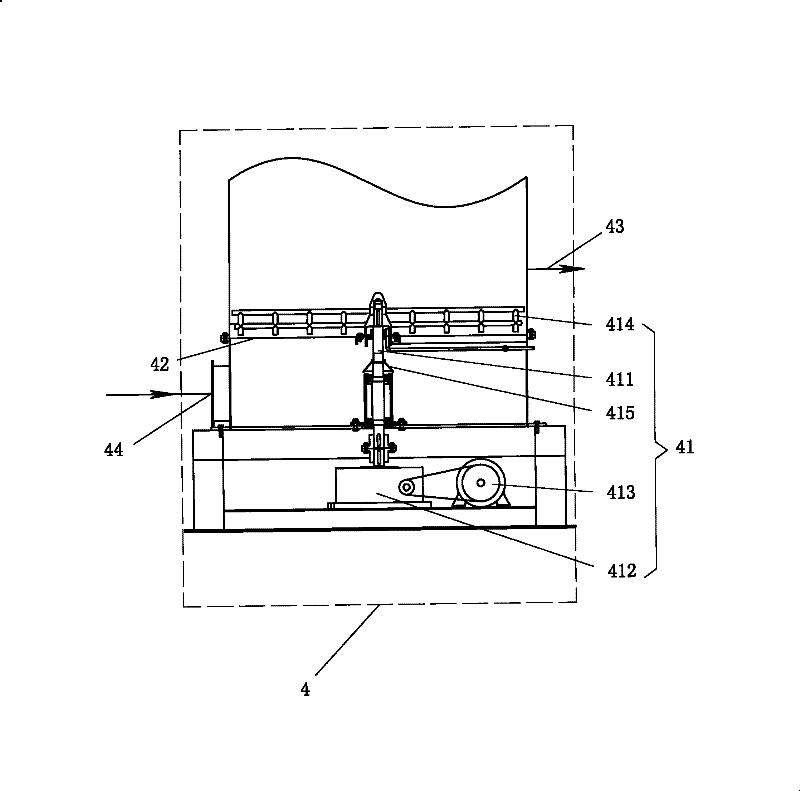

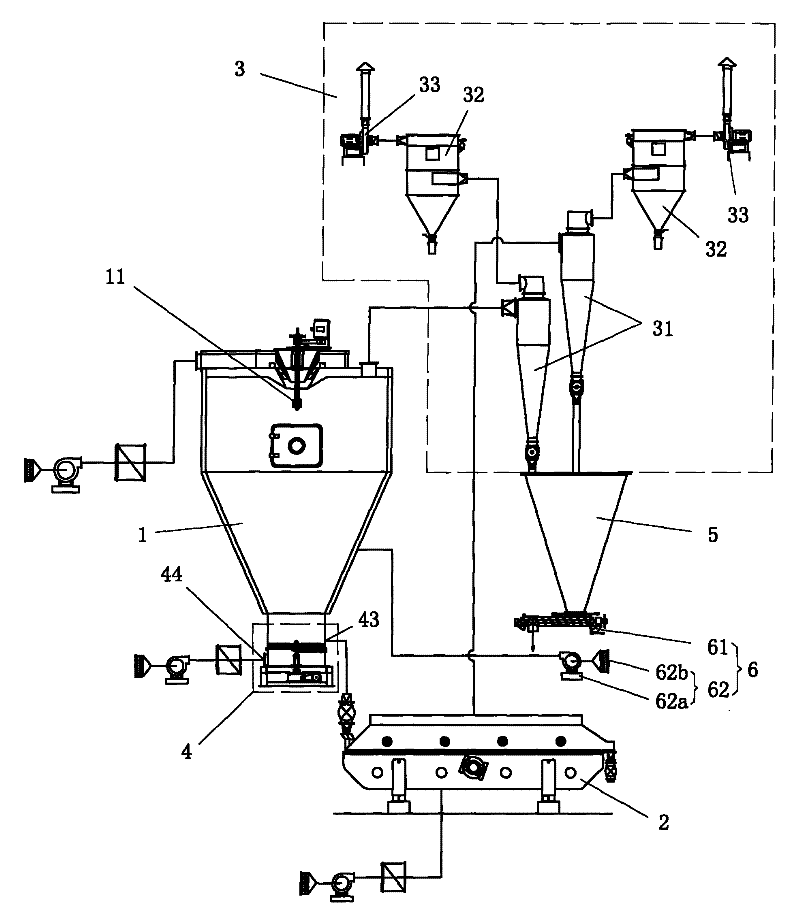

[0033] See figure 1 , the present invention has a granulation tower 1, an external fluidized bed 2 and a dust removal system 3; a granulation head 11 is arranged above the interior of the granulation tower 1, and the bottom of the granulation tower 1 is connected to the external fluidized bed 2 through a pipeline; its characteristics In that: the bottom of the granulation tower 1 is provided with a built-in fluidized bed 4, the discharge port 43 of the built-in fluidized bed 4 is connected to the external fluidized bed 2 through a material pipe, and the built-in fluidized bed 4 is provided with a stirring device 41 The microcapsule granulation system is also provided with a coated auxiliary material bin 5, the bottom of the coated auxiliary material bin 5 communicates with the middle part of the prilling tower 1 through a pipeline, and the pipeline between the bottom of the coated auxiliary material bin 5 and the middle part of the prilling tower 1 It is connected with the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com