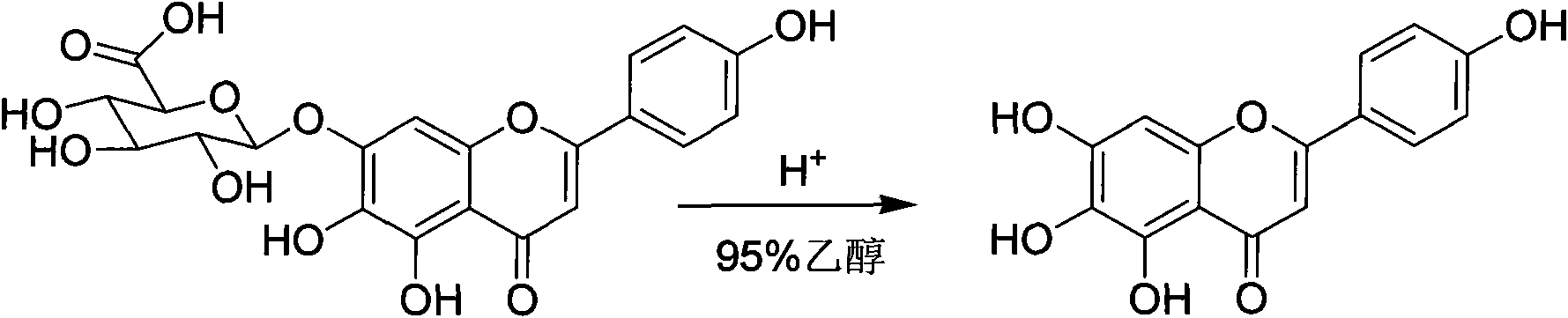

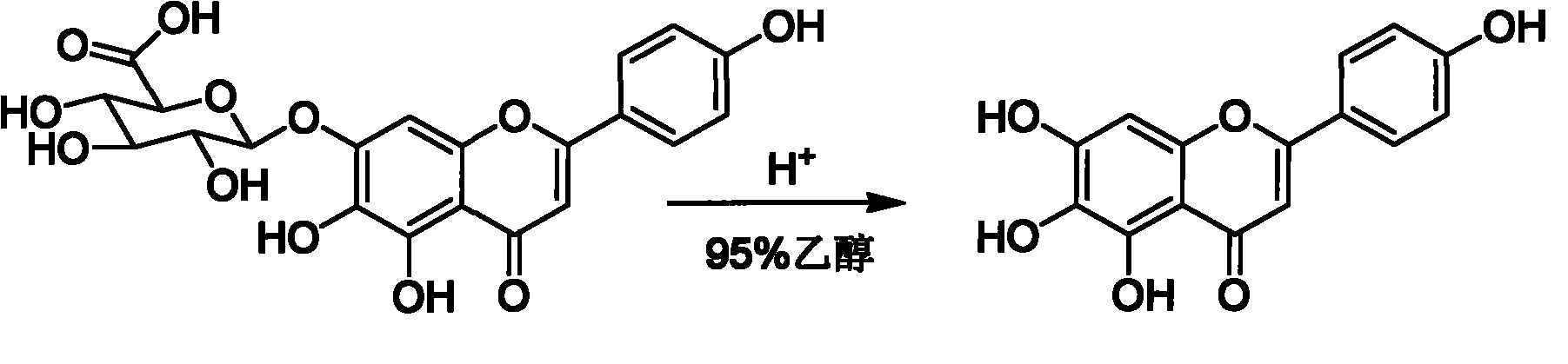

Method for preparing scutellarin aglycone

A technology of scutellarin aglycon and scutellarin, which is applied in the field of compound preparation, can solve the problems of low solubility of scutellarin and limitation of yield of scutellarin aglycone, and achieve high yield, high purity and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation of embodiment 1 scutellarin aglycon

[0031] (1) Get concentrated hydrochloric acid, join concentration and be configured into the concentrated hydrochloric acid ethanol solution that molar concentration is 4mol / L in 95% ethanol, standby;

[0032] (2) Add scutellarin to the alcoholic hydrochloric acid solution prepared in step (1), so that the concentration of scutellarin in the alcoholic hydrochloric acid solution is 0.05g / ml, and then reflux reaction at 80°C under nitrogen protection for 5 hours, and the reaction while stirring;

[0033] (3) After the reaction is over, take the reaction solution and evaporate half of the volume of ethanol, then add ice water with 5 times the volume of the reaction solution, cool and crystallize, suction filter after the crystallization is complete, get the solid and recrystallize it with ethyl acetate to obtain After crystallization, recrystallize with 80% methanol solution to obtain scutellarin aglycone with a yield ...

Embodiment 2

[0034] The preparation of embodiment 2 scutellarin aglycon

[0035] (1) Get concentrated hydrochloric acid, join concentration and be configured into the concentrated hydrochloric acid ethanol solution that molar concentration is 6mol / L in 95% ethanol, standby;

[0036] (2) Add scutellarin to the alcoholic hydrochloric acid solution prepared in step (1), so that the concentration of scutellarin in the alcoholic hydrochloric acid solution is 0.05g / ml, and then reflux reaction at 85°C under nitrogen protection for 5 hours, the reaction while stirring;

[0037] (3) After the reaction is over, take the reaction solution and evaporate half the volume of ethanol, then add 5 times the volume of ice water to the reaction solution, cool and crystallize, suction filter after the crystallization is complete, get the solid and recrystallize it with acetone to obtain the crystallized Then recrystallize with 80% ethanol solution to obtain scutellarin aglycone with a yield of 93% and a purity...

Embodiment 3

[0038] Example 3 Preparation of scutellarin aglycone

[0039] (1) Get concentrated hydrochloric acid, join concentration and be configured in the concentrated hydrochloric acid ethanol solution that molar concentration is 8mol / L in 95% ethanol, standby;

[0040] (2) Add scutellarin to the alcoholic hydrochloric acid solution prepared in step (1), so that the concentration of scutellarin in the alcoholic hydrochloric acid solution is 0.08g / ml, and then reflux reaction at 90°C under nitrogen protection for 4 hours, the reaction while stirring;

[0041] (3) After the reaction is over, take the reaction solution and evaporate half of the volume of ethanol, then add ice water with 5 times the volume of the reaction solution, cool and crystallize, suction filter after the crystallization is complete, get the solid and recrystallize it with ethyl acetate to obtain After crystallization, recrystallize with 90% ethanol solution to obtain scutellarin aglycone with a yield of 88%, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com